40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

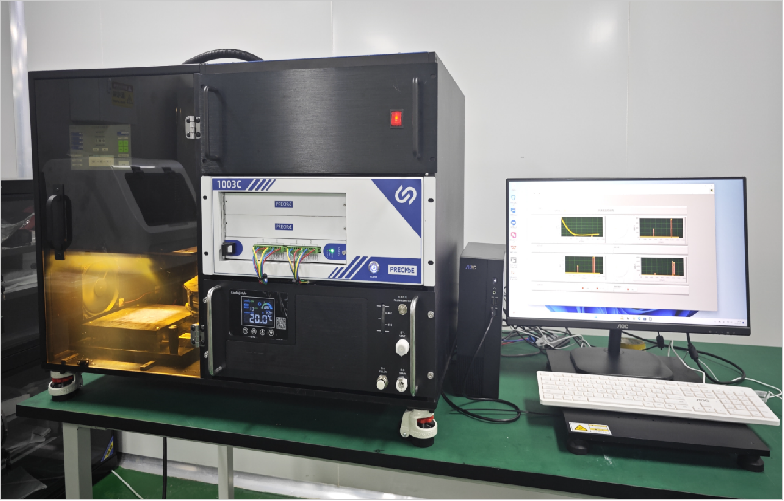

+86-17751173582The Multi-channel PV Module IV+MPPT Steady-State Test System is a high-precision testing platform developed by Lecheng Intelligent for advanced photovoltaic research and reliability evaluation. The system is specifically designed for perovskite, tandem, and thin-film photovoltaic devices, supporting comprehensive testing from small-area devices to standard mini-modules.

By integrating a Class AAA LED steady-state solar simulator, multi-channel source-meter units, independent temperature control modules, and intelligent automation software, the system enables simultaneous IV characterization, MPPT tracking, and long-term stability monitoring under controlled illumination and environmental conditions.

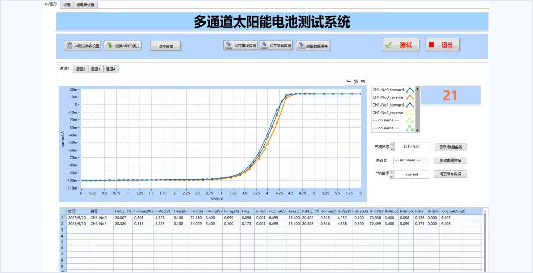

Unlike traditional single-channel test setups, this platform supports up to 19 independently controlled channels, allowing parallel testing of multiple samples in a single experiment. This significantly increases data throughput and shortens R&D validation cycles, making it ideal for perovskite material screening, process optimization, and lifetime assessment.

The system supports forward and reverse IV scanning, 9-point fitting methods, and customizable scan intervals. Each channel operates independently, enabling flexible parameter configuration for different devices within the same test run.

Electrical Testing Capabilities

| Parameter | Specification |

|---|---|

| Test Channels | Up to 19 (customizable) |

| Points per Channel | 8-point relay scanning |

| Voltage Range | 20–60 V (customizable) |

| Current Range | Up to 1 A |

| Channel Power | 20 W |

| Measurement Accuracy | 0.1% |

Real-time IV and PV curves are displayed and recorded for all channels simultaneously, with instant alarms triggered upon abnormal conditions.

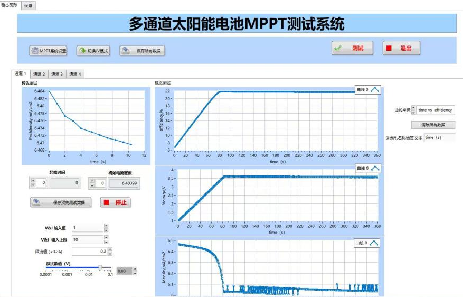

To address the hysteresis and transient behavior commonly observed in perovskite solar cells, the system integrates multiple MPPT algorithms.

Supported MPPT Algorithms

| Algorithm | Application |

|---|---|

| Perturb & Observe (P&O) | General MPPT tracking |

| Incremental Conductance (IncCond) | High-precision dynamic tracking |

| Constant Voltage (CV) | Stable operation point testing |

These algorithms ensure accurate maximum power point tracking under steady-state illumination and during long-term aging experiments.

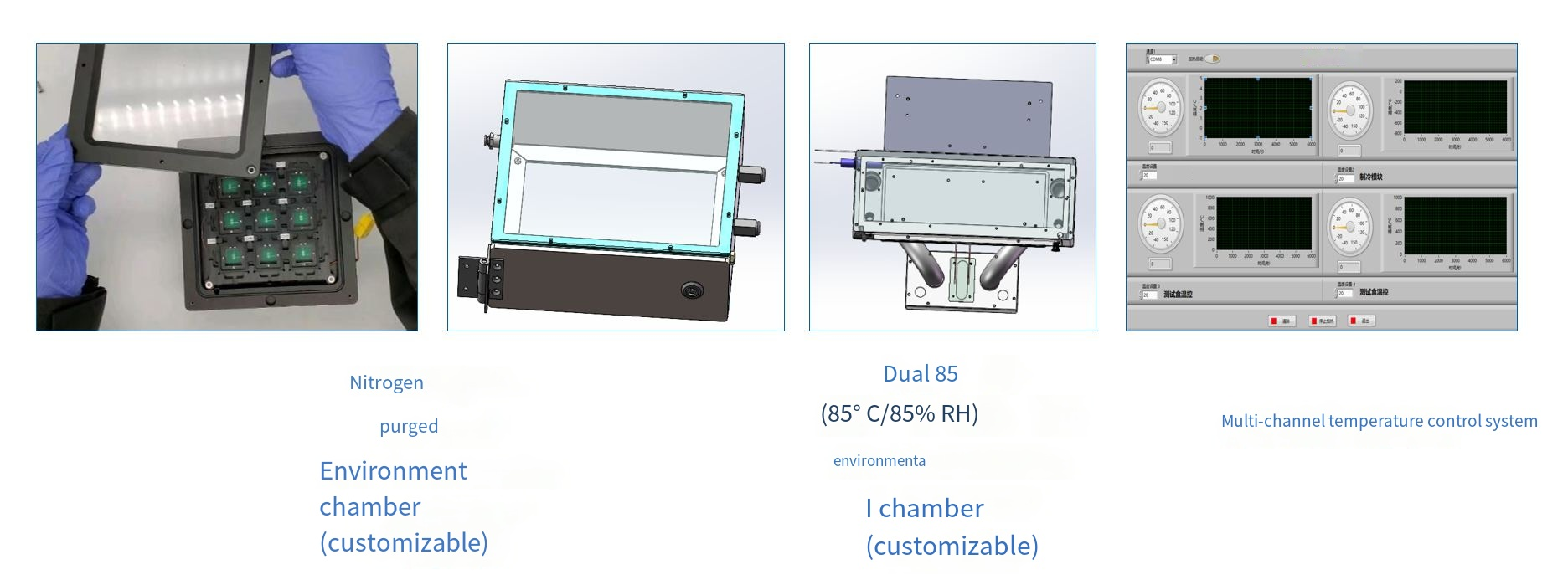

Each test channel is equipped with an independent temperature control module, enabling precise thermal regulation and monitoring.

Temperature Control Specifications

| Parameter | Specification |

|---|---|

| Temperature Range | -10°C to 100°C |

| Control Accuracy | ±2°C |

| Temperature Monitoring | Real-time curve display |

| Cooling Capability | Rapid cooling supported |

| Optional Modules | Humidity control (20–80% RH) |

This allows accurate evaluation of PV module performance and degradation under high-temperature, low-temperature, and combined light-thermal stress conditions.

The system is powered by an in-house developed intelligent software platform that supports fully automated testing workflows.

Software Capabilities

| Function | Description |

|---|---|

| Automated Scheduling | Timed IV & MPPT tests |

| Data Storage | Automatic naming and archiving |

| Data Export | Independent or merged channel data |

| Visualization | IV, PV, and temperature curves |

| Alarm System | Real-time abnormal status alerts |

| Operation Mode | 7×24 unattended testing |

This software architecture ensures high data integrity and traceability during long-term stability studies.

High-Throughput Parallel Testing

Multiple channels run simultaneously, significantly increasing experimental efficiency.

Perovskite-Focused Design

MPPT algorithms and hysteresis-aware IV testing are optimized for perovskite devices.

Flexible Device Compatibility

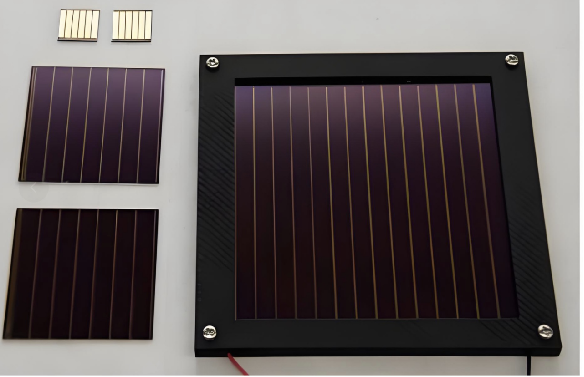

Supports glass and flexible substrates, small devices (≤25×25 mm), and modules up to 250×250 mm.

Modular & Customizable Architecture

Hardware and software configurations can be tailored to specific R&D scenarios.

Long-Term Reliability

Designed for continuous operation with stable data acquisition and environmental control.

The Multi-channel PV Module IV+MPPT Steady-State Test System is widely used in:

Perovskite solar cell material screening

Laser-scribed perovskite device performance evaluation

Thin-film and tandem PV module stability testing

Long-term light soaking and lifetime assessment

Process optimization and quality control in pilot lines

University laboratories and photovoltaic research institutes

| Category | Specification |

|---|---|

| Light Source | Class AAA LED steady-state solar simulator |

| Test Channels | Up to 19 independent channels |

| IV Accuracy | 0.1% |

| MPPT Algorithms | P&O / IncCond / CV |

| Temp. Range | -10°C to 100°C |

| Humidity Control | Optional (20–80% RH) |

| Device Size | ≤25×25 mm to 250×250 mm |

| Data Management | Automated saving & export |

| Operation Mode | 24/7 unattended |

| Customization | Hardware & software configurable |

Multi-channel design enables parallel IV and MPPT testing. 3A LED simulator ensures stable AM1.5G illumination. Independent 25–100°C control keeps each module stable. Supports 50×50 to 300×300 mm modules for flexible testing.

MoreLED simulator delivers precise AM1.5G output with stable irradiance. Adjustable intensity ensures flexible testing for PV materials. Real-time LED temperature control maintains consistent light quality. Clean interface enables easy spectral and irradiance adjustments.

More1. Integrated AM0 light, thermal stage, and testing system in one cabinet. 2. Class A AM0 spectrum with extreme temperature simulation from -180°C to +150°C. 3. Multi-channel IV and MPPT testing enables high-throughput space PV evaluation. 4. Automated software supports 24/7 unattended stability and aging tests.

More1. Optical shaping delivers true parallel light with <5° collimation. 2. Class A+ spectrum ensures accurate perovskite response testing. 3. Large 300×300 mm uniform area supports device and module research. 4. Dual steady and pulse modes enable efficiency and stability tests.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582