40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582Overview

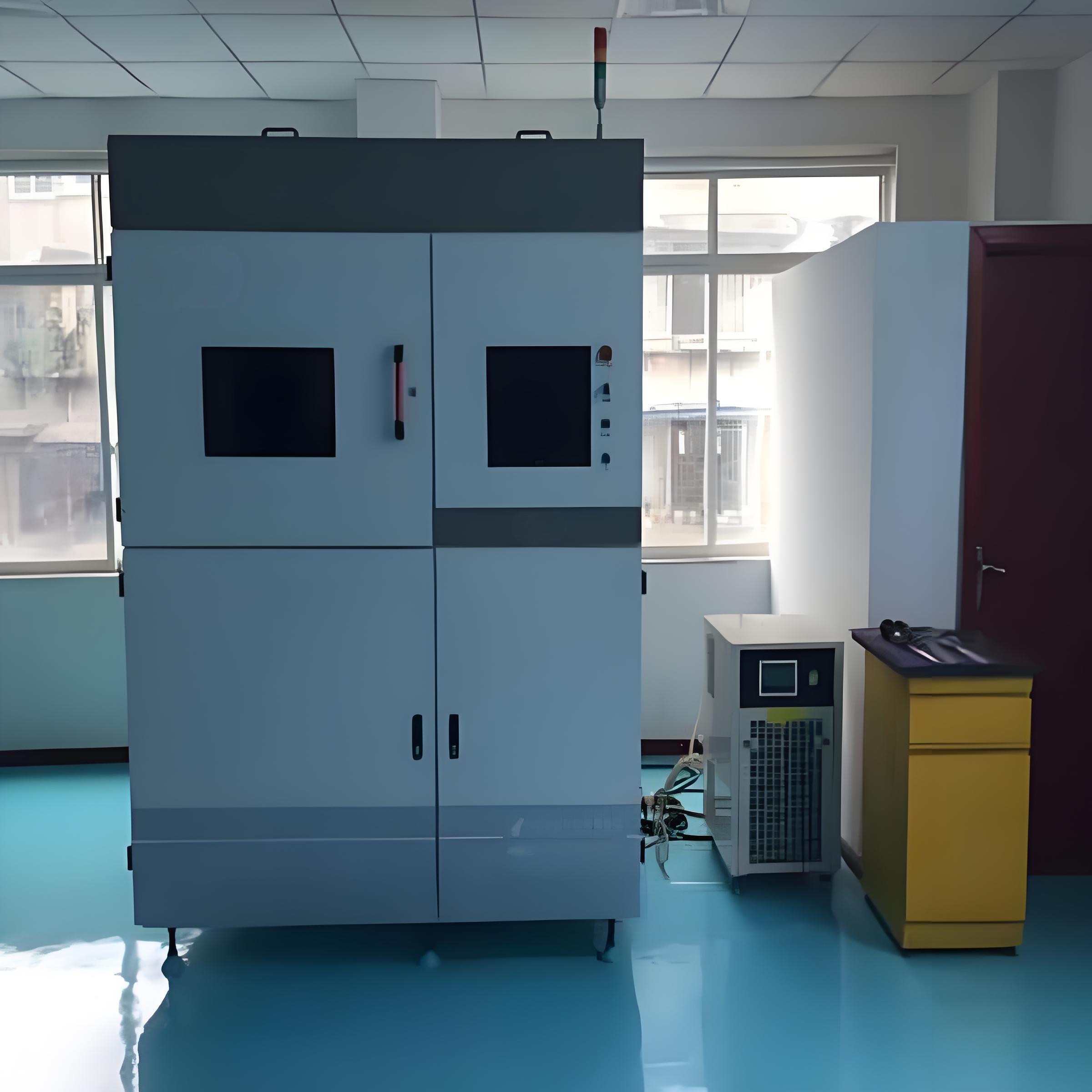

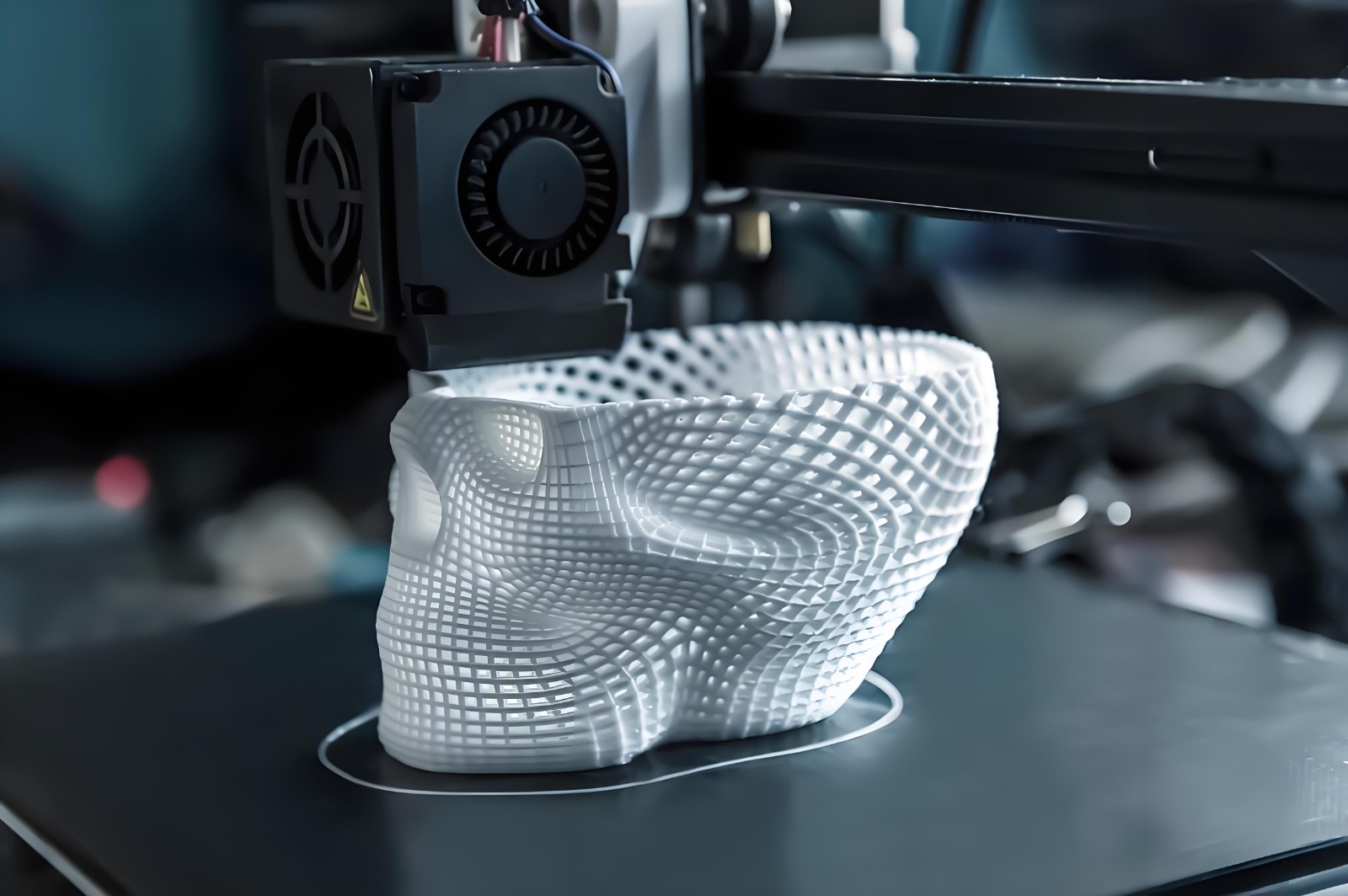

This industrial laser metal 3D printer utilizes Selective Laser Melting (SLM) technology with high-power fiber lasers to fuse metal powders layer-by-layer, enabling mold-free production of complex components. Ideal for aerospace, medical, and automotive applications, it supports stainless steel, titanium, aluminum alloys, and superalloys.

Laser System

500-1000W fiber laser (1070nm wavelength)

Adjustable spot size (70-150μm)

Multi-laser overlap option

Building System

Max. build volume: 300×300×400mm

Powder spreading accuracy: ±20μm

Oxygen control: <100ppm

Control System

Real-time melt pool monitoring

Bidirectional recoater technology

Multi-axis collision avoidance

Safety System

Inert gas recycling filtration

Automatic powder recovery

Class 1 laser safety

Parameter | Value | Industry Impact |

|---|---|---|

Surface Roughness | Ra 6-12μm (as-built) | 40%+ post-processing reduction |

Density | >99.5% | Meets aerospace standards |

Support Optimization | 70% less material | 35% cost saving |

Thermal Control | 300℃±5℃ preheating | 80% lower part distortion |

Advantages:

[Precision] ★★★★★

[Speed] ★★★★☆

[Build Size] ★★★★☆

[Cost Efficiency] ★★★★☆

Aerospace: Turbine blades, fuel nozzles

Medical: Patient-specific implants

Automotive: Lightweight transmission gears

Tooling: Conformal cooling inserts

Simultaneous 5-axis control enables complex 3D part machining. Integrated rotary table processes large curved surfaces. Smart collision avoidance ensures uninterrupted production.

MoreUltra-precise laser annealing for advanced chip manufacturing. Uniform energy distribution ensures consistent wafer treatment. Non-contact process prevents semiconductor surface damage. Automated calibration adapts to various wafer specifications.

MoreEco-friendly laser cleaning replaces chemical treatments. Precision cleaning without damaging base materials. Lightweight design enables easy operation anywhere. Low maintenance with long-lasting fiber laser source.

MorePrecision welding for high-efficiency EV battery production. Fully automated system boosts speed and reduces defects. Robust design ensures stable, long-term manufacturing performance. Customizable solutions for various battery types and sizes.

MoreHigh-precision laser cladding for durable metal repairs. Eco-friendly process reduces waste and energy consumption. Automated controls ensure consistent, high-quality coatings. Trusted by global industries for precision and reliability.

MoreUltra-precise laser transfer for Micro LED arrays. High-speed mass production with micron accuracy. Non-contact process ensures zero damage. Modular design for flexible production scaling.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582