40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582Multi-Station Laser Engraving & Cutting Machine Technical Description

I. Structural Features (Designed for Industrial Demands)

・6 Independent Laser Heads: Simultaneously process multiple workpieces in a single cycle, reducing idle time by 70%.

・Modular Workstations: Supports rotary fixtures, conveyor belts, and pneumatic clamps for diverse materials (sheets/tubes/3D parts).

・High-Stability Gantry: Aerospace-grade aluminum frame with linear guide rails ensures micron-level repeat positioning accuracy (±0.01mm).

・Integrated Cooling System: Closed-loop chiller maintains laser source temperature at 25°±1°C during 24/7 operation.

・Automated Material Handling: Robotic arm-compatible ports enable seamless integration with smart factory systems.

II. Technical & Operational Advantages (Engineered for Peak Performance)

・Universal Material Compatibility: Processes metals (steel/aluminum/copper), engineered plastics (PC/PEEK), ceramics, and coated composites with zero tooling change.

・Intelligent Software Suite: Cloud-based ContourLaser™ OS supports DXF/AI/STEP files, real-time energy monitoring, and predictive maintenance alerts via IoT.

・Precision Without Compromise: 0.04mm minimum line width and 100,000+ dpi resolution for micro QR codes, medical device markings, and aerospace traceability.

・Energy-Efficient Operation: 30% lower power consumption vs traditional CO2 lasers, with auto-sleep mode during idle cycles.

III. Typical Applications (Cross-Industry Capability)

・Industrial Manufacturing: High-volume serial number engraving on automotive parts, CNC machining tool ID marking.

・Electronics & Semiconductors: FR4 circuit board depaneling, micro-component etching, stainless steel EMI shield cutting.

・Medical Device Production: FDA-compliant UDI codes on surgical instruments, titanium implant surface texturing.

・Precision Engineering: Barcode engraving on hydraulic valves, custom gasket cutting from 0.5mm shim stock.

・Consumer Goods: Personalized jewelry engraving, luxury packaging die-cutting, architectural model prototyping.

Dual-chuck design enables non-stop material processing. Synchronous cutting/loading doubles production output. Precision servo control maintains ±0.08mm accuracy. Smart chuck synchronization eliminates material waste.

MoreP-Series delivers industry-leading 120m/min cutting speed. Six-axis CNC control enables complex 3D pipe profiles. Automatic loading/unloading boosts production efficiency. Maintains ±0.1mm precision across all pipe diameters.

MoreFive-axis robotic cutting for complex 3D metal parts. High-power fiber laser handles thick and thin materials. Precision ±0.05mm cutting for automotive components. Smart programming reduces material waste significantly.

MoreUltra-precise laser cutting for flexible OLED panels. Non-contact process prevents display layer damage. Automated alignment ensures micron-level cutting accuracy. Compact design fits cleanroom production environments.

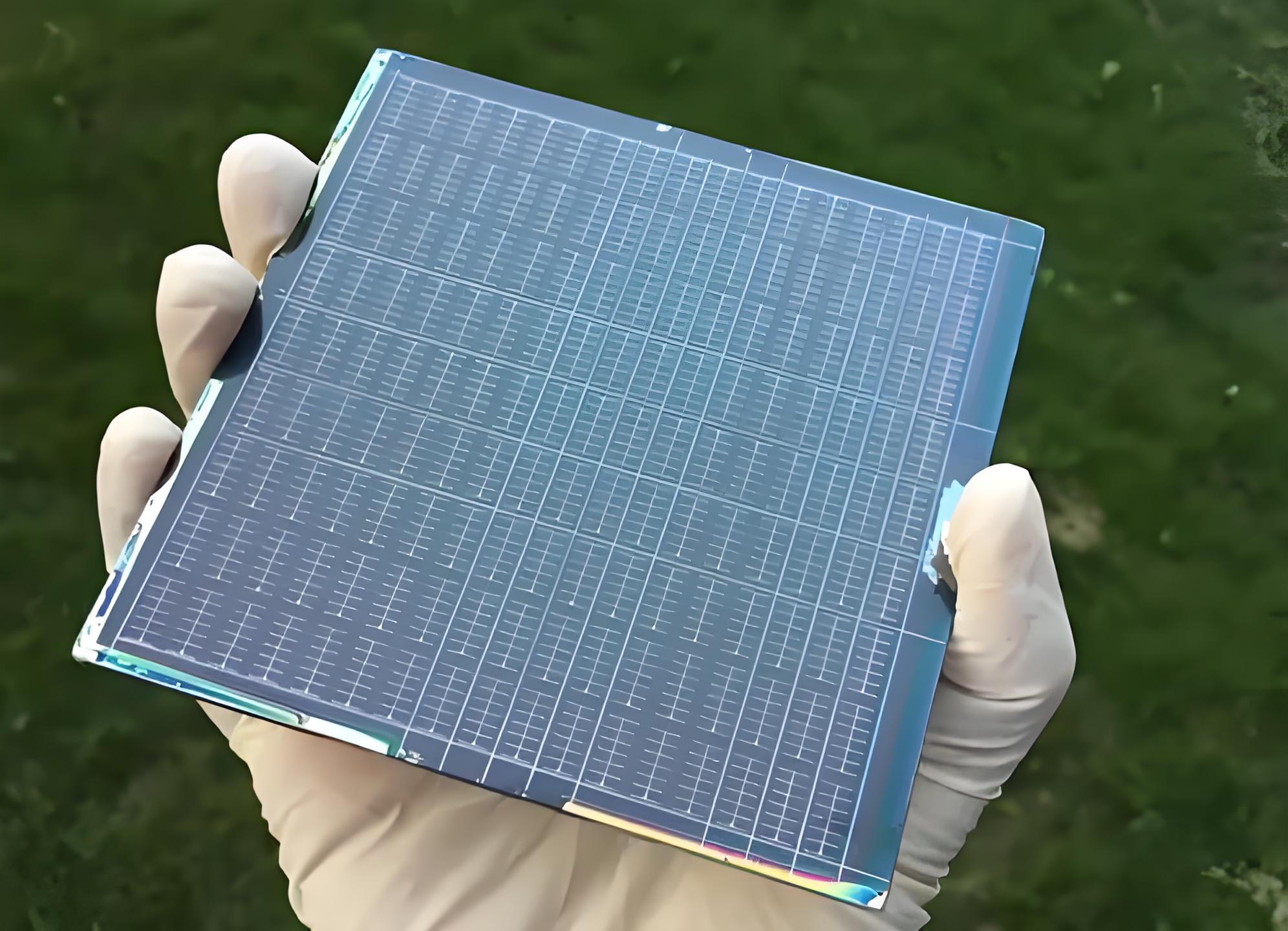

MoreNon-contact laser cutting for zero material loss. High-precision slicing for superior wafer quality. Automated operation boosts production efficiency. Low thermal impact preserves SiC properties.

MoreCold Laser Processing: Cuts glass without thermal cracks or chipping. Micron-Level Precision: Achieves clean edges with ≤20μm accuracy. Multi-Layer Capable: Processes laminated/tempered glass effortlessly. Industrial Reliability: 24/7 operation with minimal maintenance.

MoreVersatile Dual Function: Precision cutting AND engraving in one compact system. Non-Material Master: Perfectly processes wood, acrylic, leather, fabric, paper. User-Friendly Operation: Intuitive software & rapid setup for instant productivity. Industrial-Grade Results: Professional quality without industrial complexity.

MoreSpace-Saving Design: Compact benchtop unit fits any workshop or office. Precision Metal Cutting: Cuts steel, aluminum, copper with razor-sharp detail. Plug-&-Play Operation: User-friendly software, minimal training required. Industrial Performance: Professional results without industrial space needs.

MoreHigh-Power Fiber Laser: Delivers superior speed & cuts thick metals effortlessly. Exceptional Precision & Quality: Achieves clean, burr-free edges on intricate contours. Energy-Efficient & Cost-Effective: Low power consumption maximizes operational savings. Versatile & Reliable: Processes diverse metals (steel, aluminum, copper) with consistent results.

MoreUltrafine 5μm Laser Etching—Sub-micron precision for semiconductors & FPCs. 2000mm/s High-Speed Processing—4x faster vs chemical etching, zero waste. 200+ Material Compatibility—From glass to titanium alloys, non-contact. Intelligent HMI Control—Auto-focus & CAD integration, ISO certified.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582