Renshuo Perovskite's Commercial Modules Approach Silicon-Based Solar Cell Performance

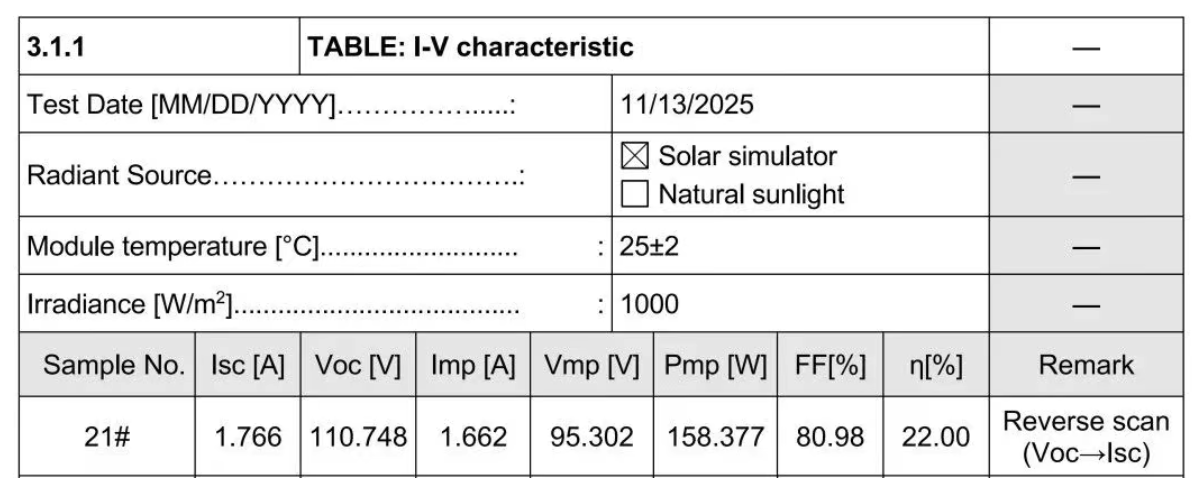

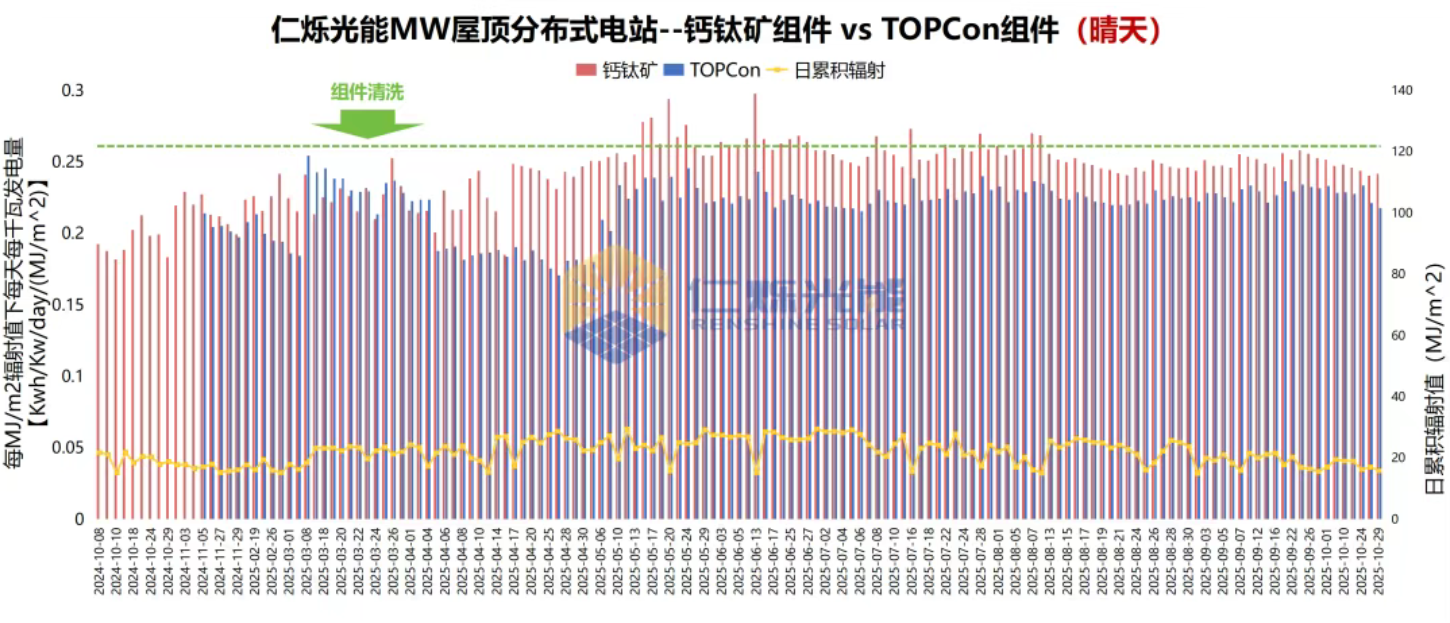

Thanks to superior weak-light performance and a low temperature coefficient, perovskite photovoltaics achieve over 10% higher actual power generation than silicon-based modules at the same rated conversion efficiency. Perovskite modules with 22% efficiency can match the actual power output of mainstream silicon-based modules such as TopCon (around 24% efficiency). While silicon technology is approaching its efficiency ceiling, perovskite still holds significant potential for improvement through ongoing formula innovations, reduced edge effects, and optimized production processes.Since the equipment integration of Renshuo Perovskite’s 150 MW pilot production line in early 2024, the company has systematically advanced multiple key technologies, including AI-enabled high-throughput formula R&D, controlled uniform crystallization, high-quality laser scribing, and novel encapsulation methods. In less than two years, the mass production efficiency of their square-meter-scale perovskite modules has achieved a leap from 15% to 22%, fully demonstrating Renshuo's global leadership in perovskite mass production technology.