40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582LC-SPV-ST-2525 Space PV Module Stability Test System is a turnkey laboratory solution that brings the critical elements of outer-space photovoltaic testing into one compact, highly integrated cabinet: Class A AM0 LED solar simulation, an ultra-wide temperature precision thermal stage, multi-channel electrical measurement, and intelligent automation software. It is designed for advanced space PV technologies such as GaInP₂/GaAs/Ge triple-junction cells and perovskite/silicon tandem cells, supporting device screening, long-term stability evaluation, and qualification-style verification.

Traditional space PV test benches often suffer from scattered instruments, complex cabling, unstable interfaces, and time-consuming setup. LC-SPV-ST-2525 addresses these pain points through a plug-and-play cabinet architecture, improving test repeatability and lab efficiency, while reducing wiring errors and daily maintenance workload.

To simulate the “space environment” in the most essential dimensions, the system combines:

AM0 spectral fidelity (for extraterrestrial irradiance conditions)

Extreme thermal cycling capability (for eclipse / sunlight transition conditions)

High-precision electrical characterization (for I-V / MPPT and degradation tracking)

Automation & data integrity (for long-duration and unattended experiments)

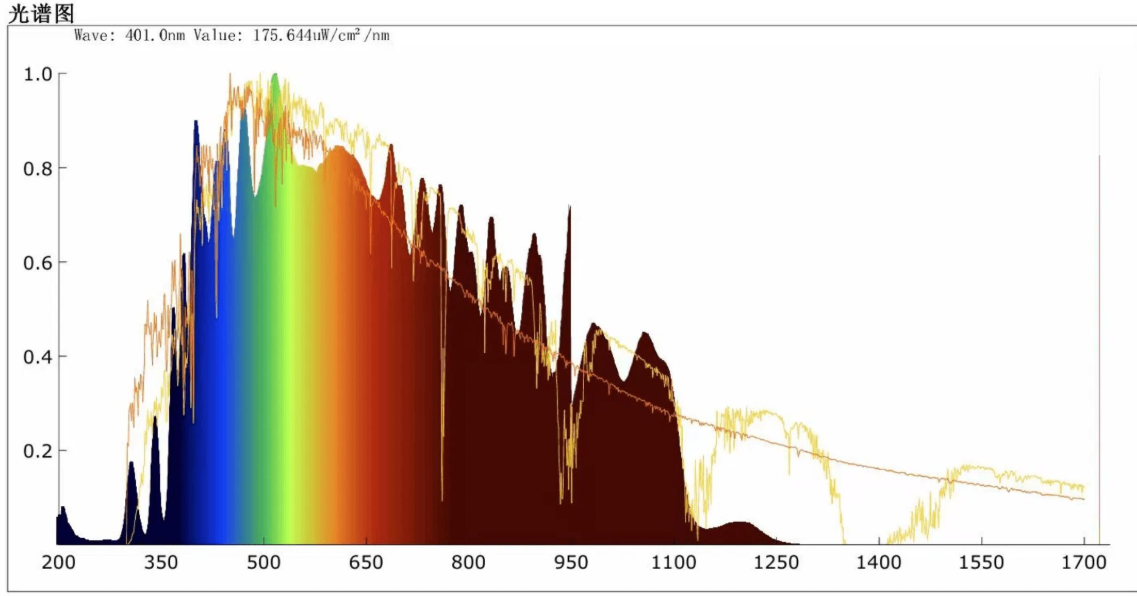

The integrated AM0 LED solar simulator provides Class A performance across spectral match, uniformity, and long-term stability, enabling accurate extraterrestrial PV characterization and aging studies.

AM0 Light Source Performance

| Item | Specification |

|---|---|

| Standard / Spectrum | IEC 60904-9 Edition 3 (AM0) |

| Spectral Match | Class A (350–1800 nm) |

| Irradiance Uniformity | ≤ ±2% (Class A) |

| Long-Term Instability | ≤ ±2% (Class A) |

| Standard Irradiance | 1367 W/m² (1 Solar Constant) |

| Irradiance Adjustment | 100–1500 W/m² (Continuous) |

| Lifetime | > 10,000 hours |

This allows users to perform AM0 efficiency validation, light soaking, and performance drift studies with controlled, repeatable exposure.

The precision photoelectric thermal stage supports extreme temperature simulation comparable to space thermal cycling conditions. Fast ramp rates help shorten test cycles, while high control precision supports reliable parameter comparisons.

Thermal Stage Capability

| Item | Specification |

|---|---|

| Temperature Range | -180°C to +150°C |

| Control Accuracy (Setpoint) | ±0.1°C |

| Temperature Stability | ±0.5°C (Long-term hold) |

| Ramp Rate | ≥ 15°C/min |

| Electrical Probing | 4 Kelvin probes, independently adjustable |

| Observation Window | Sapphire window + heated anti-fog |

| Vacuum Compatibility | 1×10⁻³ Pa (optional vacuum chamber) |

This module enables low-temperature performance mapping, thermal stress screening, and temperature-dependent degradation evaluation for space PV devices.

To increase throughput, the system supports 1–9 independent channels for parallel measurements. Each channel can run I-V scans and MPPT tracking, allowing fast comparison of multiple devices, recipes, or process conditions.

Electrical Measurement (Per Channel)

| Item | Specification |

|---|---|

| Voltage Range | 0 to ±60 V |

| Current Range | 0 to ±5 A |

| Accuracy | ≤ 0.1% F.S. |

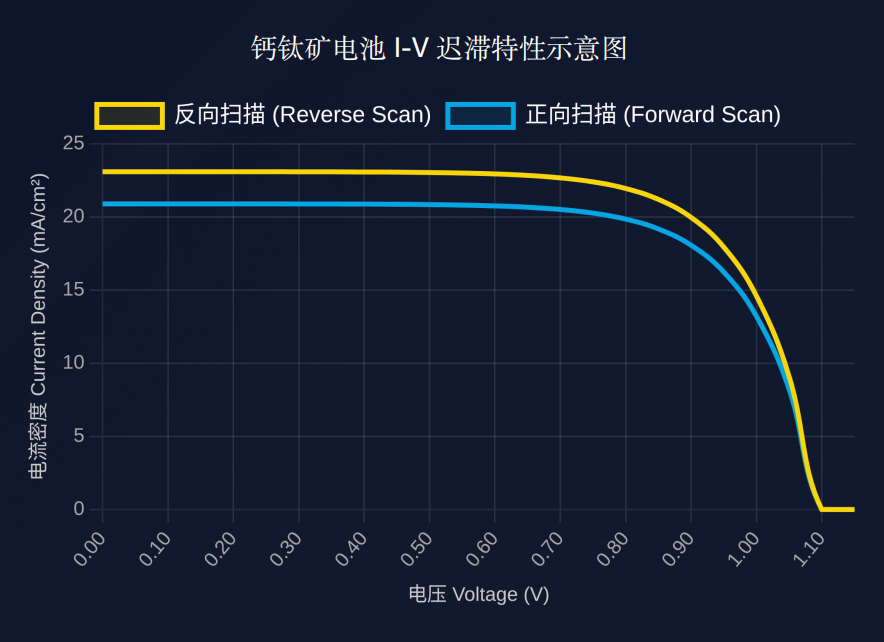

| Scan Types | Forward / Reverse / Loop (Hysteresis) |

| MPPT Algorithms | P&O, Incremental Conductance |

For perovskite and tandem devices, hysteresis loop scans help quantify instability effects related to ion migration or transient response, while MPPT tracking records realistic maximum-power behavior over time.

The system integrates an industrial PC and a high-definition display for stable long-term operation, remote control, and visualized data tracking. Automated sequence control supports 24/7 unattended tests with consistent execution and traceable data logs.

Automation & Software Functions

| Module | What It Does |

|---|---|

| Sequence Automation | Edit complex test workflows; unattended 7×24 |

| Real-Time Visualization | I-V, P-V, MPPT trajectories in real time |

| Report Output | One-click professional test reports |

| Data Management | Local large storage + network backup |

| Safety Protection | Over-temp / over-current / leakage protection |

| Emergency Stop | Physical emergency power cut-off |

This enables long-duration stability studies (light soaking + thermal cycling) with reduced manual intervention and improved data integrity.

One cabinet integrates light, thermal, measurement, and control.

Reduces scattered instruments and complex wiring.

Compact footprint improves lab space efficiency and professional appearance.

Class A AM0 spectrum for extraterrestrial irradiance.

-180°C to +150°C for extreme thermal environments.

Supports qualification-oriented evaluation and degradation mechanism studies.

1–9 channels configurable for throughput needs.

Optional modules: vacuum chamber and liquid nitrogen system to extend test capability for deeper space simulation scenarios.

Physical / Electrical / Environmental

| Category | Specification |

|---|---|

| Main Cabinet Size | 650 (W) × 550 (D) × 900 (H) mm |

| With Workbench | 1250 (W) × 550 (D) × 900 (H) mm |

| Total Weight | ~180 kg |

| Power Requirement | AC 220V ±10%, 50Hz, single-phase 3-wire |

| Power Consumption | ≤4.5 kW peak / ~2.5 kW typical |

| Operating Environment | 18–28°C, ≤60% RH |

Standards

| Standard Type | Standard |

|---|---|

| International | IEC 60904-9 (Edition 3, AM0 & AM1.5G) |

| North America | ASTM E927 |

LC-SPV-ST-2525 is suitable for aerospace manufacturers, universities, and research institutes, covering the full workflow from R&D to certification-style verification:

Material Screening & R&D: parallel high-throughput tests for perovskite/OPV and advanced space PV materials

Long-Term Stability Evaluation: light soaking under AM0 and extreme thermal cycling from -180°C to +150°C; MPPT power degradation tracking

Quality Certification & Final Validation: IEC/ASTM-aligned reports; traceable data for shipment validation and qualification readiness

Supported technologies: III-V multi-junction, perovskite/silicon tandem, flexible thin-film PV

| Item | LC-SPV-ST-2525 |

|---|---|

| AM0 Simulator | Class A, 350–1800 nm |

| AM0 Uniformity / Stability | ≤±2% / ≤±2% |

| Irradiance | 1367 W/m² standard; 100–1500 W/m² adjustable |

| Thermal Stage | -180°C to +150°C |

| Temp Accuracy / Stability | ±0.1°C / ±0.5°C |

| Ramp Rate | ≥15°C/min |

| Channels | 1–9 independent, customizable |

| I-V & MPPT | Hysteresis scan + P&O / IncCond MPPT |

| Electrical Range | 0…±60 V, 0…±5 A, ≤0.1% F.S. |

| Vacuum Option | 1×10⁻³ Pa compatible (optional chamber) |

| Power | AC 220V, ≤4.5 kW peak |

| Compliance | IEC 60904-9, ASTM E927 |

Multi-channel design enables parallel IV and MPPT testing. 3A LED simulator ensures stable AM1.5G illumination. Independent 25–100°C control keeps each module stable. Supports 50×50 to 300×300 mm modules for flexible testing.

MoreLED simulator delivers precise AM1.5G output with stable irradiance. Adjustable intensity ensures flexible testing for PV materials. Real-time LED temperature control maintains consistent light quality. Clean interface enables easy spectral and irradiance adjustments.

More1. Optical shaping delivers true parallel light with <5° collimation. 2. Class A+ spectrum ensures accurate perovskite response testing. 3. Large 300×300 mm uniform area supports device and module research. 4. Dual steady and pulse modes enable efficiency and stability tests.

More1. Multi-channel architecture enables parallel IV and MPPT testing. 2. Independent channel control ensures high-precision data acquisition. 3. Built-in MPPT algorithms handle perovskite hysteresis effectively. 4. Automated software supports long-term, unattended stability testing.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582