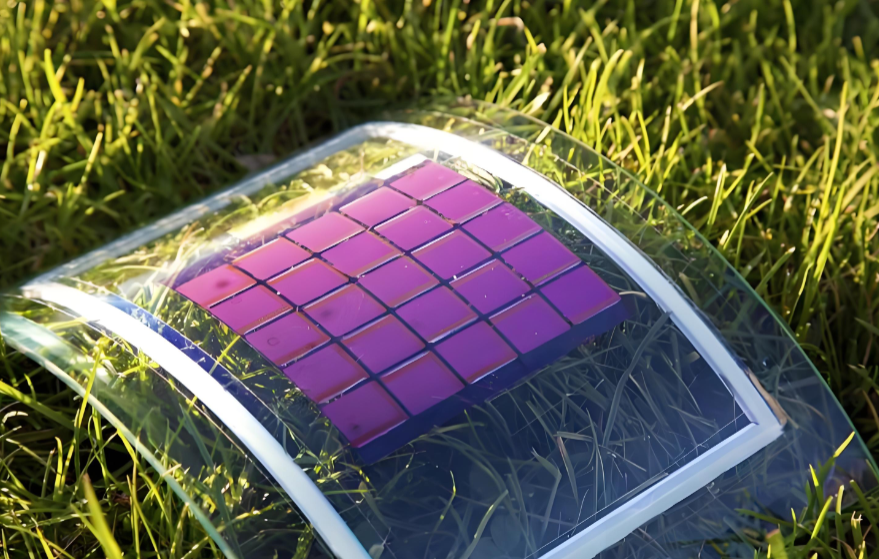

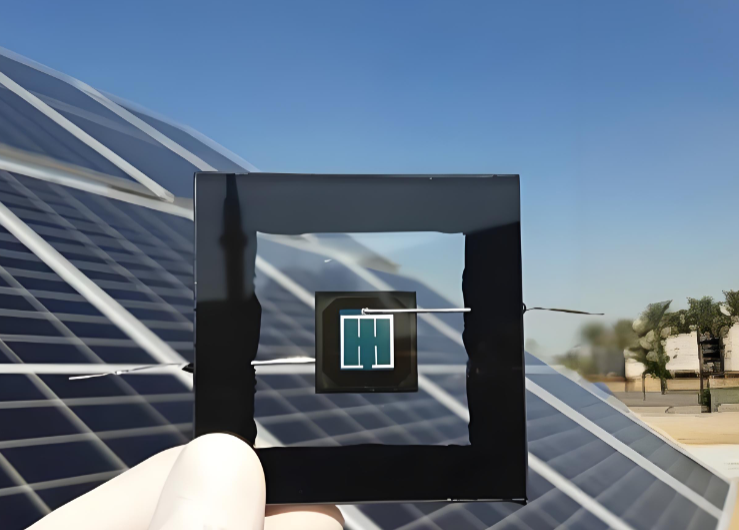

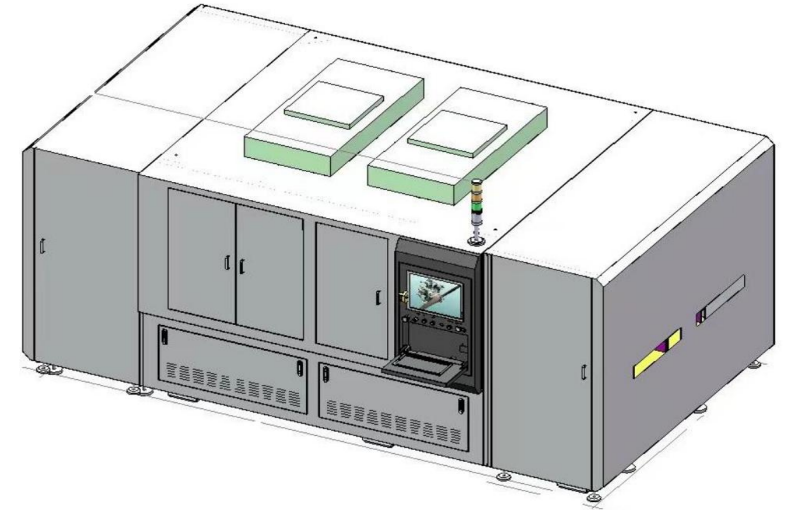

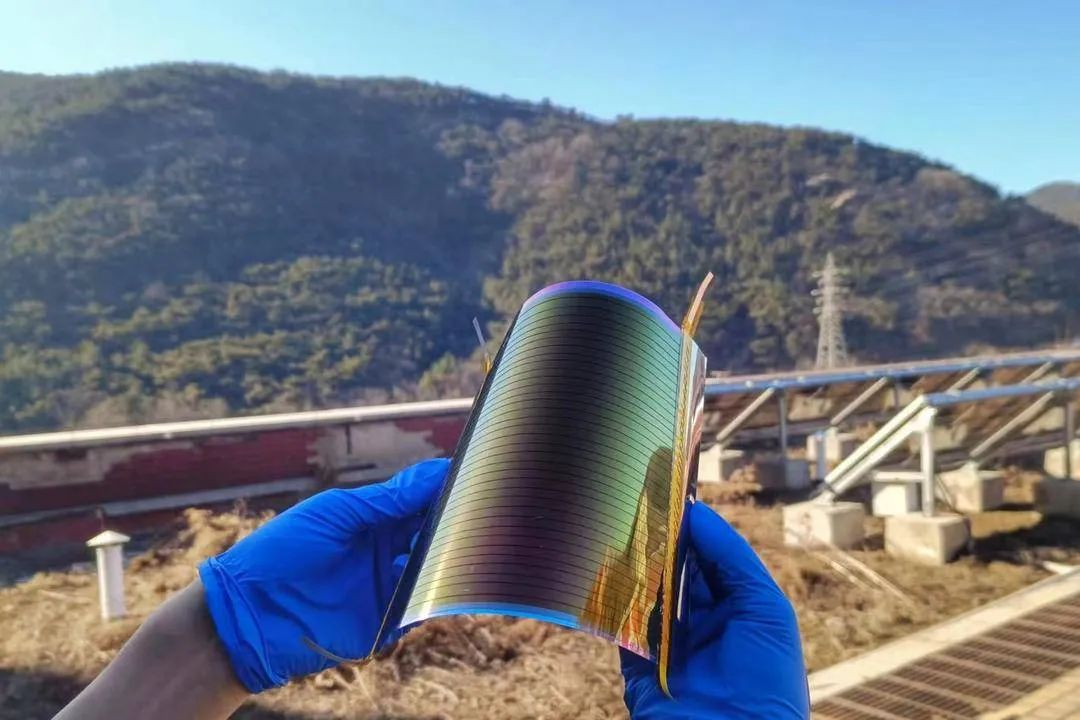

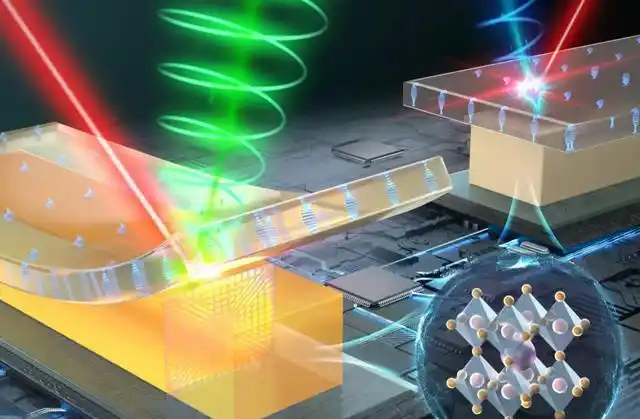

In the manufacturing of thin-film solar cells, such as perovskite cells, laser scribing (P1, P2, P3) and edge cleaning (P4) are critical processes that directly impact cell efficiency and production yield. Multi-beam synchronous processing technology stands as a pivotal innovation for enhancing manufacturing efficiency. LeCheng Intelligent, a leader in this field, achieves high-precision, high-throughput processing of large-area panels through advanced optical design, sophisticated motion control, and deep process integration.