40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582Application Field:

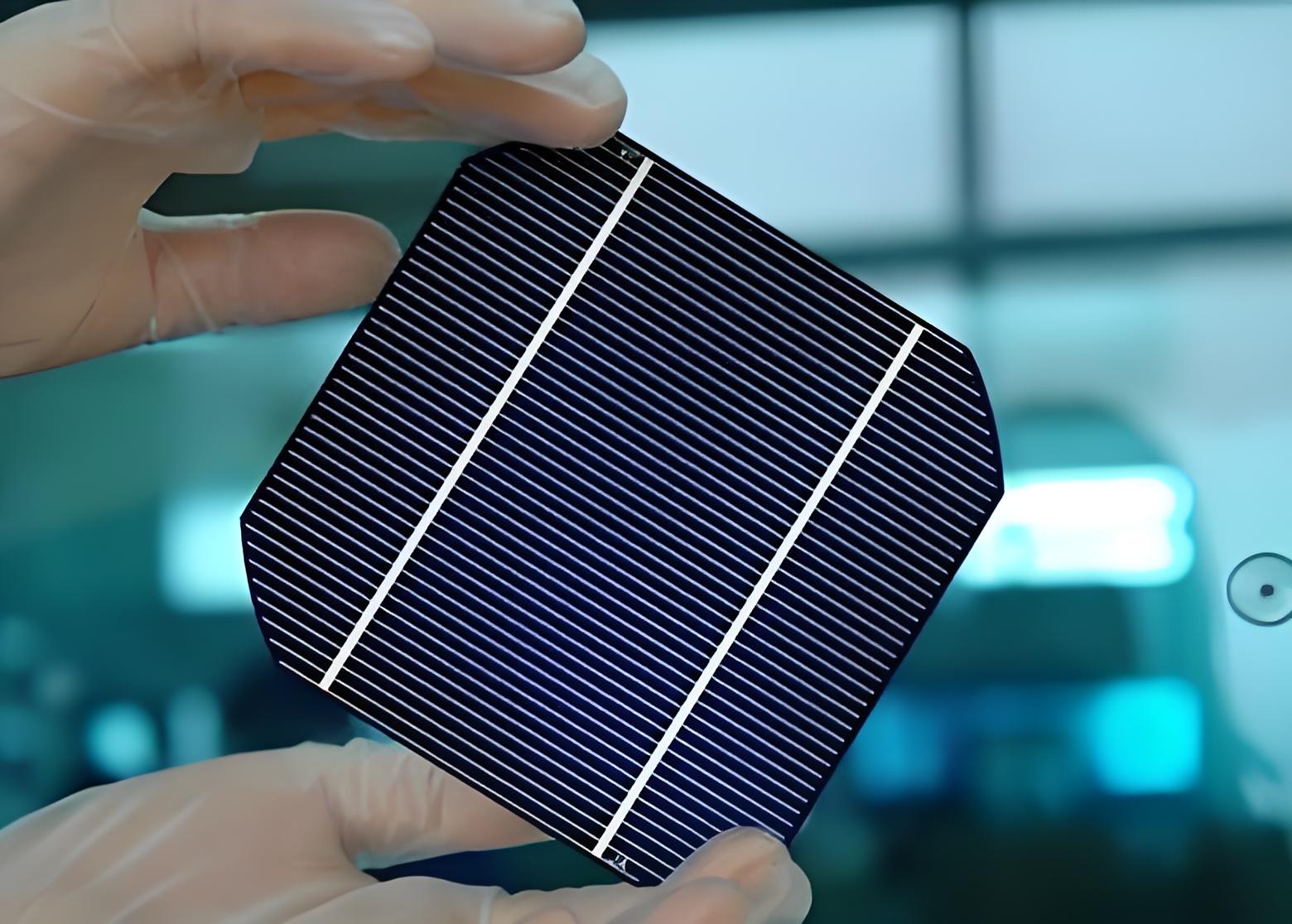

Laser edge cleaning for thin-film solar cells.

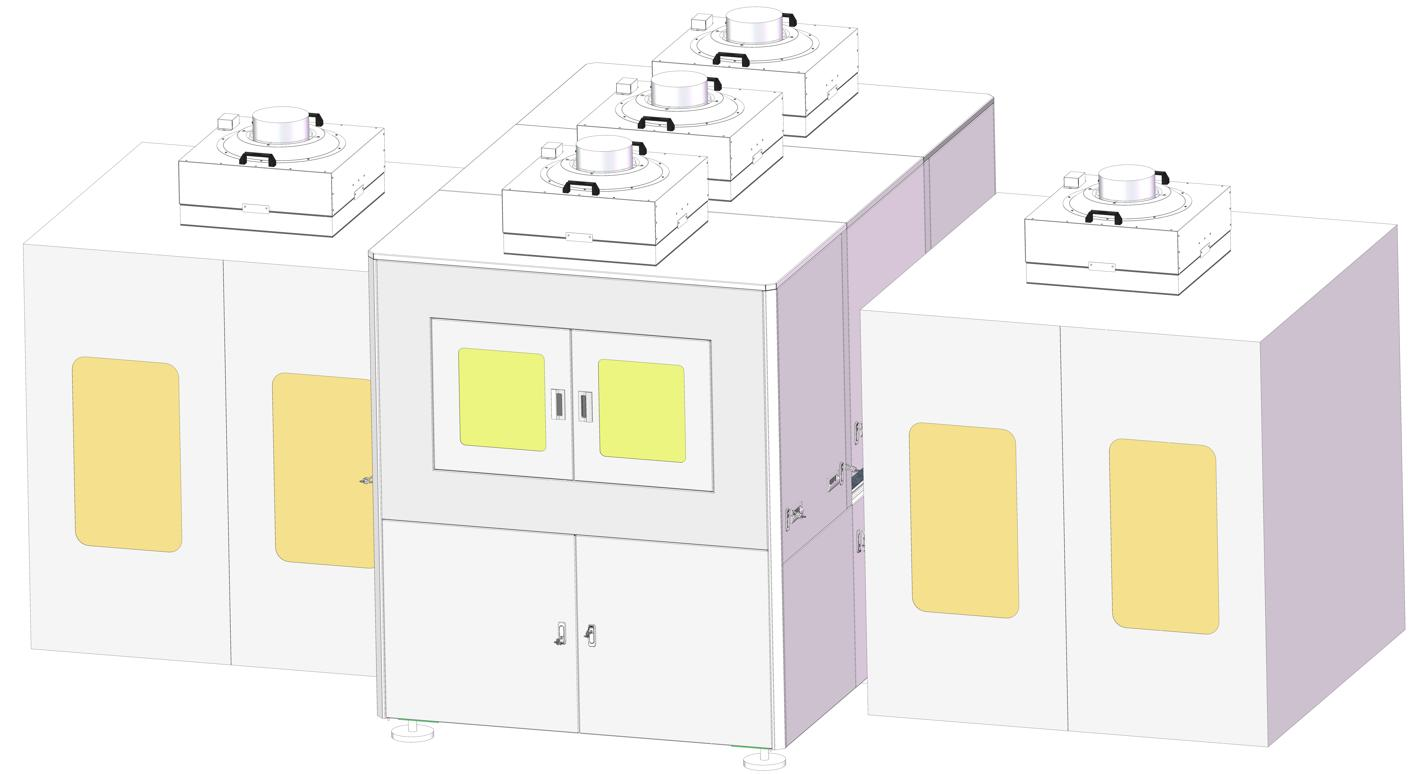

Structural Features:

Three-station design incorporating an unwinding mechanism, laser processing host, and rewinding mechanism

Edge-cleaning modules mounted on a fixed gantry structure, with irradiation from the upper coated surface

Optical system capable of simultaneous edge cleaning using multiple lasers and optical modules

Highly integrated automation control system, optical processing system, and imaging system for stable and reliable operation

Product Advantages:

Multiple independently controlled edge-cleaning axes and optical modules with flexible parameter settings – no mutual interference during simultaneous operation for high efficiency

Independent following-type dust collection port with excellent dust removal performance

Triple-vision edge detection and positioning system ensures higher edge-cleaning positional accuracy

Typical Applications:

In thin-film solar cell production, this equipment is used to remove excess materials or coatings from cell edges, significantly improving cell performance and quality. For instance:

Mass Production Lines: Enables rapid, high-efficiency edge cleaning in large-scale manufacturing facilities by leveraging its multi-axis/multi-module simultaneous operation capability

Precision Processing: The triple-vision positioning system ensures micron-level accuracy for critical edge treatment processes

Flexible Manufacturing: Adaptable to various thin-film solar cell designs (e.g., CIGS, CdTe) with customizable parameter settings for different coating materials

Clean Production: Integrated dust collection system maintains clean processing environments while meeting industrial emission standards

The equipment particularly excels in:

High-throughput production environments requiring >95% edge-cleaning consistency

Next-generation solar cells demanding <50μm edge treatment precision

Automated lines where seamless integration with upstream/downstream processes is crucial

Ultrafast laser scribing enhances solar cell production efficiency. Non-contact processing prevents silicon wafer micro-cracks. Automated alignment ensures ±5μm precision for all cell types.

MoreHigh-efficiency thin-film solar production with precision automation. Modular design for flexible, scalable manufacturing solutions. Advanced coating tech ensures uniform, durable solar layers. Energy-saving systems reduce operational costs significantly.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582