LeCheng Intelligent's Multi-Beam Laser Synchronous Processing Technology

Introduction

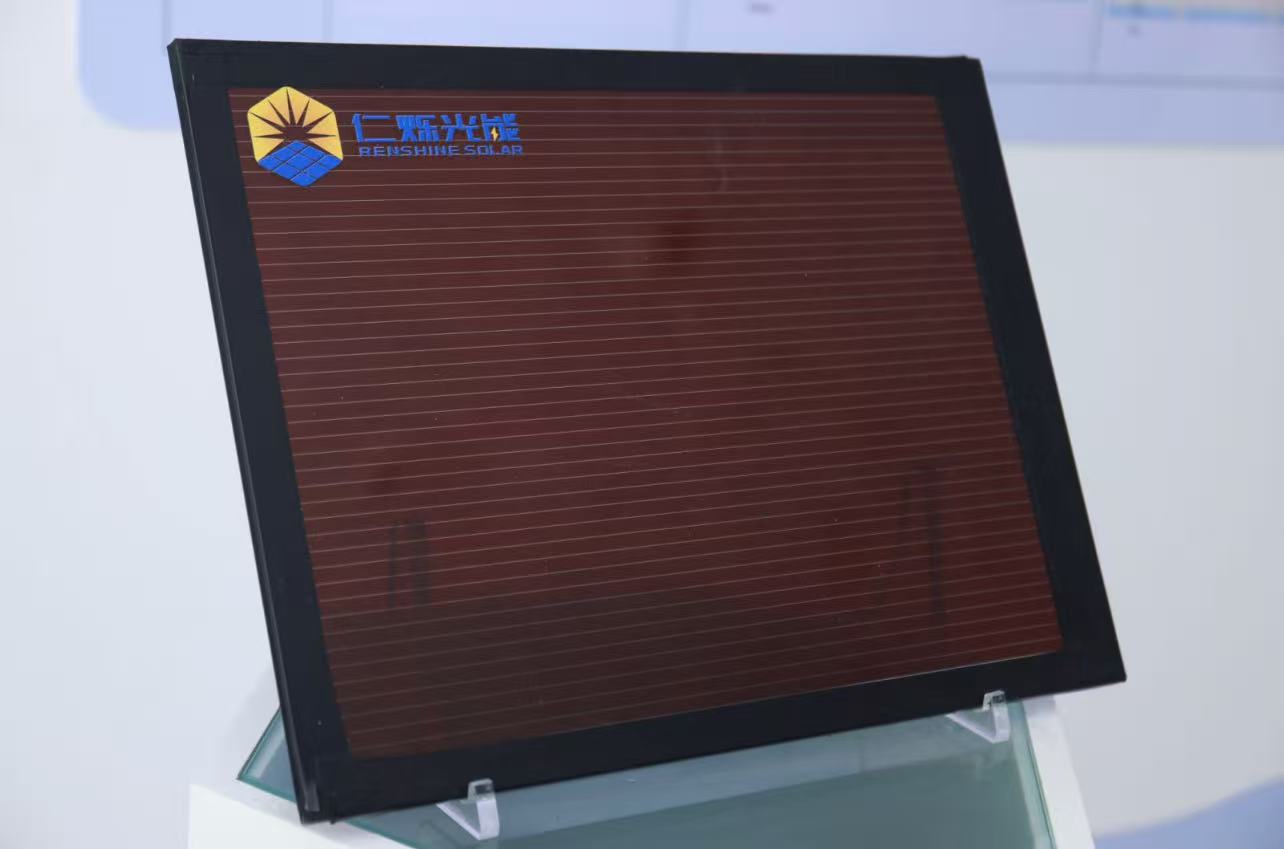

In the manufacturing of thin-film solar cells, such as perovskite cells, laser scribing (P1, P2, P3) and edge cleaning (P4) are critical processes that directly impact cell efficiency and production yield. Multi-beam synchronous processing technology stands as a pivotal innovation for enhancing manufacturing efficiency. LeCheng Intelligent, a leader in this field, achieves high-precision, high-throughput processing of large-area panels through advanced optical design, sophisticated motion control, and deep process integration.

Core Technology 1: Advanced Optical Beam Splitting

The foundation of multi-beam processing is the precise splitting of a single laser source into multiple, independently controllable beams of consistent quality.

High-Precision Beam Splitting:Utilizing both refractive and diffractive optical elements, LeCheng's technology can split a single high-power laser into up to 12 or even 24 synchronous beams. This dramatically increases processing speed while ensuring uniform energy distribution and spot quality for each beam, which is crucial for consistent scribe line geometry.

Spatial Beam Matching:Each split beam path is meticulously calibrated to ensure all beams focus accurately on the same processing plane. This eliminates path-to-path deviations in scribing line width or depth, guaranteeing uniformity across the entire panel.

Core Technology 2: High-Speed Precision Motion Control & Synchronization

Synchronizing multiple laser beams with the high-speed movement of large panels presents a significant challenge. LeCheng's expertise in automation provides robust solutions.

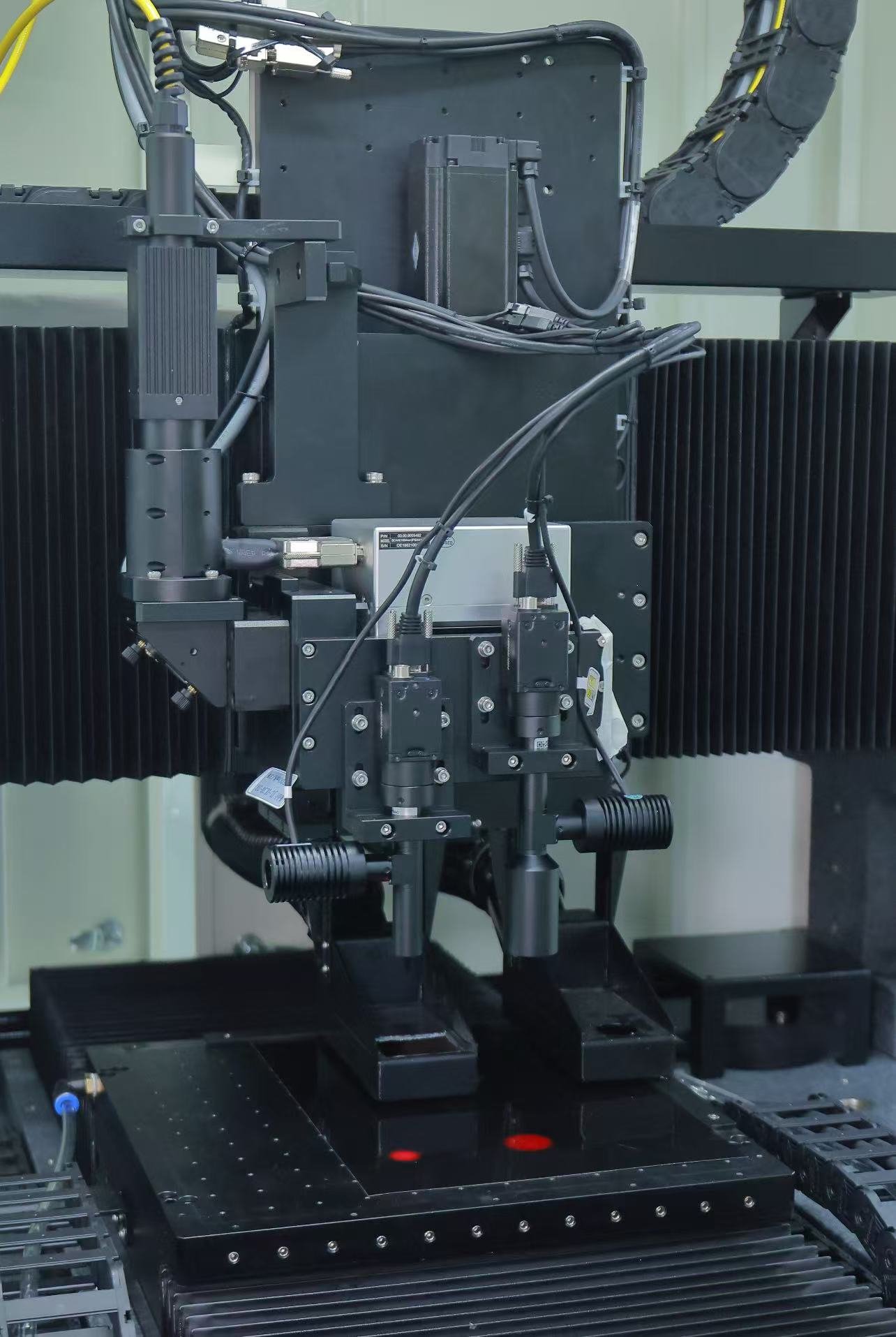

Real-Time Trajectory Tracking:Substrates like glass can warp, or initial P1 scribe lines may bend during earlier manufacturing stages. LeCheng's systems employ high-resolution vision systems to identify the actual position of the P1 line. The paths for P2 and P3 scribes are then automatically and dynamically adjusted to follow this trajectory. This minimizes the dead zone between cell strips, directly improving the module's overall conversion efficiency.

Dynamic Focus Following:For large-format panels (up to 2400mm x 1200mm), maintaining a consistent distance between the laser head and the often non-perfectly flat substrate is paramount. Integrated height sensors continuously monitor the glass surface. The control system dynamically adjusts the focal point in real-time, ensuring it remains precisely on the substrate surface throughout the entire travel. This guarantees consistent scribing depth and width from edge to edge.

Core Technology 3: Integrated Process Expertise

Advanced hardware is only part of the equation. LeCheng's deep process knowledge ensures the technology is applied effectively for optimal results.

Customized Laser Source Selection:LeCheng provides expert recommendations on the optimal laser type (e.g., nanosecond IR/green, picosecond UV) based on the specific requirements of each scribing step (P1/P2/P3) and the client's unique material stack, effectively balancing processing quality and operational cost.

High Process Compatibility:Their equipment and process parameters are highly adaptable to various customer material choices and production line layouts, offering significant flexibility.

Dual Incident Modes:The equipment can be configured for laser incidence from either the glass side or the film side, catering to diverse customer process requirements.

Conclusion

By seamlessly integrating advanced optical capabilities(precision beam splitting), superior automation control(real-time trajectory tracking and dynamic focus following), and deep process expertise, LeCheng Intelligent delivers high-efficiency, high-yield multi-beam laser synchronous processing solutions. This provides the perovskite solar industry and other thin-film battery sectors with reliable and advanced production tools, actively driving the industrialization of next-generation photovoltaic technologies.