Perovskite solar modules (PSMs) have emerged as a promising photovoltaic technology due to their high efficiency and low manufacturing costs. However, the commercialization of PSMs faces significant challenges in achieving precise and reliable laser scribing processes for series interconnection. The laser scribing quality directly impacts the geometric fill factor (GFF), series resistance, and ultimate conversion efficiency of solar modules. This article systematically examines the monitoring techniques and quality control strategies for P1, P2, and P3 laser scribing processes that are essential for improving production yield in industrial manufacturing.

Scribing Step | Performance Requirements |

|---|---|

P1 | 1. Adjacent transparent conductive layer units must achieve electrical isolation; |

P2 | 1. Must effectively remove the ETL/PSK/HTL structure on the surface of the TCO or conductive bottom layer, with minimal damage to the underlying layer; |

P3 | 1. Adjacent Au (Gold) strips must achieve electrical isolation; |

1 The Critical Role of Laser Scribing in PSM Fabrication

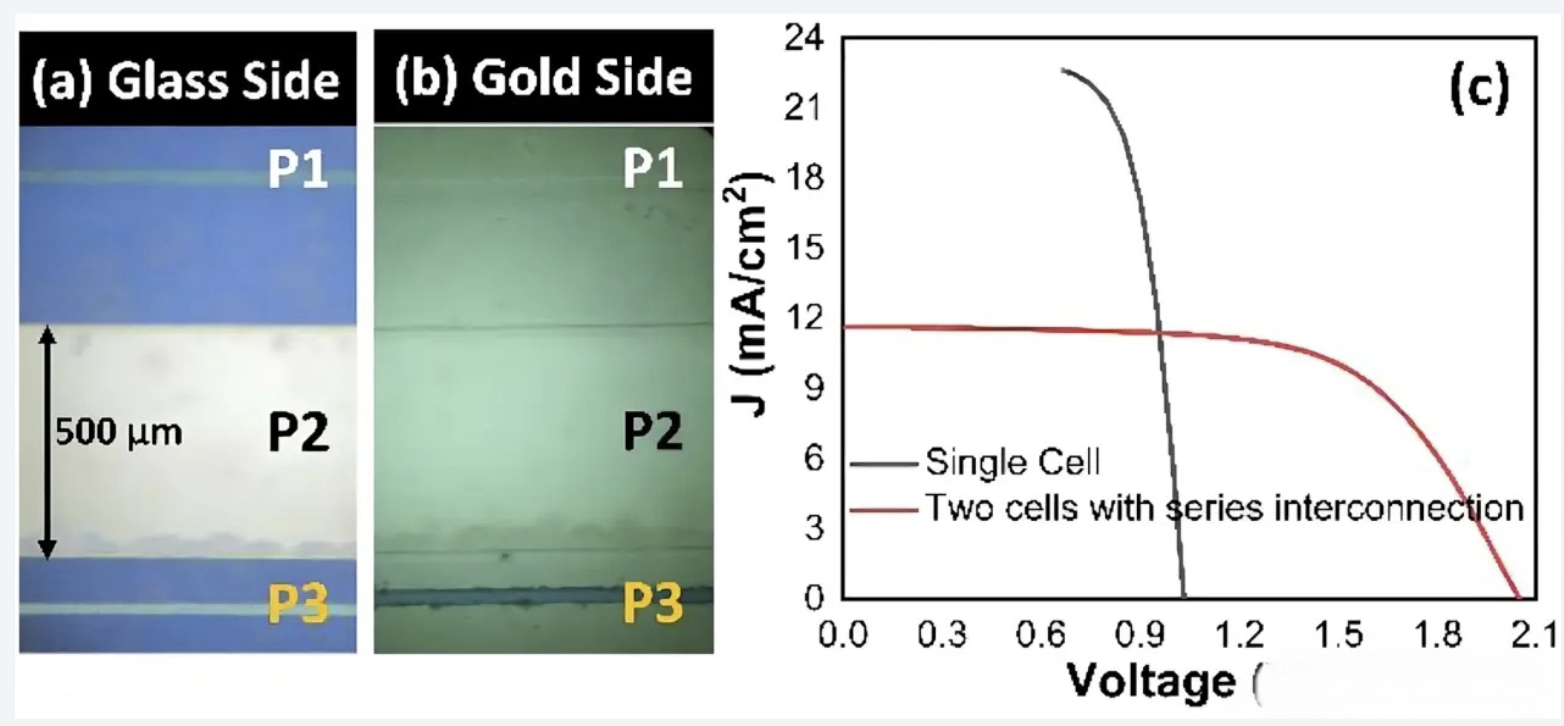

The series interconnection of perovskite solar cells requires three precise laser scribing steps: P1, P2, and P3. The P1 process isolates the transparent conductive oxide (TCO) layer on the substrate, creating individual cell segments. The P2 process penetrates multiple functional layers (ETL/perovskite/HTL) to expose the underlying TCO layer, establishing series connections between adjacent cells. The P3 process isolates the back electrode to complete the electrical separation.

The quality of these scribing processes directly determines the module's performance parameters. Imperfect scribing can lead to electrical shunts, increased series resistance, and reduced active area, ultimately diminishing the overall efficiency and reliability of the solar module.

2 In-situ Monitoring Techniques for Laser Scribing Quality

2.1 Advanced Imaging Systems

Real-time monitoring systems such as the Melano Perovskite Online Imaging Micro-testor utilize CCD digital imaging and computer vision technology to perform high-magnification optical amplification and imaging analysis. This system enables online detection of P1/P2/P3 laser scribing dimensions and defects with remarkable precision, achieving ±3μm accuracy in line width and spacing measurements. The system can complete single-point dimension detection in ≤3.5 seconds and full-cell surface scanning in ≤120 seconds, providing immediate feedback for process adjustment.

The imaging system automatically annotates dimensions and generates standardized data documents, allowing researchers to quickly access and analyze scribing morphology. This technology significantly enhances the repeatability and reliability of the scribing process, contributing to improved production yield.

2.2 Automated Electrical Testing Systems

Specialized automated detection systems have been developed for assessing P1 scribing effectiveness. These systems employ multiple probe arrays arranged in staggered configurations to automatically measure the resistance across each P1 scribe line. The system moves laterally along the module, with odd and even numbered probes testing alternating scribe lines to determine whether complete electrical isolation has been achieved.

This automated approach can handle modules with numerous series-connected cells, unlike manual testing methods which are impractical for large-area modules. The system records resistance values across the module and can identify specific locations where scribing is incomplete, enabling targeted process corrections.

3 Quality Optimization Strategies for Each Scribing Step

3.1 P1 Scribing: TCO Layer Isolation

The P1 process requires complete removal of the TCO layer without damaging the underlying substrate. For glass/FTO substrates (thickness >600 nm), optimal results are achieved with repetition rates of 25-80 kHz and average power of 675 mW, producing clean scribes without material accumulation.

For glass/ITO substrates (approximately 200 nm thick), lower frequencies (25 kHz) can cause localized overheating and microcracks due to concentrated laser energy. Similarly, for flexible PEN/ITO substrates, the average power must be controlled below 633 mW, combined with mechanical cleaning processes to reduce edge height from 8000 nm to 4000 nm.

Research indicates that optimal P1 parameters typically involve laser power of 1.8-2.4 W and scribing speeds below 2500 mm/s, resulting in trench widths less than 10μm. Excessive power (>2.4 W) damages the glass substrate, while insufficient power (<1.8 W) leaves conductive residues that cause electrical shorts.

3.2 P2 Scribing: Multilayer Ablation with Precision

The P2 process is technically the most challenging as it must penetrate multiple functional layers (ETL/perovskite/HTL) without damaging the underlying TCO layer exposed during P1. Ultraviolet lasers (355 nm) are particularly effective due to their high absorption in perovskite layers and low absorption in TCO layers, enabling selective removal without substrate damage.

Optimal P2 parameters identified through research include average power of 119-189 mW, frequency of 80 kHz, and speed of 400 mm/s. Transmission spectroscopy reveals that at 150mW power, perovskite residue may remain after multiple scribes, while power ≥234mW reduces residue but risks ITO damage. The optimal window is therefore between 150-234mW at 80kHz and 400mm/s.

For fs-laser systems (532 nm wavelength, 300 fs pulse width), the optimal P2 parameters are 0.46 W power and 4000 mm/s speed, achieving a depth of 858 nm that completely removes the functional layers without ITO damage.

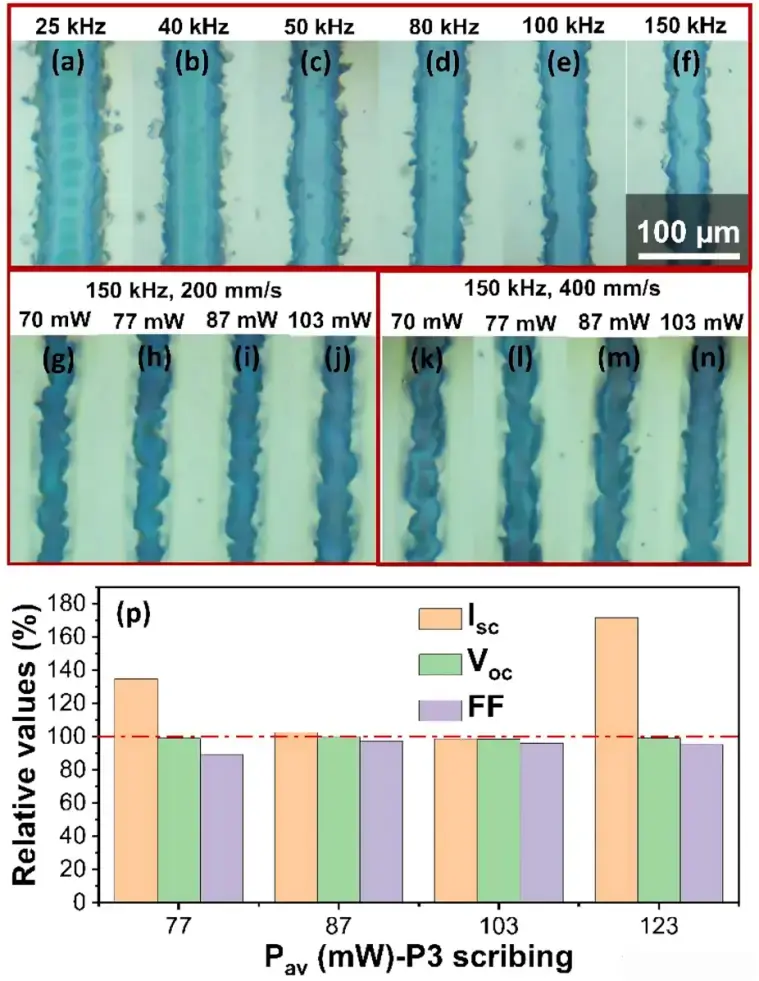

3.3 P3 Scribing: Electrode Isolation

The P3 process isolates the back electrode (typically 75nm gold) without damaging the underlying perovskite and charge transport layers. Research indicates that optimal parameters involve frequencies of 100-150 kHz and power approximately 100 mW, producing clear insulation channels.

With fs-laser systems, P3 scribing achieves optimal results at 0.2 W power and 6000 mm/s speed, creating a trench depth of 534 nm that slightly exceeds the metal layer thickness but avoids damage to the underlying P1 layer.

The effectiveness of P3 scribing is validated by comparing the relative performance parameters of sub-cells—successful scribing maintains nearly 100% of the original short-circuit current, open-circuit voltage, and fill factor values.

4 Laser Parameter Optimization for Different Substrates

4.1 Rigid vs. Flexible Substrates

The monitoring data reveals significant differences in optimal laser parameters for rigid and flexible substrates. For rigid glass substrates, higher power levels can be employed, but must be carefully controlled to avoid microcracks. For flexible PEN/ITO substrates, lower power settings are necessary to prevent substrate deformation, and additional mechanical cleaning processes may be required to address edge.

4.2 Wavelength Selection

Different laser wavelengths offer distinct advantages for various scribing applications. Ultraviolet lasers (355 nm) provide high material absorption and low thermal impact, making them suitable for all three scribing steps on both glass and flexible substrates. Fs-laser systems with 532 nm wavelength offer superior precision for multilayer ablation.

5 Integrated Quality Assurance Approach

An effective quality assurance strategy combines real-time monitoring with statistical process control. The implementation of automated imaging systems allows for 100% inspection of scribing quality, while electrical testing provides functional validation of the interconnection integrity.

Data collected from these monitoring systems can be used to build process control models that predict quality outcomes based on laser parameters, enabling proactive adjustments before defects occur. This integrated approach significantly improves production yield while reducing the need for manual inspection and rework.

Conclusion

The commercialization of perovskite solar modules depends critically on achieving high precision and reliability in the P1, P2, and P3 laser scribing processes. Through the implementation of advanced monitoring technologies including online imaging systems and automated electrical testing, combined with careful optimization of laser parameters for specific substrate types and layer structures, manufacturers can significantly improve scribing quality and production yield.

As the industry progresses toward GW-scale production, the integration of robust real-time monitoring and quality control systems will be essential for maintaining consistent performance and reliability in perovskite solar modules. The technical approaches outlined in this article provide a framework for achieving the high-precision manufacturing standards required for commercial success.