40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

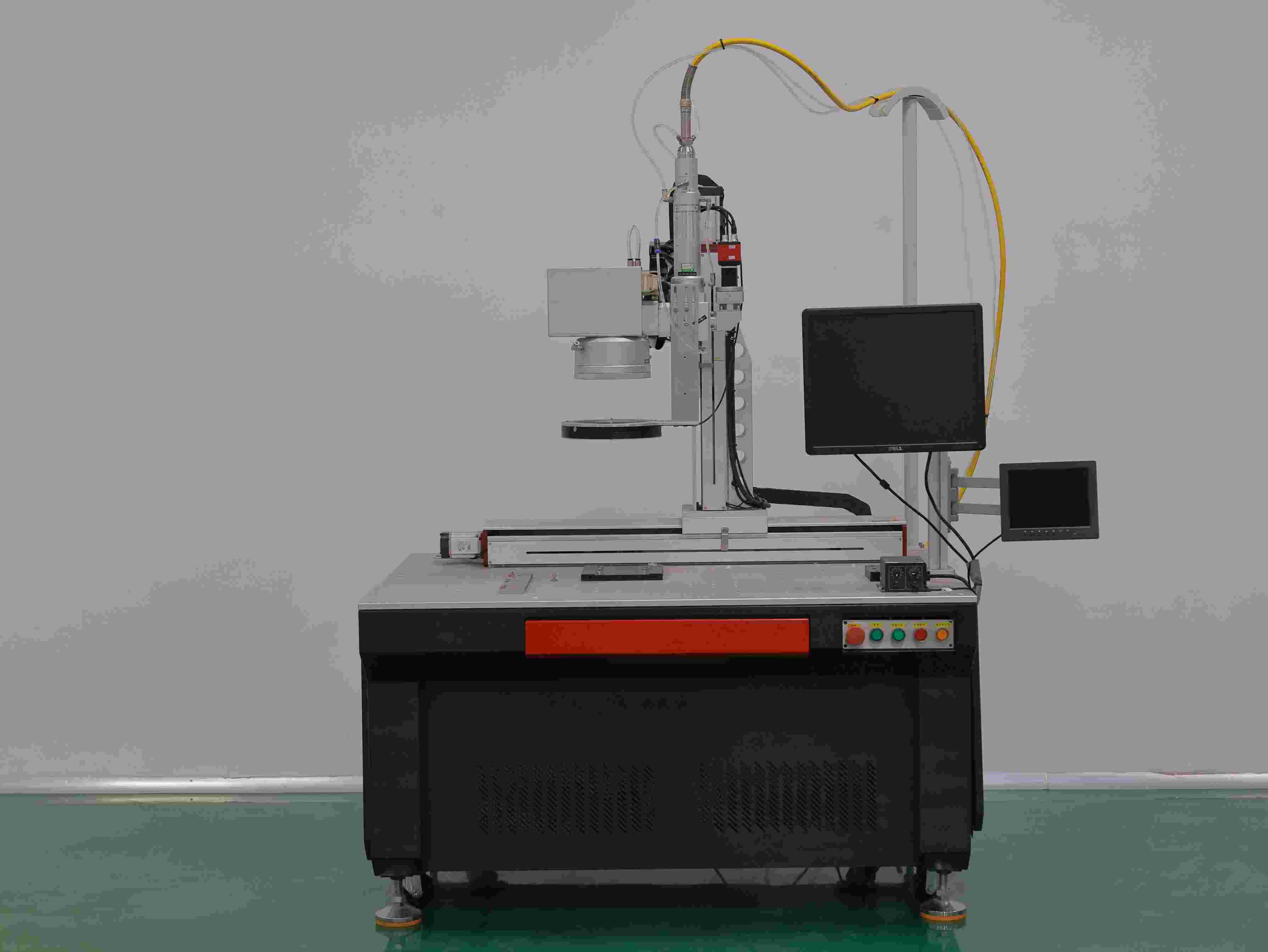

+86-17751173582Laser welding equipment is a high-end manufacturing system that utilizes high-energy-density laser beams to achieve precision material joining. By focusing laser energy through advanced optical systems, the device enables rapid melting and fusion of metals or non-metals within milliseconds, offering core advantages such as high efficiency, precision, and non-contact processing. With exceptional process adaptability and automation capabilities, laser welding systems are widely adopted in high-value industries including automotive, consumer electronics, medical devices, and aerospace, making them a pivotal technology in modern smart manufacturing.

Modular Design: The system adopts a modular architecture, allowing flexible configuration of laser sources, welding heads, and motion control systems to meet diverse processing requirements.

High-Precision Motion System: Equipped with rigid robotic arms or linear motor stages, ensuring stability and repeatable micron-level positioning accuracy for delicate welding tasks.

Intelligent Control System: Integrated PLC and industrial PC enable automated programming and real-time monitoring, featuring seam tracking and adaptive power adjustment for consistent weld quality.

User-Friendly Interface: A high-resolution touchscreen with intuitive HMI supports one-touch parameter setup and process database access, reducing operator training time.

Compact Footprint: Space-saving design facilitates integration into workshops or automated production lines.

High Efficiency & Energy Saving: Fiber or semiconductor lasers achieve over 30% electro-optical efficiency, reducing energy consumption by 50% compared to conventional methods.

Non-Contact Processing: Eliminates mechanical stress on workpieces, ideal for thin sheets and sensitive components like electronics.

Broad Material Compatibility: Welds reflective metals (aluminum, copper) and dissimilar materials via adjustable pulsed/continuous waveforms.

Eco-Friendly Operation: Minimizes consumables (e.g., filler wires) and emissions, aligning with sustainable manufacturing standards.

Process Reliability: Built-in temperature feedback and optical path calibration ensure defect-free seams (e.g., no porosity) during prolonged operation.

Automotive: Battery tab welding, lightweight structural component joining.

Consumer Electronics: Smartphone frames, camera modules, and flexible PCB soldering.

Medical Devices: Hermetic sealing of surgical tools and implantable devices.

Aerospace: High-temperature alloy welding for turbine blades and fuel conduits.

Household Hardware: Mass production of kitchenware seals and sensor housings.

High-speed robotic laser welding for precision manufacturing. Flexible automation adapts to complex welding applications. Energy-efficient system reduces operational costs significantly.

MoreTwin workstations cut cycle time 50% with parallel processing. Precision laser melts solder paste with zero thermal damage. 0.3mm micro-spot welds fine-pitch ICs/BGA components.

MoreAir-cooled, gas-free operation for zero setup delays. Precise 0.1mm beam: splatter-free welds on thin metals. Plug & play: welds steel, aluminum, copper instantly

MoreAir-cooled handheld design for cordless, portable operation. 500W-1500W fiber laser enables precise, splatter-free welds. 60% lighter than water-cooled models, ideal for onsite jobs. Works on stainless, carbon steel, aluminum & copper.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582