The Future of R2R Processing

Intelligent Automation and Adaptive Control Systems

The future of roll-to-roll (R2R) processing lies in smart, self-optimizing systems that integrate real-time data analytics with advanced laser technologies. Lecheng is pioneering this transition with equipment featuring AI-driven vision systems and adaptive control algorithms. These systems continuously monitor web tension, substrate alignment, and laser parameters—automatically adjusting processing conditions to maintain micron-level accuracy at speeds exceeding 2 m/min. For example, Lecheng's R2R laser scribing platforms incorporate multi-sensor feedback loops that detect and correct substrate deformation or thermal drift without interrupting production. This level of intelligence minimizes manual intervention, reduces scrap rates by up to 25%, and enables uninterrupted 24/7 operation—critical for scaling perovskite and flexible electronics manufacturing.

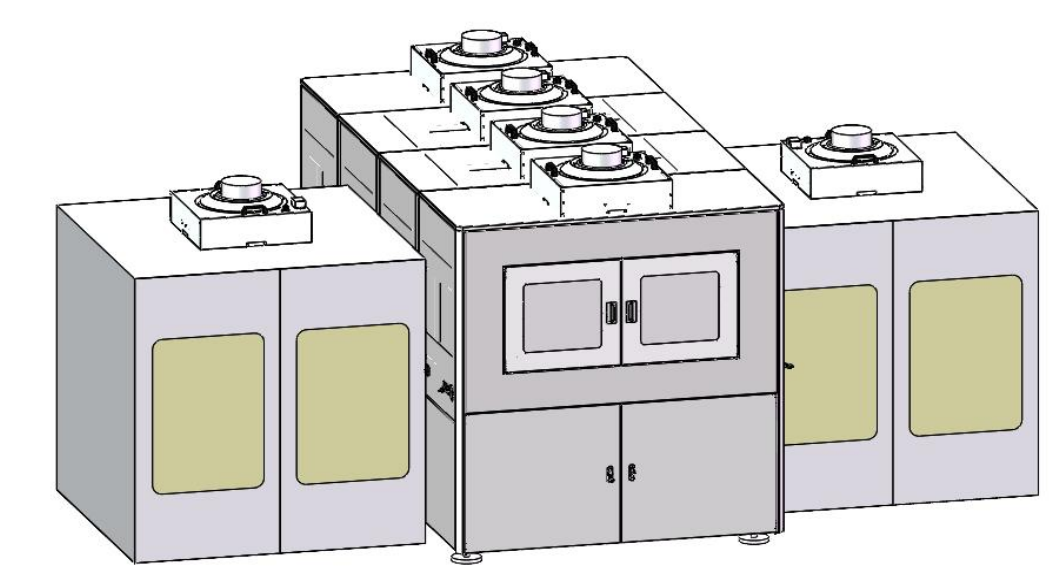

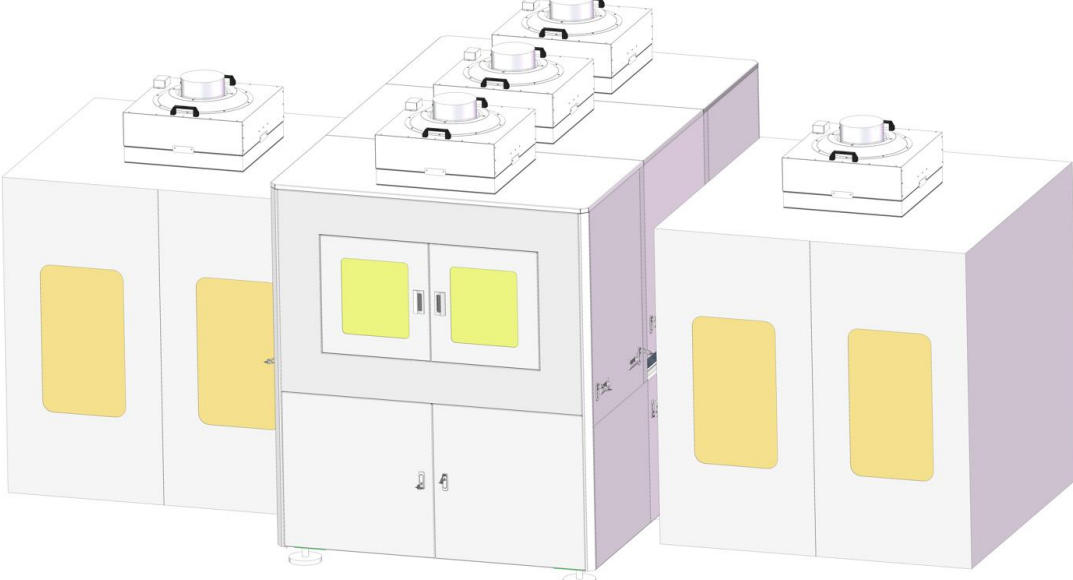

Multi-Functional Platforms for Hybrid Manufacturing

Next-generation R2R systems will evolve from single-process tools to integrated platforms capable of combining laser scribing, etching, cleaning, and inspection in a single pass. Lecheng's modular R2R architectures already demonstrate this trend, allowing manufacturers to configure customized processing sequences—such as P1-P4 patterning for perovskite cells followed by inline electroluminescence testing. The company's use of wavelength-agile lasers (e.g., UV, green, and IR sources) further enables multi-material processing, from ablating ITO layers on PET to patterning metal grids on flexible substrates. By consolidating multiple steps, these systems reduce footprint by 40% and cut energy consumption by 30%, while accelerating time-to-market for new products.

Sustainable and Scalable Production for Global Decarbonization

As global demand for green technology surges, R2R processing must align with sustainability goals while supporting rapid scalability. Lecheng addresses this dual challenge through energy-efficient laser sources (e.g., fiber lasers with >30% wall-plug efficiency) and dry, chemical-free processing that eliminates hazardous waste. The company’s R2R systems are designed for easy replication and deployment across distributed manufacturing hubs, enabling localized production of solar modules and flexible electronics. With compatibility for renewable-powered facilities and predictive maintenance features that extend equipment lifespan, Lecheng’s technology not only reduces carbon footprint but also lowers the Levelized Cost of Electricity (LCOE) for perovskite solar energy—projected to fall below $0.03/kWh by 2030.

The future of R2R processing is intelligent, integrated, and sustainable—and Lecheng is at the forefront of this transformation. By merging precision laser engineering with smart automation and eco-conscious design, the company is empowering manufacturers to achieve unprecedented efficiency and scalability in the green technology era.