LeCheng Intelligent Unveils Fully Automated Laser Scribing System, Boosting Large-Area Perovskite Solar Cell Production

Introduction: The Challenge of Scaling Perovskite Technology

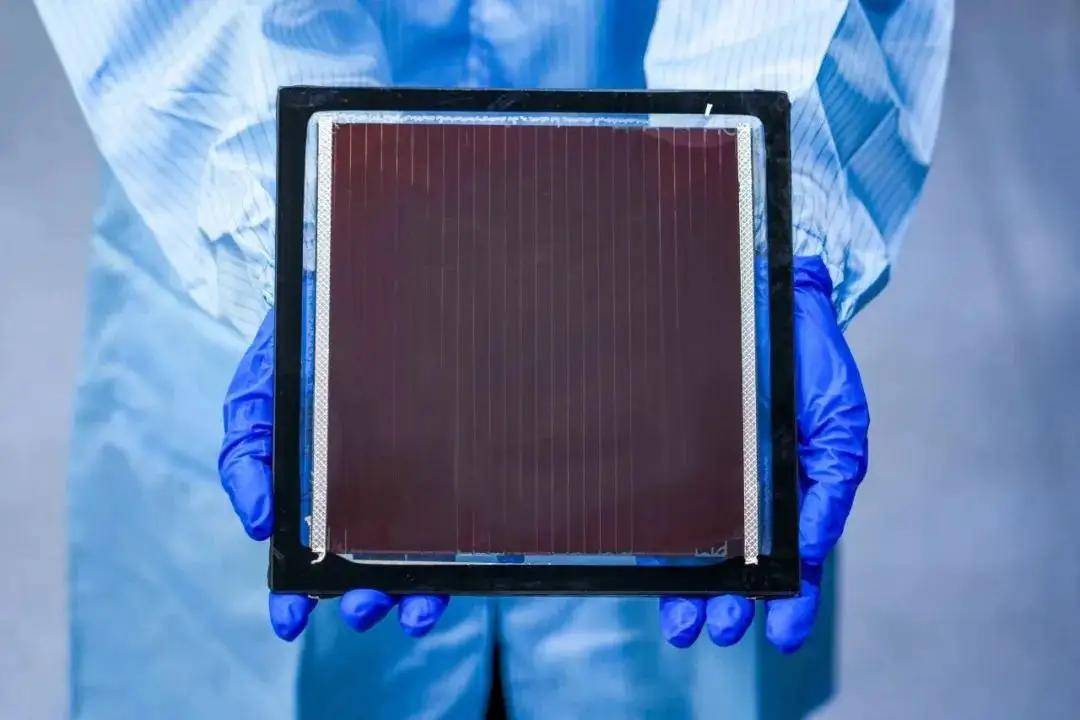

The transition to renewable energy is accelerating, and perovskite solar cells (PSCs) stand at the forefront of next-generation photovoltaic technology due to their high efficiency potential and low-cost manufacturing. However, a significant bottleneck has been the scalable and precise patterning of large-area modules to ensure high performance and longevity. Traditional methods often struggle with consistency, speed, and thermal damage control on an industrial scale. Addressing this critical challenge, LeCheng Intelligent Technology (Suzhou) Co., Ltd. has launched its state-of-the-art Fully Automated Thin-Film Battery Laser Scribing Equipment. This innovative system is engineered specifically for high-volume production, enabling manufacturers to achieve unprecedented precision and yield in creating monolithic series-connected PSC modules.

Core Innovation: Precision and Flexibility in Large-Area Scribing

LeCheng's laser scribing system is built around a robust three-station design (loading, scribing, unloading) that facilitates continuous, unattended operation, which is essential for mass production. The most striking feature is its capability to handle extra-large substrates up to 2.4 meters x 1.2 meters, a format that is becoming the industry standard for reducing balance-of-system costs. At the heart of its precision is an advanced optical system capable of supporting up to 24 independent laser beams. This multi-beam beam-splitting technology allows for simultaneous, parallel scribing of multiple cell interconnections, dramatically increasing throughput compared to single-beam systems. Crucially, the spacing between each beam is flexibly adjustable, providing manufacturers with the versatility needed for different module designs and P1, P2, P3 scribing patterns without requiring hardware changes.

The equipment's fully enclosed transmission structure is another key advantage, maintaining a clean, controlled environment around the substrate to prevent contamination during the critical scribing process. Furthermore, LeCheng's entirely self-developed control software offers unparalleled flexibility and stability. It allows for seamless integration of various positioning methods, including advanced vision systems, ensuring that the scribing accuracy is maintained across the entire panel, even at the micron level. This combination of large-format handling, multi-beam efficiency, and intelligent software makes the system a complete solution for overcoming the scalability hurdles in perovskite manufacturing.

Operational Excellence: Enhanced Stability and Smart Manufacturing

Beyond its core scribing capabilities, LeCheng's equipment is designed for operational excellence in a demanding factory environment. The automation system incorporates advanced control and sensory hardware to ensure exceptional mechanical stability and reliability, minimizing downtime. A significant feature for quality control and traceability is the integrated high-definition monitoring system. This system continuously records the scribing process in real-time, allowing engineers to monitor production quality remotely and store data for later analysis. This capability is vital for identifying process drift, troubleshooting issues, and maintaining consistent product quality, aligning with the principles of Industry 4.0 and smart manufacturing.

The system's modular design is a key cost-saving benefit. By utilizing a common equipment main body structure and swapping out laser sources and optical modules, the same platform can be configured for the different scribing stages (P1, P2, P3). This significantly reduces the initial investment, footprint, and long-term maintenance and training costs for manufacturers. By offering a low-cost-of-ownership model without compromising on performance, LeCheng Intelligent is not just selling a machine but a sustainable partnership, empowering perovskite producers to scale their operations efficiently and compete effectively in the global solar market.

Keywords:

perovskite laser scribing machine

large-area perovskite production equipment

automated solar cell laser patterning

P1 P2 P3 laser scribing system

monolithic perovskite module manufacturing

thin-film solar cell laser equipment