Beyond Perovskite: Lecheng Intelligent's Laser Technology Powers New Developments in Hydrogen Fuel Cells and Precision Electronics

1. The Precision "Stitcher" for the Heart of Hydrogen Power: Bipolar Plate Laser Welding Technology

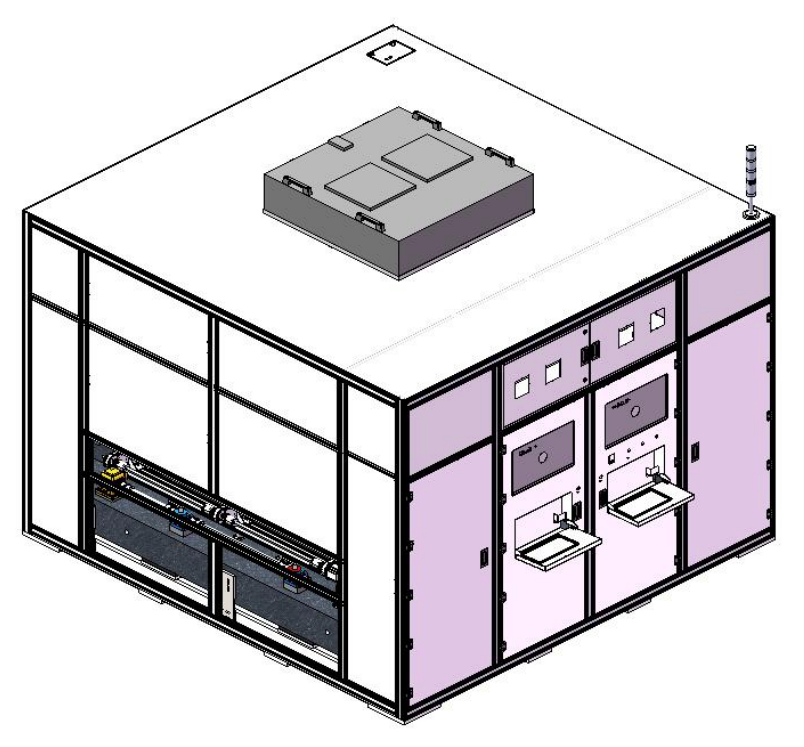

In the green energy wave, hydrogen fuel cells are hailed as the "ultimate energy solution," and the manufacturing quality of their core component – the bipolar plate – directly determines the cell's performance, lifespan, and safety. Lecheng Intelligent has precisely entered this high-end manufacturing arena with its high-performance Hydrogen Fuel Cell Bipolar Plate Laser Welding Equipment. This equipment features an innovative dual-head, three-station design that cleverly separates the loading/unloading processes from the welding operation. Utilizing robots coordinated with vision systems enables rapid material handling, ensuring highly efficient continuous operation and significantly boosting production capacity. Welding precision is a core metric of the equipment; Lecheng's system achieves micron-level processing with a weld seam width of just 0.08mm and a positional accuracy of up to ±0.02mm. This high-precision, low-thermal-stress welding method ensures excellent sealing for the bipolar plate's gas flow channels, effectively preventing reactant gas leakage and providing reliable structural integrity for the fuel cell. This customized solution highlights Lecheng Intelligent's capability to deeply integrate laser processes with automation technology to overcome advanced manufacturing challenges.

2. Enabling a Miniaturized World: Micro-Nano Processing Tools for Precision Electronics

As electronic products trend towards lighter, thinner, shorter, and more high-performance designs, the processing accuracy required for internal components demands near-extreme precision. Leveraging its profound expertise in precision micro-nano laser equipment, Lecheng Intelligent provides various cutting-edge solutions for processing materials like FPC (Flexible Printed Circuit Boards), glass substrates, and special thin films. For Precision Laser Drilling of FPCs, their equipment employs a galvanometer-stage four-axis linkage system, capable of drilling through-holes and blind holes with a minimum aperture of 50μm, at speeds up to 300 holes/second, meeting the manufacturing needs of high-density interconnect boards. In the realm of glass processing, their machines can handle materials like high-aluminum glass and silicate glass, with a maximum processing thickness of 10mm, while keeping glass chipping controlled below 10μm, ensuring product strength and yield. Furthermore, Lecheng specializes in using femtosecond lasers for precision thin-film etching, achieving ultra-fine processing with 15μm line spacing and a heat-affected zone of less than 10μm; and using picosecond lasers for cover film laser ablation, replacing traditional, highly polluting wet processes. These technologies are widely used in medical devices, consumer electronics, semiconductors, and more, serving as key enablers for the iteration and upgrade of modern technological products.

3. Driven by R&D: Powering Customized Laser Solutions Across Multiple Industries

Lecheng Intelligent's ability to provide leading laser equipment across diverse fields is fundamentally powered by its strong in-house R&D capabilities and a customer-centric philosophy of customized service. The company's founder, Mr. He Le, brings a Tsinghua University physics background and extensive experience in laser industry project management. He leads a core team whose members have deep expertise in laser and automated non-standard equipment. The company possesses robust optical design capabilities, allowing it to meet customized requirements for beam shaping and beam splitting. It also independently develops equipment control software, ensuring flexibility and stability. From achieving high-sealability welding for hydrogen fuel cells to enabling micron-level processing for precision electronic components, Lecheng Intelligent's successful case studies validate the high adaptability of its technological platform. The company insists on deep collaboration with leading enterprises across various industries to thoroughly understand manufacturing pain points, enabling it to respond rapidly with full-chain services encompassing process verification, equipment customization, and after-sales support. This dual-driven model of "Technology + Service" allows Lecheng Intelligent to continuously break through application boundaries and consistently empower high-tech manufacturing.