40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582The LC-LED-AAA-300S LED Solar Simulator is a high-precision photovoltaic testing system developed by Lecheng Intelligent, specifically optimized for perovskite solar cell and module characterization. Unlike conventional LED simulators that rely on direct LED emission, the LC-LED-AAA-300S integrates a complete optical shaping system, delivering highly collimated, uniform, and spectrally accurate sunlight simulation.

The system complies with IEC 60904-9 Edition 3 international standards and achieves an overall A+ rating across spectral match, irradiance uniformity, and temporal stability. With a wide spectral coverage from 350 nm to 1200 nm, it precisely matches the full-band absorption characteristics of perovskite photovoltaic materials, from ultraviolet to near-infrared.

Designed for both laboratory research and pilot-line verification, the LC-LED-AAA-300S supports steady-state long-duration testing (24–1000 h) as well as transient pulse testing (>200 ms), making it an ideal platform for efficiency calibration, device tolerance evaluation, and long-term stability studies of perovskite solar devices.

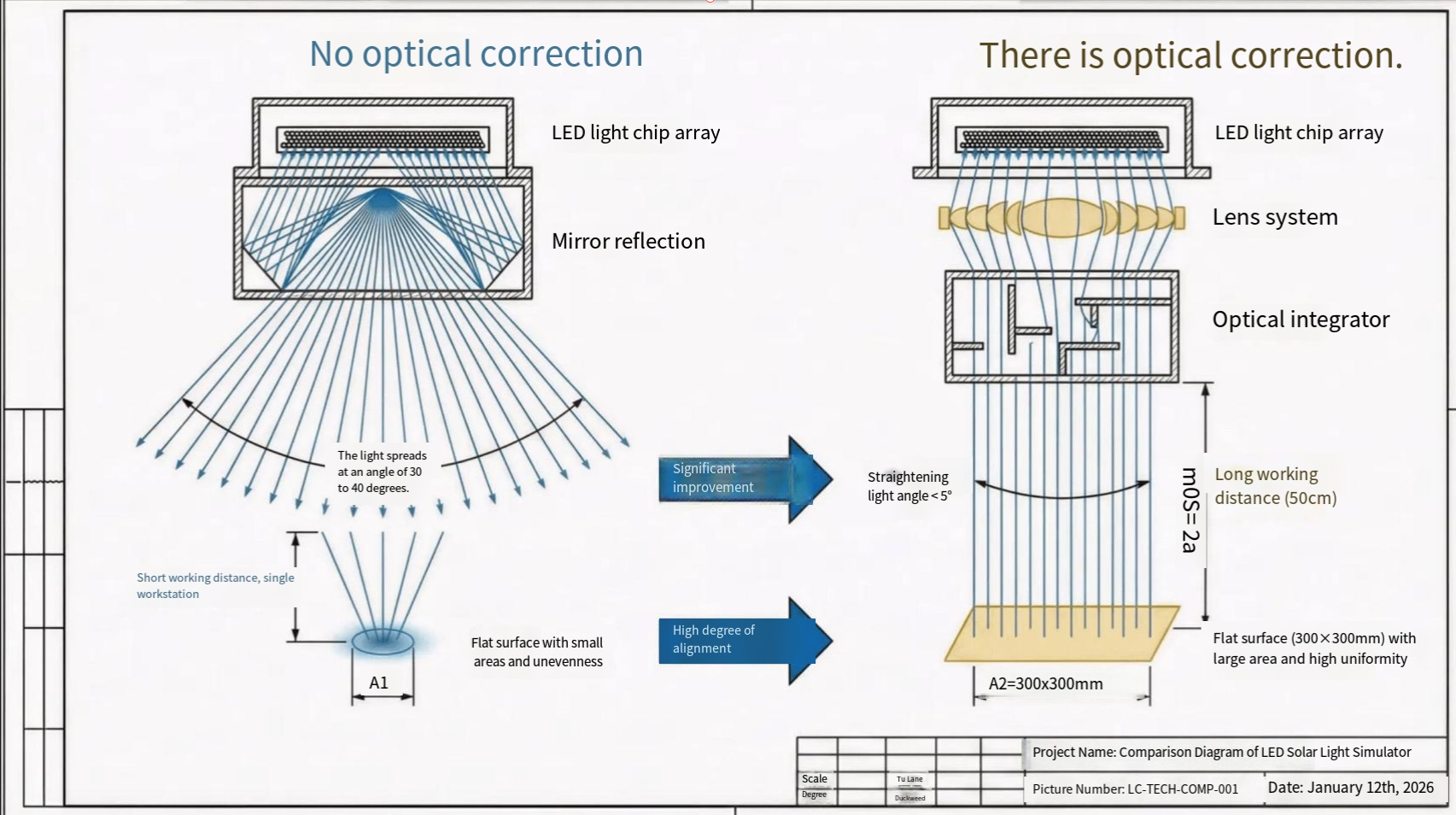

Unlike many competing LED solar simulators that emit divergent light, LC-LED-AAA-300S employs a lens + optical integrator architecture, forming near-parallel sunlight.

Optical Performance Comparison

| Indicator | Conventional LED Simulator | LC-LED-AAA-300S |

|---|---|---|

| Collimation Angle | 30–40° (divergent) | < 5° (collimated) |

| Working Distance | Short | 50 cm |

| Uniform Area | Small / Non-uniform | 300 × 300 mm |

| Light Quality | Inconsistent | True parallel sunlight |

This optical design significantly improves measurement accuracy for large-area perovskite devices and modules.

The system has been tested by third-party international laboratories, with all key indicators meeting or exceeding IEC 60904-9-2020 requirements.

Overall Performance Rating

| Parameter | Grade |

|---|---|

| Spectral Match | A+ |

| Irradiance Uniformity | A |

| Temporal Stability | A+ |

| Overall Rating | A+ |

Temporal Stability Details

| Mode | Performance |

|---|---|

| Short-Term Stability | ≤ 0.25% |

| Long-Term Stability | ≤ 1% |

| Continuous Operation | 24–1000 h |

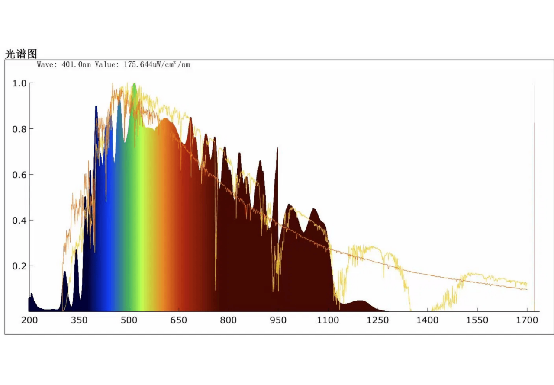

LC-LED-AAA-300S is specifically designed to match the spectral sensitivity of perovskite materials.

Spectral Band Accuracy

| Wavelength Band (nm) | Measured Ratio | Grade |

|---|---|---|

| 300–470 (UV-Blue) | 1.0030 | A+ |

| 470–561 (Blue-Green) | 1.0241 | A+ |

| 561–657 (Green-Yellow) | 1.0311 | A+ |

| 657–772 (Red) | 1.0375 | A+ |

| 772–919 (Near-IR) | 0.9783 | A+ |

| 919–1200 (Near-IR) | 0.9261 | A+ |

This ensures accurate spectral response evaluation and eliminates wavelength-induced testing errors.

The simulator supports a wide irradiance range and dual operating modes to cover multiple R&D scenarios.

Irradiance Control

| Parameter | Specification |

|---|---|

| Irradiance Range | 0.3 – 1.2 Sun |

| Power Density | 300 – 1200 W/m² |

| Adjustment | Continuous |

Test Modes

| Mode | Application |

|---|---|

| Transient Pulse (>200 ms) | Rapid I-V testing, reduced heating |

| Steady-State Continuous (24–1000 h) | Aging & long-term stability |

True Parallel Sunlight: Optical shaping ensures realistic illumination conditions

Large Uniform Area: 300 × 300 mm Class-A uniformity for module-level testing

Perovskite-Focused Design: Spectral accuracy tailored for next-generation PV

Wide Dynamic Range: 0.3–1.2 sun supports low-light and stress testing

Industrial Reliability: 10,000+ hour LED lifetime with water-cooling system

Turnkey Solution: Integrated power, cooling, optics, and control systems

The LC-LED-AAA-300S LED Solar Simulator is widely used in:

Perovskite solar cell efficiency calibration

Perovskite module and mini-module testing

Laser-scribed perovskite device characterization

Long-term light soaking and aging experiments

Device tolerance and stress testing

R&D laboratories and pilot production lines

Universities and photovoltaic research institutes

| Item | Specification |

|---|---|

| Model | LC-LED-AAA-300S |

| Spectral Standard | IEC 60904-9 Edition 3 |

| Spectral Grade | A+ |

| Uniform Area | 300 × 300 mm |

| Collimation Angle | < 5° |

| Working Distance | 50 cm |

| Irradiance Range | 300–1200 W/m² |

| Sun Intensity | 0.3–1.2 Sun |

| Stability | ≤0.25% (short) / ≤1% (long) |

| Light Source Lifetime | ≥10,000 h |

| Cooling | Industrial water cooling |

| Recommended Environment | ≤25°C, controlled humidity |

Multi-channel design enables parallel IV and MPPT testing. 3A LED simulator ensures stable AM1.5G illumination. Independent 25–100°C control keeps each module stable. Supports 50×50 to 300×300 mm modules for flexible testing.

MoreLED simulator delivers precise AM1.5G output with stable irradiance. Adjustable intensity ensures flexible testing for PV materials. Real-time LED temperature control maintains consistent light quality. Clean interface enables easy spectral and irradiance adjustments.

More1. Integrated AM0 light, thermal stage, and testing system in one cabinet. 2. Class A AM0 spectrum with extreme temperature simulation from -180°C to +150°C. 3. Multi-channel IV and MPPT testing enables high-throughput space PV evaluation. 4. Automated software supports 24/7 unattended stability and aging tests.

More1. Multi-channel architecture enables parallel IV and MPPT testing. 2. Independent channel control ensures high-precision data acquisition. 3. Built-in MPPT algorithms handle perovskite hysteresis effectively. 4. Automated software supports long-term, unattended stability testing.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582