40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

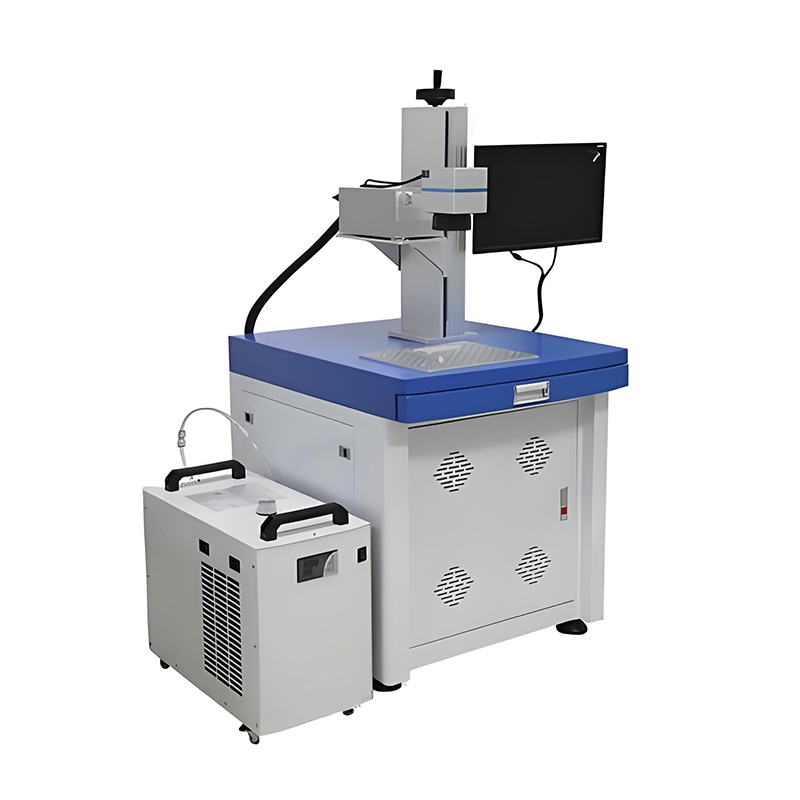

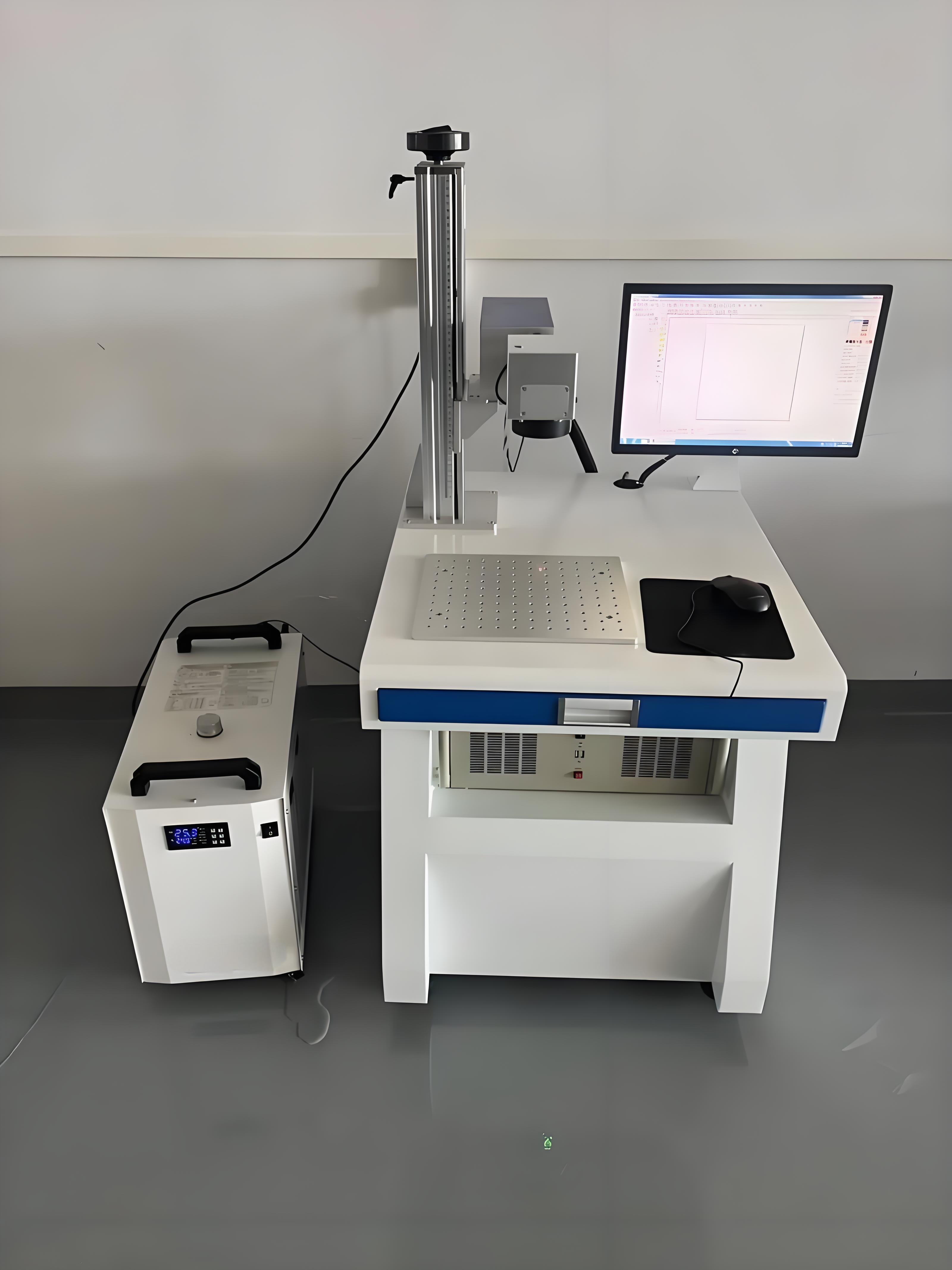

+86-17751173582The UV laser marking machine features an advanced 355nm wavelength laser source, delivering an exceptionally small focused spot size for ultra-fine processing. Its high-precision galvanometer system ensures stable and accurate beam control, while the compact and rigid structure minimizes vibration, enhancing marking consistency. The machine is equipped with a user-friendly control interface, supporting multiple file formats and programmable settings for seamless operation. Additionally, its air-cooled or water-cooled options provide flexibility for different industrial environments.

Minimal Heat-Affected Zone (HAZ): The UV laser’s cold-processing technology virtually eliminates thermal damage, making it ideal for heat-sensitive materials.

Ultra-Fine Marking Precision: With a spot size as small as 10-20μm, it achieves high-resolution engravings, even on micro-components.

High Speed & Efficiency: Offers 30% faster marking speeds compared to traditional lasers, boosting production throughput.

Long Service Life: The high-quality laser source and optical components ensure over 30,000 hours of operational durability.

Wide Material Compatibility: Works flawlessly on plastics, glass, ceramics, metals, and semiconductors without surface deformation.

Due to its non-contact, high-precision marking capability, this UV laser machine is widely used in industries requiring micro-scale engravings and permanent markings, including:

Electronics: PCB trace marking, IC chip coding, and SMD component labeling.

Medical Devices: Surgical tools, implants, and pharmaceutical packaging with FDA-compliant markings.

Jewelry & Precision Tools: Fine engraving on watches, rings, and cutting tools.

Automotive & Aerospace: Part serialization, QR codes, and anti-counterfeit markings.

Consumer Goods: Logo engraving on glass, ceramics, and premium plastics.

This UV laser marking system is the optimal solution for industries demanding high accuracy, durability, and clean processing—ensuring superior mark quality with zero material waste or thermal distortion.

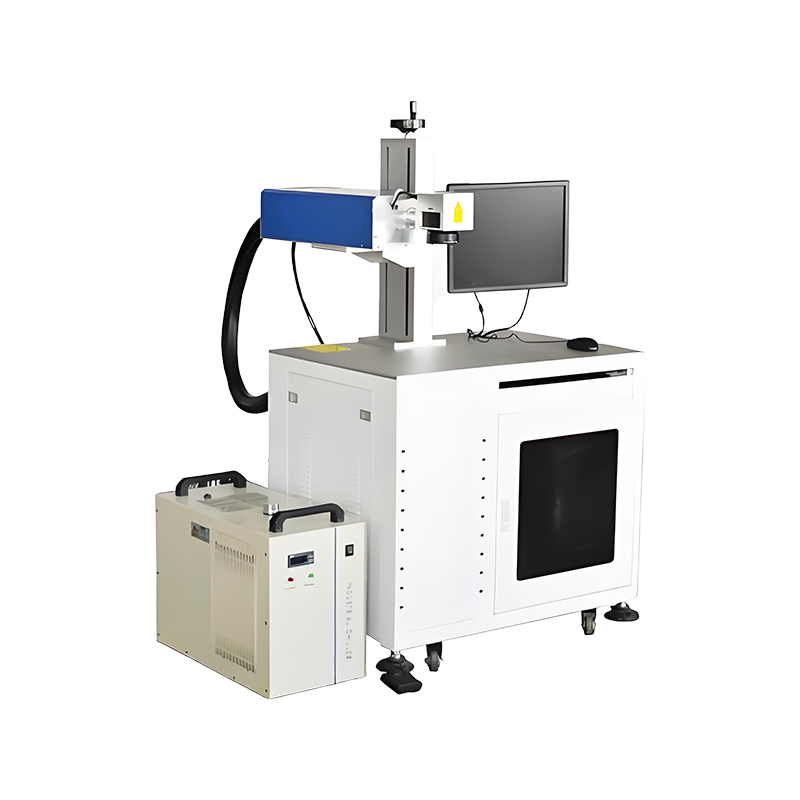

532nm green laser for ultra-fine, high-contrast marking. Ideal for sensitive materials with minimal heat impact. 30% faster speed than IR lasers, boosting productivity. Wide compatibility: plastics, metals, ceramics, glass.

More10.6μm Wavelength Expert——Vaporize coatings without material damage. 0.1mm Fine Marking on Plastics——Food-safe engraving for packaging & labels. 60W/100W RF-Sealed Tubes——30% longer lifespan vs glass tubes. Auto-Focus for 3D Objects——5s adjustment, ±0.2mm accuracy.

More20W/50W Fiber Laser Power——Permanent marks on metals & plastics. Auto-Focus for Curved Surfaces——10s tool-free setup, ±0.1mm accuracy. 100,000+ Hours Maintenance-Free——IP54 protection, air-cooled design.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582