40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

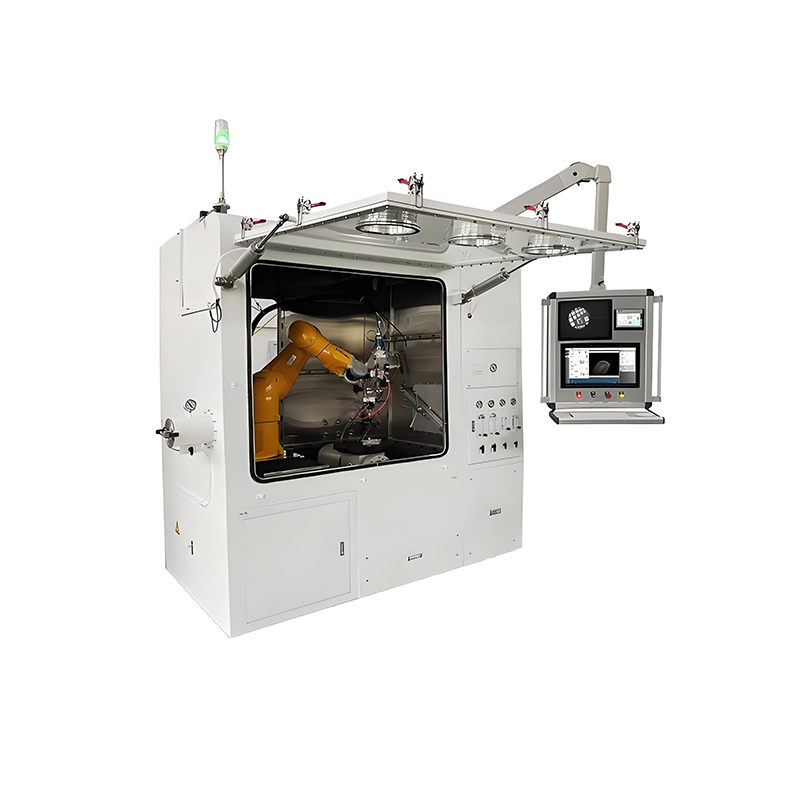

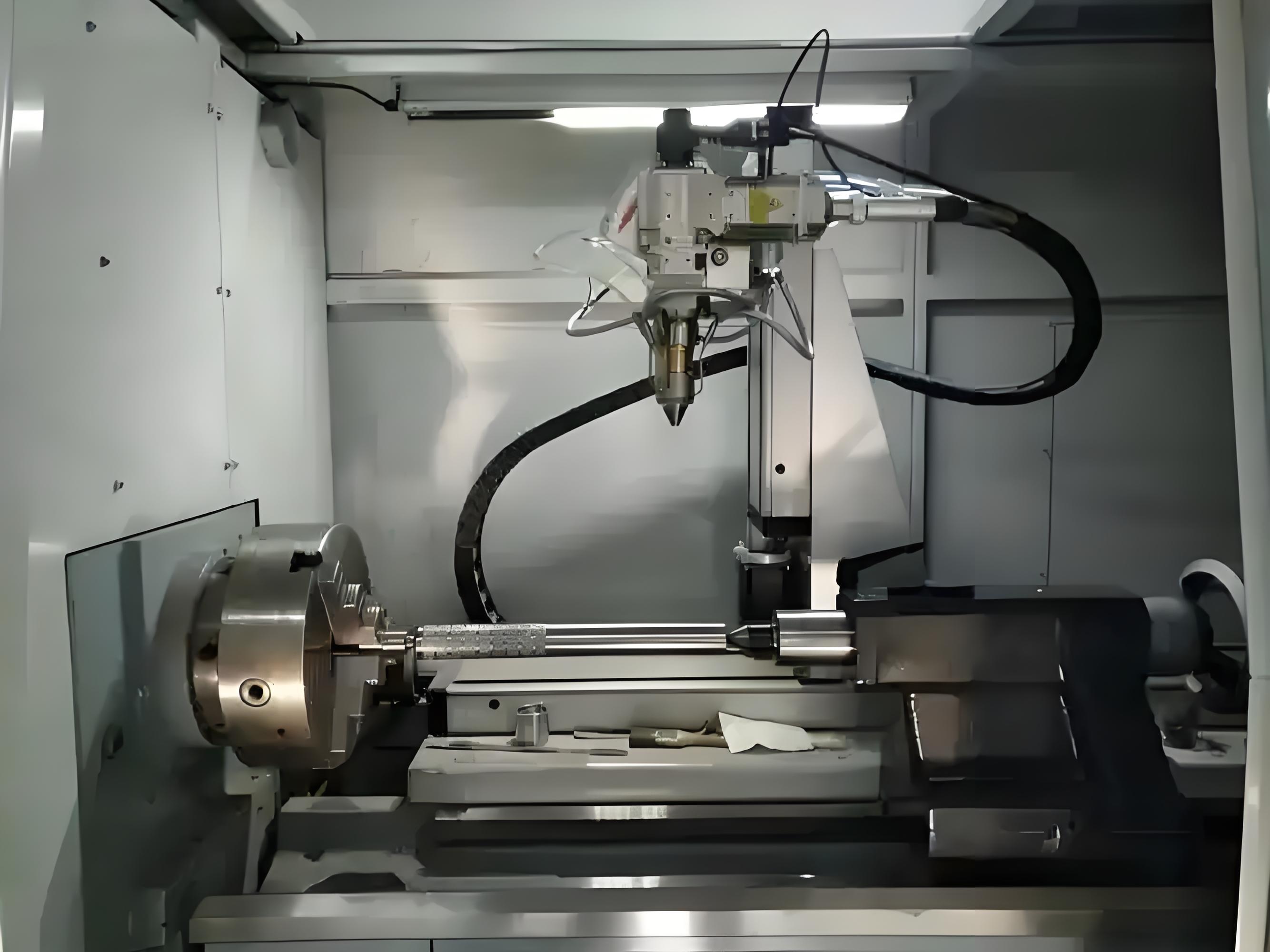

+86-17751173582Laser cladding equipment utilizes high-energy laser beams to fuse metal or ceramic powders onto substrate surfaces, creating specialized coatings that enhance wear resistance, corrosion resistance, and high-temperature performance. This advanced technology is widely adopted in industries such as mechanical manufacturing, aerospace, and automotive.

Key Features

Precision Coating – Forms metallurgically bonded layers with superior surface properties

Material Versatility – Compatible with various metal and ceramic powders

Minimal Thermal Impact – Preserves substrate integrity with controlled heat input

Automated Operation – Integrated control systems ensure consistent quality

Advantages

Improves surface performance without compromising base material

Enables cost-effective part restoration and modification

Supports sustainable manufacturing through material-efficient processes

Applications

Industrial Components – Extends service life of wear-prone parts

Aerospace Parts – Provides protective coatings for critical components

Automotive Systems – Enhances durability of engine and transmission elements

Simultaneous 5-axis control enables complex 3D part machining. Integrated rotary table processes large curved surfaces. Smart collision avoidance ensures uninterrupted production.

MorePrecision laser melting builds complex metal parts layer by layer. Closed-loop control ensures consistent high-density part quality. Multi-material capability for titanium, steel, and alloys.

MoreUltra-precise laser annealing for advanced chip manufacturing. Uniform energy distribution ensures consistent wafer treatment. Non-contact process prevents semiconductor surface damage. Automated calibration adapts to various wafer specifications.

MoreEco-friendly laser cleaning replaces chemical treatments. Precision cleaning without damaging base materials. Lightweight design enables easy operation anywhere. Low maintenance with long-lasting fiber laser source.

MorePrecision welding for high-efficiency EV battery production. Fully automated system boosts speed and reduces defects. Robust design ensures stable, long-term manufacturing performance. Customizable solutions for various battery types and sizes.

MoreUltra-precise laser transfer for Micro LED arrays. High-speed mass production with micron accuracy. Non-contact process ensures zero damage. Modular design for flexible production scaling.

More

40px

80px

80px

80px

Lecheng Intelligence Technology (Suzhou) Co., Ltd.

Phone

+86-17751173582