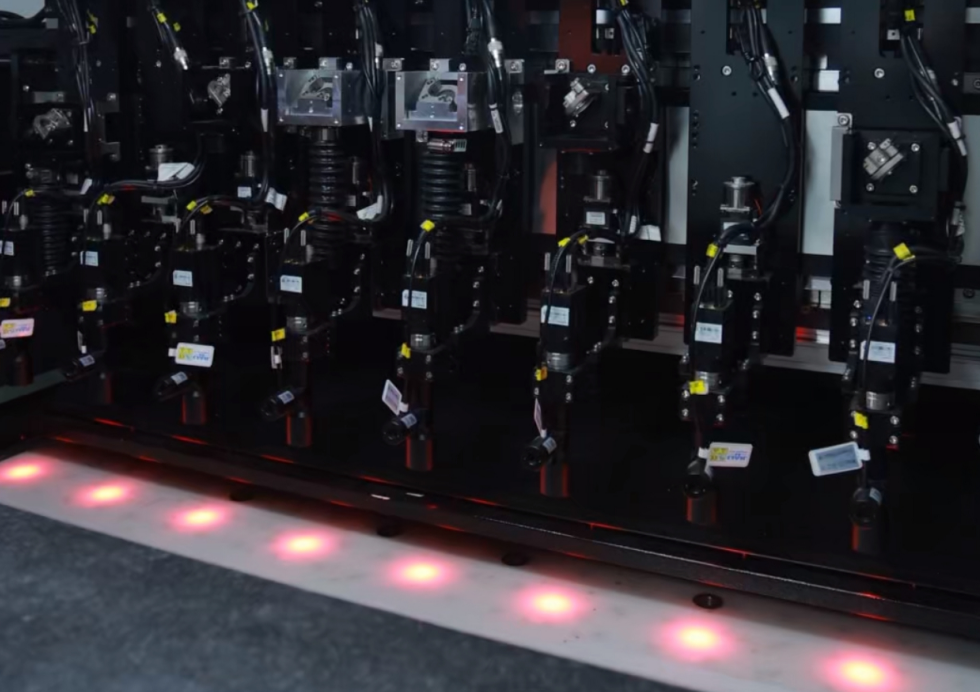

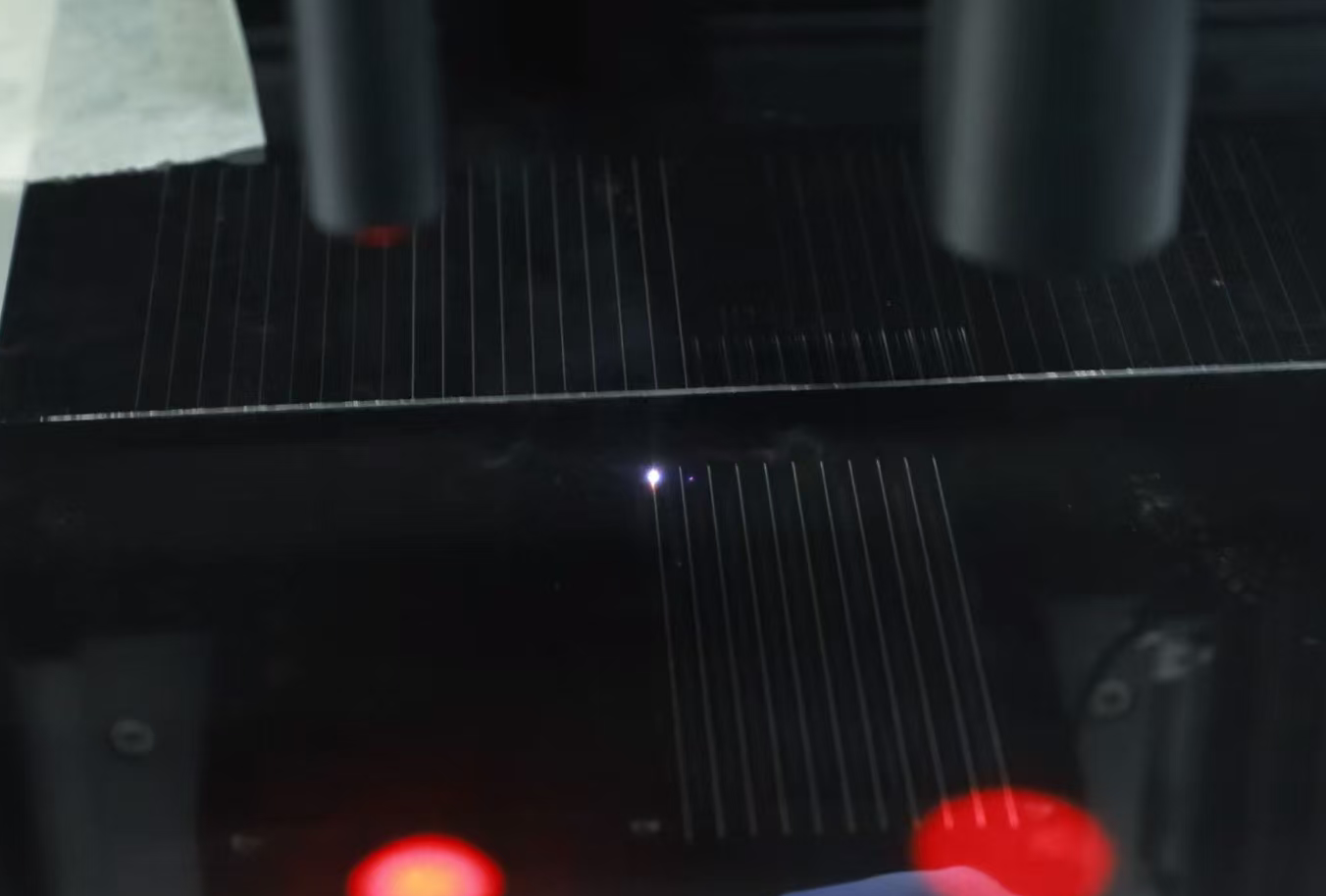

The rapid growth of flexible electronics—including flexible printed circuit boards (FPCs), organic light-emitting diodes (OLEDs), wearable sensors, and rollable displays—has driven demand for high-precision, high-throughput manufacturing solutions. Among these, the roll-to-roll (R2R) laser scribing & edge-cleaning systemhas emerged as a transformative technology, enabling non-contact, high-speed processingof thin, delicate materials.