40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

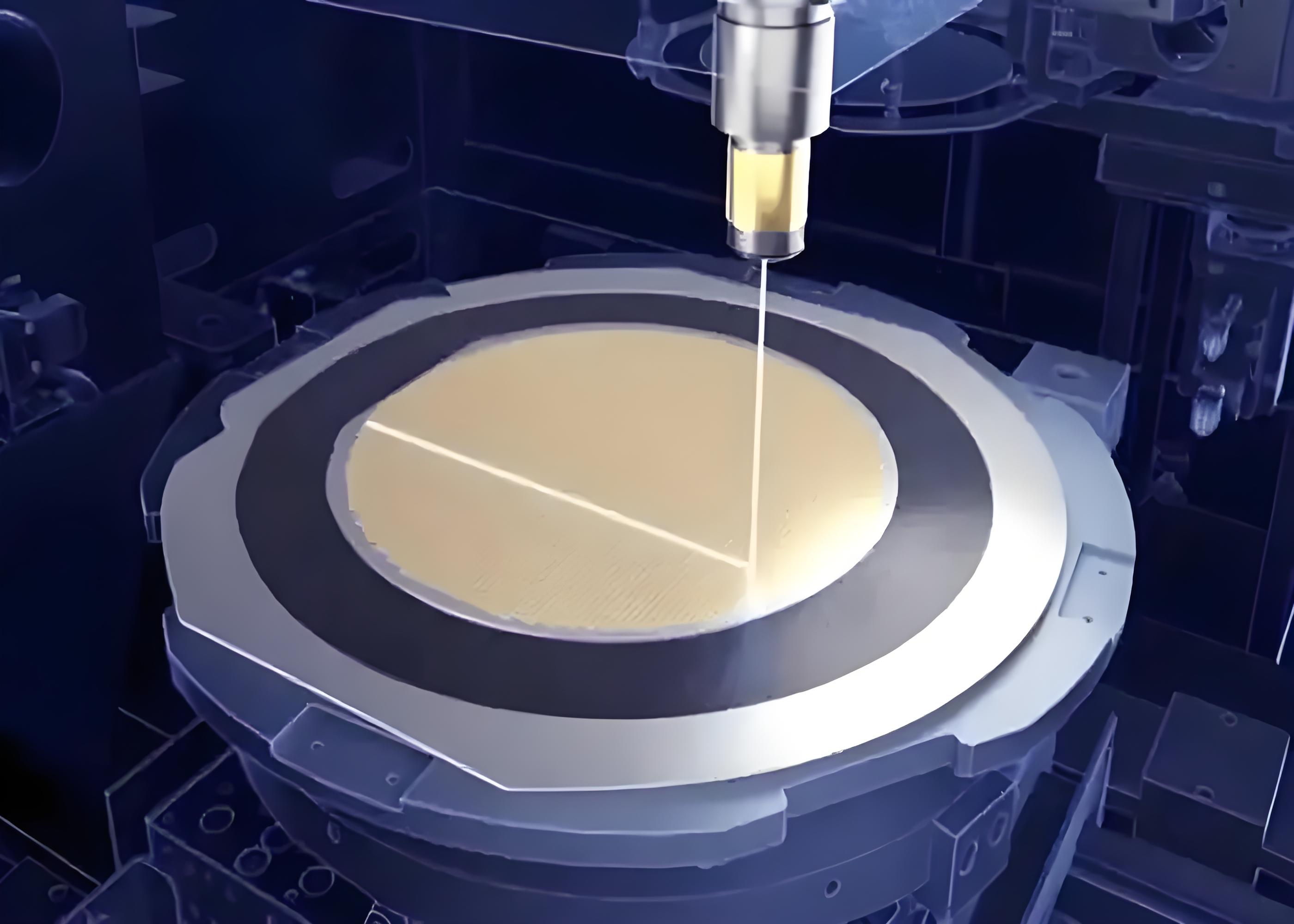

+86-17751173582High-Power Ultrafast Laser System: Utilizes picosecond/femtosecond pulsed lasers to minimize heat-affected zones (HAZ) and material damage.

Precision Motion Stage: Equipped with linear motor-driven systems, achieving ±1μm repeat positioning accuracy for stable and consistent cutting paths.

Adaptive Optical Focusing: Dynamically adjusts laser focal points to accommodate ingots of varying thicknesses, ensuring optimal cutting quality.

Real-Time Monitoring & Feedback: Integrated CCD vision alignment and laser ranging systems enable live process control with automatic parameter adjustment.

Modular Design: Supports multi-station configurations, compatible with 4-inch, 6-inch, and 8-inch ingots for enhanced flexibility.

Low Material Waste: Non-contact laser cutting achieves kerf widths of 20–50μm, improving material yield by over 30%.

High Throughput: 5–10× faster than diamond wire saws, reducing processing time to <2 hours per ingot.

Superior Surface Quality: Cut surface roughness (Ra) <0.5μm, minimizing post-polishing steps and costs.

Eco-Friendly: Eliminates cutting fluid pollution and reduces energy consumption by 40%, aligning with sustainable manufacturing.

SiC Power Devices: Ideal for wafer preparation of MOSFETs, SBDs, and other power electronics.

RF Components: Enables precise slicing for GaN-on-SiC wafers in 5G base stations and satellite communication systems.

New Energy Vehicles: Supports SiC wafer production for EV inverters, OBC modules, and other critical components.

Dual-chuck design enables non-stop material processing. Synchronous cutting/loading doubles production output. Precision servo control maintains ±0.08mm accuracy. Smart chuck synchronization eliminates material waste.

MoreP-Series delivers industry-leading 120m/min cutting speed. Six-axis CNC control enables complex 3D pipe profiles. Automatic loading/unloading boosts production efficiency. Maintains ±0.1mm precision across all pipe diameters.

MoreFive-axis robotic cutting for complex 3D metal parts. High-power fiber laser handles thick and thin materials. Precision ±0.05mm cutting for automotive components. Smart programming reduces material waste significantly.

MoreUltra-precise laser cutting for flexible OLED panels. Non-contact process prevents display layer damage. Automated alignment ensures micron-level cutting accuracy. Compact design fits cleanroom production environments.

MoreCold Laser Processing: Cuts glass without thermal cracks or chipping. Micron-Level Precision: Achieves clean edges with ≤20μm accuracy. Multi-Layer Capable: Processes laminated/tempered glass effortlessly. Industrial Reliability: 24/7 operation with minimal maintenance.

MoreVersatile Dual Function: Precision cutting AND engraving in one compact system. Non-Material Master: Perfectly processes wood, acrylic, leather, fabric, paper. User-Friendly Operation: Intuitive software & rapid setup for instant productivity. Industrial-Grade Results: Professional quality without industrial complexity.

MoreSpace-Saving Design: Compact benchtop unit fits any workshop or office. Precision Metal Cutting: Cuts steel, aluminum, copper with razor-sharp detail. Plug-&-Play Operation: User-friendly software, minimal training required. Industrial Performance: Professional results without industrial space needs.

MoreHigh-Power Fiber Laser: Delivers superior speed & cuts thick metals effortlessly. Exceptional Precision & Quality: Achieves clean, burr-free edges on intricate contours. Energy-Efficient & Cost-Effective: Low power consumption maximizes operational savings. Versatile & Reliable: Processes diverse metals (steel, aluminum, copper) with consistent results.

MoreUltrafine 5μm Laser Etching—Sub-micron precision for semiconductors & FPCs. 2000mm/s High-Speed Processing—4x faster vs chemical etching, zero waste. 200+ Material Compatibility—From glass to titanium alloys, non-contact. Intelligent HMI Control—Auto-focus & CAD integration, ISO certified.

MoreNanometer precision for flawless micro-scale machining. Ultrafast lasers enable clean, burr-free cuts. Multi-material compatibility for versatile applications. Automated focus control ensures consistent high quality.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582