40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

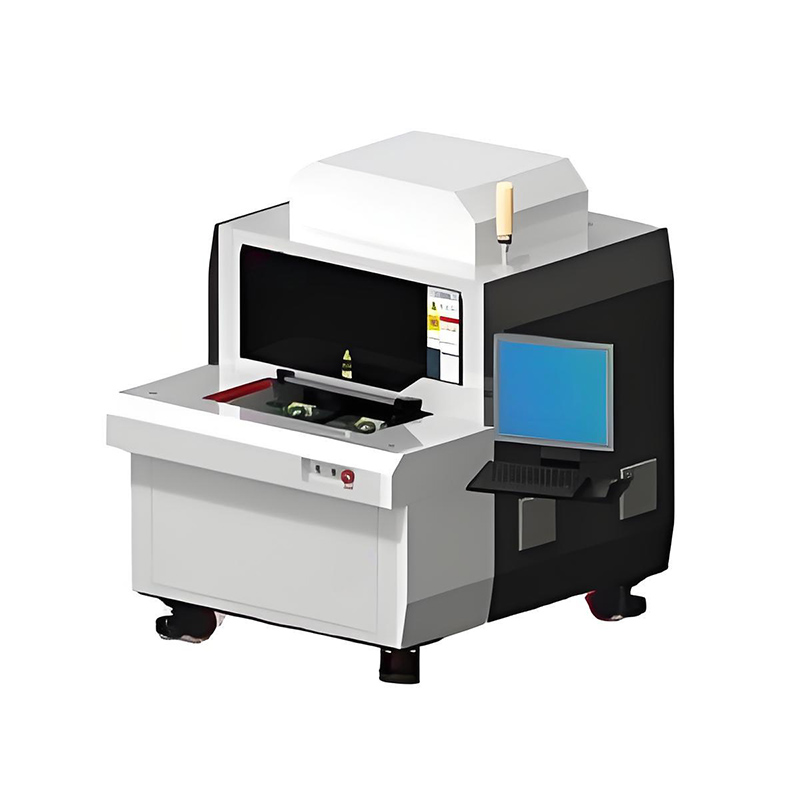

+86-17751173582The Dual-Station Solder Paste Laser Welding Equipment integrates a high-precision closed-loop temperature feedback system for real-time thermal regulation. Its automated tri-functional process enables seamless auto-positioning, precision solder paste dispensing, and laser welding execution within a single workflow. The core mechanical innovation lies in its synchronized dual-station architecture, allowing parallel processing operations while maintaining micron-level positioning accuracy (±5μm). Modular tooling stations support rapid fixture changeovers for diverse product geometries, and industrial-grade galvanometer scanning ensures consistent beam focal control across both stations.

Zero Thermal Damage Guarantee

Closed-loop temperature control actively prevents component burnout (ΔT≤±0.5°C), achieving >99.8% defect-free welds even on heat-sensitive substrates.

45% Operational Efficiency Boost

Concurrent dual-station processing eliminates idle time, completing 27-second cycle operations with automated material handling.

60% Cost Reduction

Dual-station workflow slashes labor requirements by 2 operators per shift and cuts energy consumption by 35% versus single-station systems.

Process Stability

Patented anti-dispersion laser optics maintain consistent spot size (<20μm variation) across 100,000+ weld cycles.

3C Electronics Manufacturing

Micro-welding of smartphone battery connectors (<0.3mm joints)

Camera module FPC bonding with ≤10μm positional accuracy

Automotive Micro-Components

Sensor housing hermetic sealing

ECU chip pin reflow without board deformation

Medical Device Assembly

Endoscope instrument welding (biocompatible Sn-Ag-Cu solder)

Implantable device encapsulation at ISO Class 5 cleanroom standards

Precision Industrial Components

Aerospace relay contacts (Cratering prevention)

Miniature relay welding under 5x magnification QA

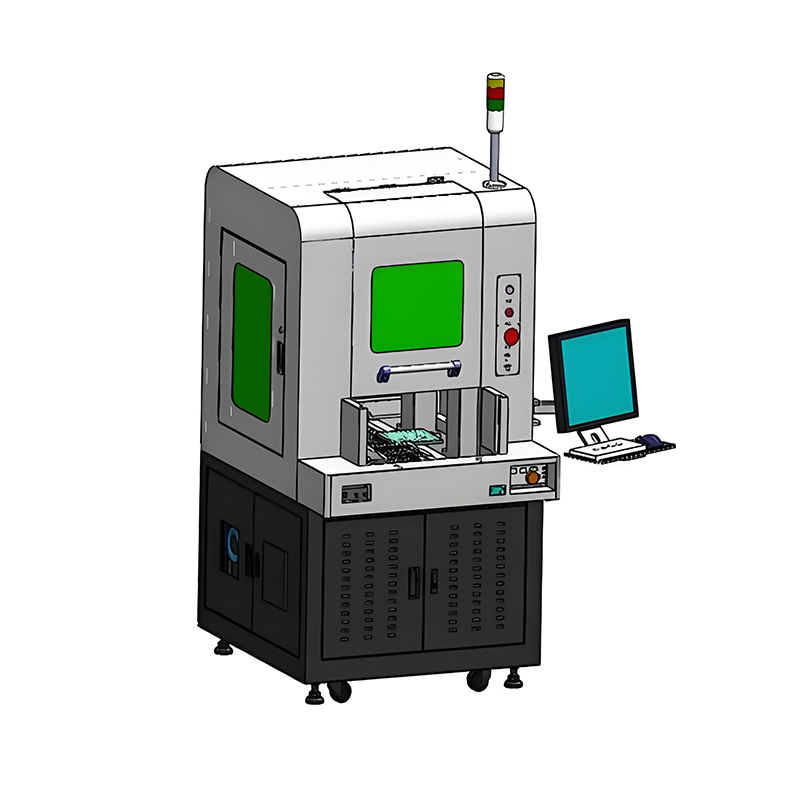

High-speed robotic laser welding for precision manufacturing. Flexible automation adapts to complex welding applications. Energy-efficient system reduces operational costs significantly.

MoreAir-cooled, gas-free operation for zero setup delays. Precise 0.1mm beam: splatter-free welds on thin metals. Plug & play: welds steel, aluminum, copper instantly

MoreAir-cooled handheld design for cordless, portable operation. 500W-1500W fiber laser enables precise, splatter-free welds. 60% lighter than water-cooled models, ideal for onsite jobs. Works on stainless, carbon steel, aluminum & copper.

MoreHigh-Precision Fiber Laser Welding. Minimal heat distortion, perfect for delicate parts. Fast Processing Speeds & Deep Penetration. Boost productivity with efficient, strong welds. Versatile Metals Welding: Steel, Aluminum, Copper. No filler material needed for most. User-Friendly CNC Control & Stable Performance. Ensures reliable, repeatable weld quality.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582