Tsinghua Alumni He Le Leads Lecheng Intelligent in Advancing Laser Equipment Innovation

1. From Tsinghua Physics to Laser Industry Leadership

He Le's journey from Tsinghua University's prestigious physics program to founding Lecheng Intelligent represents a perfect fusion of academic excellence and industrial innovation. With a Bachelor's degree in Physics from Tsinghua and a Master's in Optical Engineering from Shanghai Jiao Tong University, He Le built upon eight years of practical experience at a listed laser company, where he led projects including FPC laser drilling and PERC battery scribing. This unique combination of theoretical knowledge and hands-on expertise enabled him to identify critical gaps in China's high-end laser equipment market. When he established Lecheng Intelligent in 2022, He Le positioned the company at the intersection of precision micro-nano laser equipment and emerging renewable energy applications—particularly perovskite solar cells and hydrogen fuel cells. His leadership has been instrumental in securing tens of millions in Series A funding from investors like Oriental Fenghai and Suzhou New District Venture Capital Group, validating the company's technological direction and market potential.

2. Building a Technological Ecosystem: Core Innovations and Strategic Vision

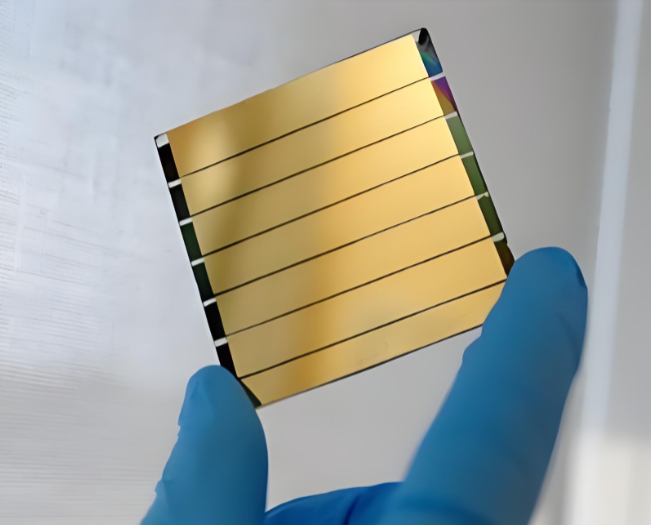

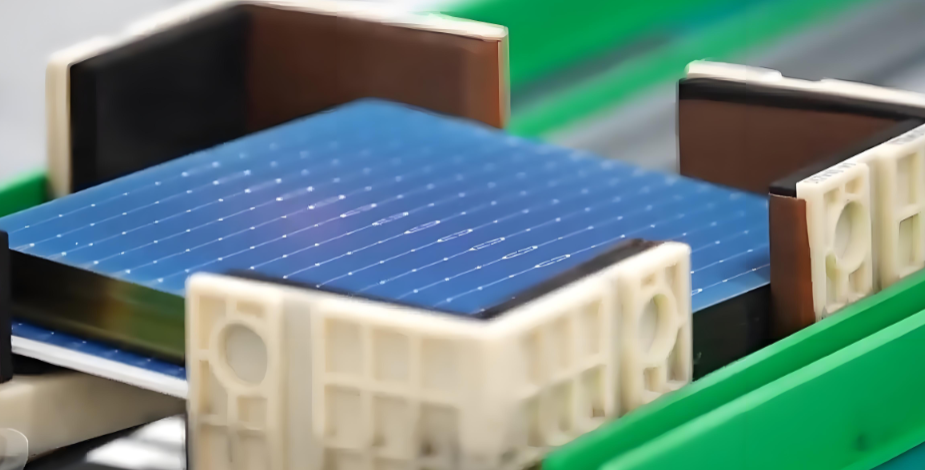

Under He Le's guidance, Lecheng Intelligent has developed a comprehensive technological ecosystem centered on three core pillars: optical capabilities, automation integration, and process customization. The company's optical expertise includes advanced beam splitting technology supporting up to 24 laser paths—a domestic industry benchmark—and dual-incident laser processing (glass side/film side) that adapts to diverse client requirements. In automation, Lecheng's proprietary focus-following and path-tracking systems maintain ±5μm precision across 2400×1200mm large-format processing, addressing critical challenges in perovskite cell dead zone reduction. He Le's strategic emphasis on collaborative R&D has led to partnerships with leading perovskite enterprises, where Lecheng's engineers work directly with client production lines to optimize laser parameters for specific material stacks. This hands-on approach has resulted in the successful delivery of laser equipment for four 100MW perovskite pilot lines, establishing Lecheng as a trusted solution provider in the emerging thin-film solar industry.

3. Empowering Industry Transformation: From Laboratory to Mass Production

He Le's vision extends beyond equipment manufacturing to enabling entire industry chains. By integrating Lecheng's laser systems with coating, PVD, and testing equipment from partner manufacturers, the company offers comprehensive perovskite production line solutions that accelerate technology commercialization. His background in project management (certified PMP) ensures rigorous execution: the 2500㎡ production base in Changshu Economic Development Zone achieves an annual capacity of 100 laser units while maintaining stringent quality control. Under his leadership, Lecheng has pioneered applications beyond solar—including hydrogen fuel cell bipolar plate welding with 0.08mm seam width precision, and FPC laser drilling with 50μm micro-vias—demonstrating the versatility of laser technology across clean energy sectors. He Le actively promotes industry standardization as Executive Secretary-General of the Perovskite Industry Branch of China International Science and Technology Promotion Association, positioning Lecheng as both a technology innovator and ecosystem builder.

Conclusion

He Le's Tsinghua-honed scientific rigor and industry experience have positioned Lecheng Intelligent at the forefront of laser equipment innovation. By bridging advanced research with market-driven applications, he is not only advancing China's high-end manufacturing capabilities but also accelerating the global transition to sustainable energy solutions.