How Wearable Devices Get Power: Lecheng’s Roll-to-Round Laser Systems Enable Self-Powered Wearables

1. The Challenge of Powering Next-Generation Wearables

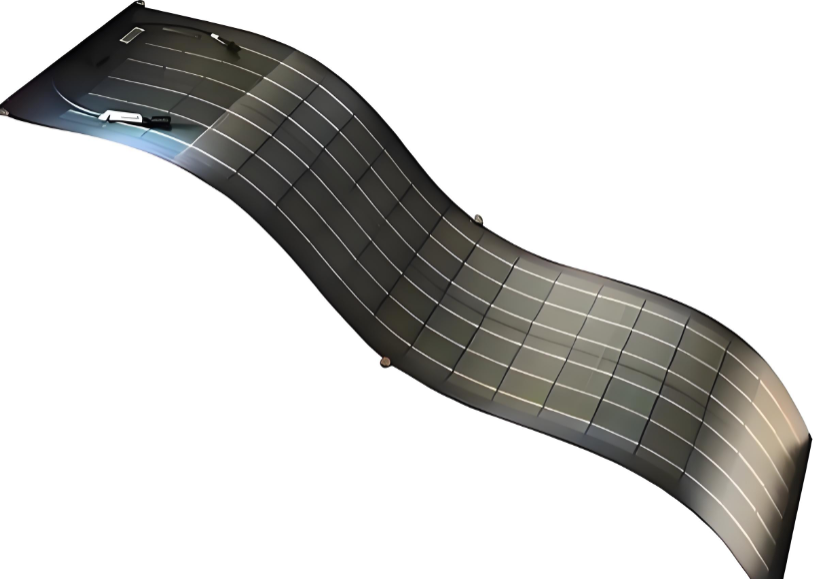

As wearable technology evolves from fitness trackers to smart medical patches and augmented reality glasses, traditional battery solutions face critical limitations. Rigid, bulky batteries compromise comfort and design flexibility, while frequent charging disrupts continuous health monitoring or data collection. This gap is driving demand for thin, flexible, and self-sustaining power sources—specifically, lightweight solar cells integrated directly into wearables. Lecheng Intelligent addresses this need with its roll-to-round laser processing systems, which manufacture bendable perovskite solar cells optimized for irregular surfaces. By using ultra-fast picosecond lasers (e.g., 355nm UV or 532nm green wavelengths), Lecheng’s equipment precisely scribes micro-circuits on flexible substrates without damaging heat-sensitive layers. The result: solar modules that curve around wrists, adhere to fabrics, or embed in eyewear, converting ambient light into reliable power.

2. Precision Laser Engineering: How Roll-to-Round Systems Work

Lecheng’s roll-to-round laser systems combine three core innovations to mass-produce wearable-compatible cells. First, the platform’s multi-beam splitting technology (supporting up to 12 parallel laser paths) simultaneously processes P1-P3 scribing and P4 edge-cleaning on a continuous film roll up to 500mm wide—dramatically accelerating production speed to 1.5 meters per minute. Second, proprietary focus-following sensors maintain laser beam accuracy even on uneven substrates, ensuring consistent scribe depths below 30μm and positional precision of ±10μm. This prevents micro-cracks or dead zones that reduce energy output. Third, the system’s closed-loop environmental control minimizes dust contamination during processing, critical for maintaining >95% yield in cleanroom-free settings. For wearable applications, Lecheng optimizes laser parameters to create cells with 15-18% efficiency under indoor light, enabling devices like ECG patches to operate indefinitely using ambient office lighting.

3. Real-World Applications: From Health Monitoring to Smart Textiles

The impact of Lecheng’s technology is already visible across industries. Medical wearables now integrate hair-thin perovskite cells to power continuous glucose monitors without battery replacements. In consumer electronics, smartwatches with laser-processed solar rings achieve 30% longer battery life under typical usage. Athletes benefit from self-powered biomechanical sensors woven into sportswear, while military gear uses flexible solar panels to recharge tactical equipment in the field. Looking ahead, Lecheng’s partnerships with textile manufacturers aim to embed laser-scribed cells directly into fabrics—enabling jackets that charge phones or tents that power IoT sensors during extended outdoor missions. By overcoming traditional power constraints, these innovations make wearables more autonomous, eco-friendly, and seamlessly integrated into daily life.

Conclusion

Lecheng Intelligent’s roll-to-round laser systems are revolutionizing how wearables harvest energy—transforming sunlight into a seamless power source that enhances device longevity, user convenience, and sustainability. By bridging high-precision manufacturing with real-world usability, they pave the way for a future where electronics are truly wireless and self-sufficient.