The Energy Harvesting Imperative

As wearable technology advances from fitness trackers to medical monitors and augmented reality glasses, power autonomy remains the critical bottleneck. Conventional batteries limit device functionality and design freedom, while rigid solar solutions compromise wearability. Enter ultrathin all-perovskite photovoltaic cells – the breakthrough technology enabling truly self-sustaining wearable ecosystems.

Why Perovskites Dominate Wearable Solar

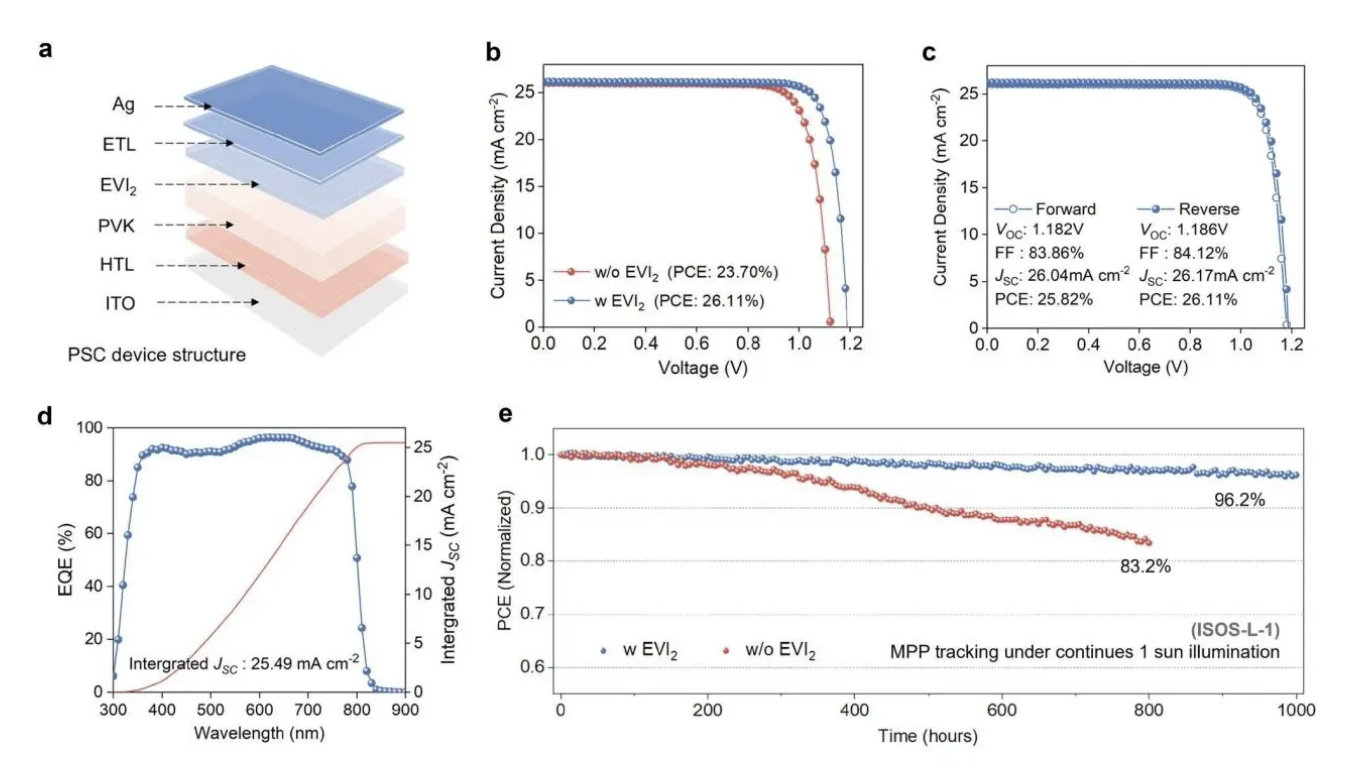

Unmatched Power-to-Weight Performance

Record Efficiency: All-perovskite tandem cells now achieve >26% PCE (Science, 2023) – nearly doubling silicon's power density

Ultralight Form Factor: <3μm active layers enable <0.1kg/m² specific weight – 50x lighter than crystalline silicon

Bending Stability: Maintain >90% efficiency after 10,000 cycles at 2mm curvature radius (Nature Energy, 2024)

Superior Low-Light Harvesting

Indoor Performance: Generates 150-350μW/cm² under 200-1000 lux – critical for medical patches and smartwatches

Angular Tolerance: <15% power drop at 60° incidence vs. >40% for rigid PV

The Laser Processing Advantage

At LEC Laser, we've pioneered the precision laser scribing techniques enabling commercial-scale perovskite wearable integration:

Critical Manufacturing Breakthroughs

Process | LEC Laser Innovation | Performance Impact |

|---|---|---|

P1 Patterning | Ultrafast (355nm) laser ablation | <15μm scribe width with zero substrate damage |

P2 Interconnection | Dynamic beam shaping technology | <0.5Ω series resistance at interconnection points |

Edge Isolation | Non-thermal femtosecond processing | Eliminates edge recombination losses |

"Our selective laser ablation system achieves 99.9% perovskite layer removal without HTL damage – the holy grail for high-yield flexible module production." – Dr. Wei Chen, CTO

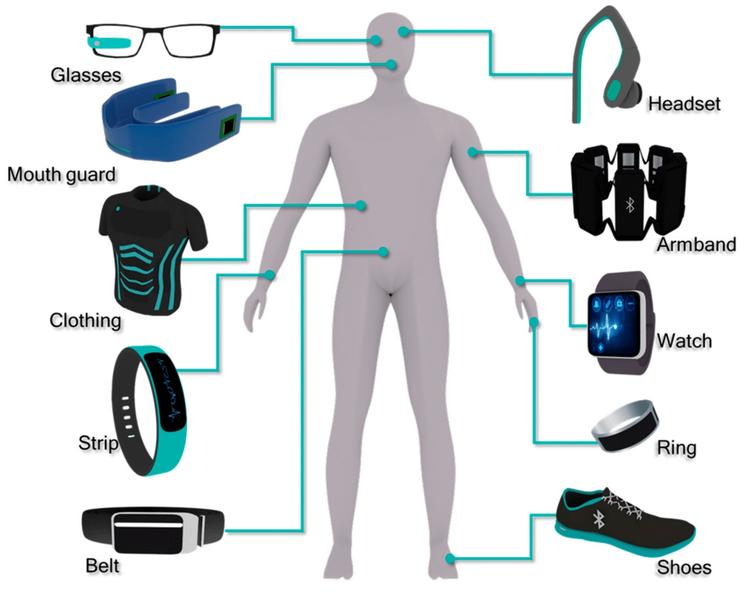

Emerging Applications & Market Growth

Revolutionizing Wearable Categories:

Medical Diagnostics: Continuous glucose monitors with perpetual power

Military Tech: Self-charging tactical goggles and soldier systems

Smart Textiles: Solar-powered heating jackets (15W/m² output demonstrated)

Consumer Electronics: 24/7 active smartwatches with unlimited runtime

Commercialization Timeline:

2024: First consumer products launching (Samsung Galaxy Watch 7 solar edition)

2026: Projected $1.2B wearable PV market (IDTechEx)

2028: 30% of wearables to integrate energy harvesting (Gartner)

Overcoming Stability Challenges

Recent advances address perovskite's historical limitations:

Encapsulation: Atomic-layer-deposited barriers enable >10,000hr operational stability

Lead Sequestration: Novel polymer matrices reduce Pb leakage to <0.1ppb

Thermal Management: Graphene heat-spreaders maintain performance at 45°C skin contact

The Road Ahead

As laser processing enables narrower scribe lines (<10μm) and monolithic integration, we're approaching 35% module geometric fill factors – translating to 50μW/cm² continuous power generation under office lighting.

At LEC Laser, we're driving this revolution with our third-generation laser scribing platforms featuring:

AI-powered real-time process monitoring

Dynamic focus control for curved surfaces

<1μm alignment precision for multi-layer devices

Ready to integrate solar harvesting into your wearable designs? Explore our perovskite laser patterning solutions at le-laser.com/perovskite-wearables