40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

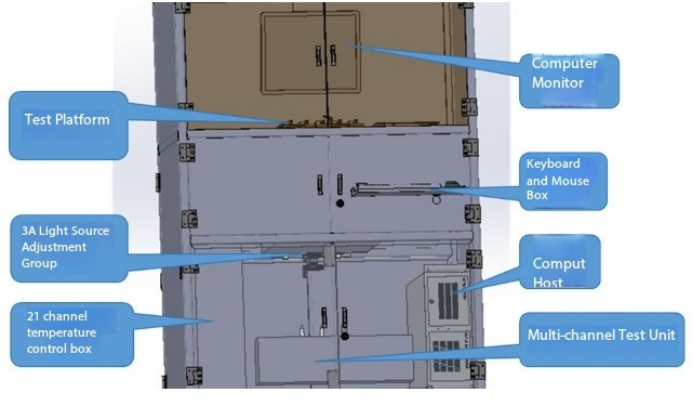

+86-17751173582The MCT10-300-20T Multi-Channel PV Module Steady-State Testing System is a high-throughput platform designed to evaluate the illumination stability, temperature reliability, and long-term electrical performance of thin-film, perovskite, and tandem PV modules. Equipped with a 3A-grade LED steady-state solar simulator, independent temperature-controlled channels, and a flexible multi-mode testing platform, the system supports continuous I-V scans, MPPT tracking, and degradation monitoring under precisely controlled conditions.

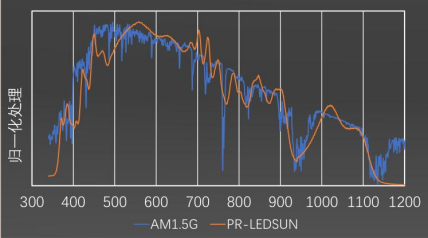

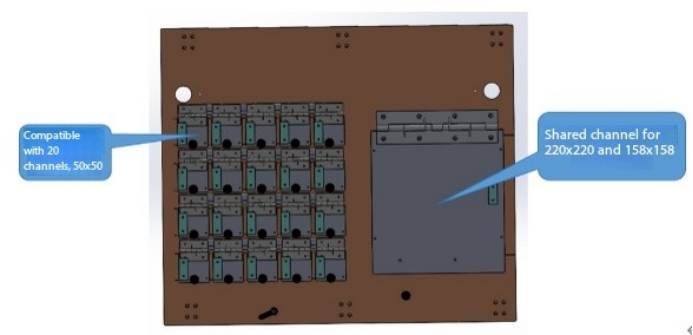

The Multi-Channel PV Module Steady-State Testing System accommodates module sizes from 50×50 mm to 300×300 mm, covering perovskite small cells, mini-modules, and flexible devices. The simulator supports selectable spectral ranges (300–1100 nm / 300–1200 nm), adjustable irradiance (100–1100 W/m²), and calibrated AM1.5G matching to ensure measurement accuracy.

Module Compatibility Table

| Supported Size | Dimensions (mm) | Substrate Type |

|---|---|---|

| Small Cells | 50×50 | Glass / Flexible |

| Mid-Size | 158×158 | Glass / Flexible |

| Mid-Size | 220×220 | Glass / Flexible |

| Mini-Modules | 300×300 | Glass / Flexible |

The testing platform integrates high-precision lifting and sliding mechanisms. The lifting module adjusts the light-source height from 10–40 cm with 0.1 cm resolution, while the horizontal sliding platform switches between multi-channel mode (up to 20 channels) and single large-module testing.

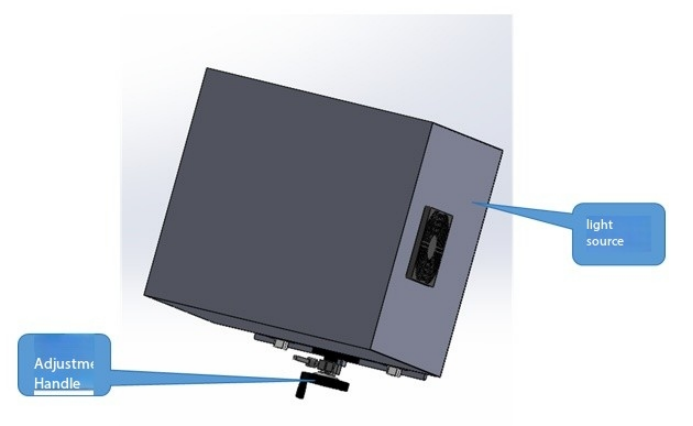

The LED steady-state solar simulator delivers industry-standard 3A performance, ensuring accurate optical exposure for long-duration stability studies.

Illumination Performance Table

| Parameter | Specification |

|---|---|

| Spectral Range | 300–1100 / 350–1100 / 300–1200 / 350–1200 nm |

| Irradiance Range | 100–1100 W/m² |

| Uniformity | ≤2% |

| Temporal Instability | ≤±2% |

| Spectral Match | A / A+ |

| Adjustable Distance | 10–40 cm (0.1 cm precision) |

| LED Lifetime | 10,000 h |

The combination of adjustable irradiance, high uniformity, and low time instability ensures that all modules experience consistent, repeatable illumination—an essential condition for light-soaking stability experiments in perovskite and thin-film PV research.

The system incorporates independent electrical source-measure units (SMUs) enabling simultaneous multi-channel testing without interference between channels. Each channel supports individual I-V sweeps, MPPT algorithms, and continuous monitoring of critical PV parameters.

Multi-Channel Electrical Specifications

| Electrical Item | Multi-Channel | Single Channel | Perovskite Single |

|---|---|---|---|

| Voltage Range | 10 V / 18 V | 80 V | 100 V |

| Current Range | 0.5–1 A | 20 A | 1 A |

| Min Voltage Range | 1 V | 10 V | 300 mV |

| Min Current Resolution | 5 μA | 1 mA | 100 nA |

| Accuracy | 0.1% | 0.1 mV / 0.1 mA | ±(0.025%+0.025%FS) |

This wide measurement range supports:

Perovskite pixel-level devices

Tandem mini-modules

High-current crystalline-silicon modules

The system allows each device to operate with its own electrical parameters, enabling realistic performance benchmarking across different material systems.

Each testing position integrates a dedicated heating plate with feedback-controlled thermal regulation that maintains stable and consistent temperatures, ideal for accelerated aging and thermal drift studies.

Temperature System Table

| Parameter | Specification |

|---|---|

| Temperature Range | 25–100°C |

| Stability | ±2°C |

| Feedback Accuracy | 0.1°C |

| Monitoring Method | Patch-type thermocouple |

| Display | Real-time temperature curves |

| Channel Operation | Fully independent |

Unlike shared heating environments, this design ensures that each sample receives identical but isolated thermal conditions—preventing cross-heating effects and improving reliability of data comparison.

The software is fully developed in-house and supports multi-channel control, real-time display, long-term monitoring, and automated data storage.

Software Capability Table

| Function | Description |

|---|---|

| I-V Test Modes | Forward/Reverse Scan, Dynamic IV, 9-Point Fit |

| MPPT Algorithms | Perturb & Observe, Incremental Conductance, Constant Voltage |

| Data Types | Voc, Isc, FF, PCE, Pmax, Imax, Vmax, Rs, Rsh |

| Data Logging | Automatic, timed, per-channel or unified |

| Temperature Display | Real-time curve, multi-channel monitoring |

| Multi-Channel Control | Independent on/off, parameter settings, temperature control |

This allows researchers to run long-duration experiments with minimal manual intervention.

The system's mechanical layout keeps all modules isolated and easy to access while maintaining a dust-resistant and stable testing environment.

Mechanical & Structural Features

| Component | Feature |

|---|---|

| Light Source | Downward-illumination structure |

| Platform | Left-right sliding for mode switching |

| Housing | Dust-proof enclosure |

| Cooling | Forced air circulation |

| Optional | Humidity control module |

Multi-Channel PV Module Steady-State Testing System is suitable for:

Perovskite module long-term light soaking tests

Tandem cell stability verification and MPPT efficiency studies

Thin-film module thermal and optical degradation analysis

High-throughput material screening in research institutions

PV module reliability labs conducting extended aging experiments

| Category | Details |

|---|---|

| Light Source | 3A LED, 100–1100 W/m², A/A+ spectral match |

| Spectrum Range | 300–1200 nm (optional combinations) |

| Module Support | 50×50 / 158×158 / 220×220 / 300×300 mm |

| Temperature System | 25–100°C, ±2°C stability, 0.1°C accuracy |

| Channels | 4 / 8 / 20 channels, independent control |

| Electrical Specs | Up to 100 V & 20 A |

| Software | IV/MPPT/Temperature tracking, auto-save |

| Dimensions | 1200 × 800 × 1800 mm |

| Cooling | Air cooling |

| Optional | Humidity control |

LED simulator delivers precise AM1.5G output with stable irradiance. Adjustable intensity ensures flexible testing for PV materials. Real-time LED temperature control maintains consistent light quality. Clean interface enables easy spectral and irradiance adjustments.

More1. Integrated AM0 light, thermal stage, and testing system in one cabinet. 2. Class A AM0 spectrum with extreme temperature simulation from -180°C to +150°C. 3. Multi-channel IV and MPPT testing enables high-throughput space PV evaluation. 4. Automated software supports 24/7 unattended stability and aging tests.

More1. Optical shaping delivers true parallel light with <5° collimation. 2. Class A+ spectrum ensures accurate perovskite response testing. 3. Large 300×300 mm uniform area supports device and module research. 4. Dual steady and pulse modes enable efficiency and stability tests.

More1. Multi-channel architecture enables parallel IV and MPPT testing. 2. Independent channel control ensures high-precision data acquisition. 3. Built-in MPPT algorithms handle perovskite hysteresis effectively. 4. Automated software supports long-term, unattended stability testing.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582