Predictive Maintenance with IoT Sensors on Laser Equipment

Real-Time Monitoring for Enhanced Equipment Reliability

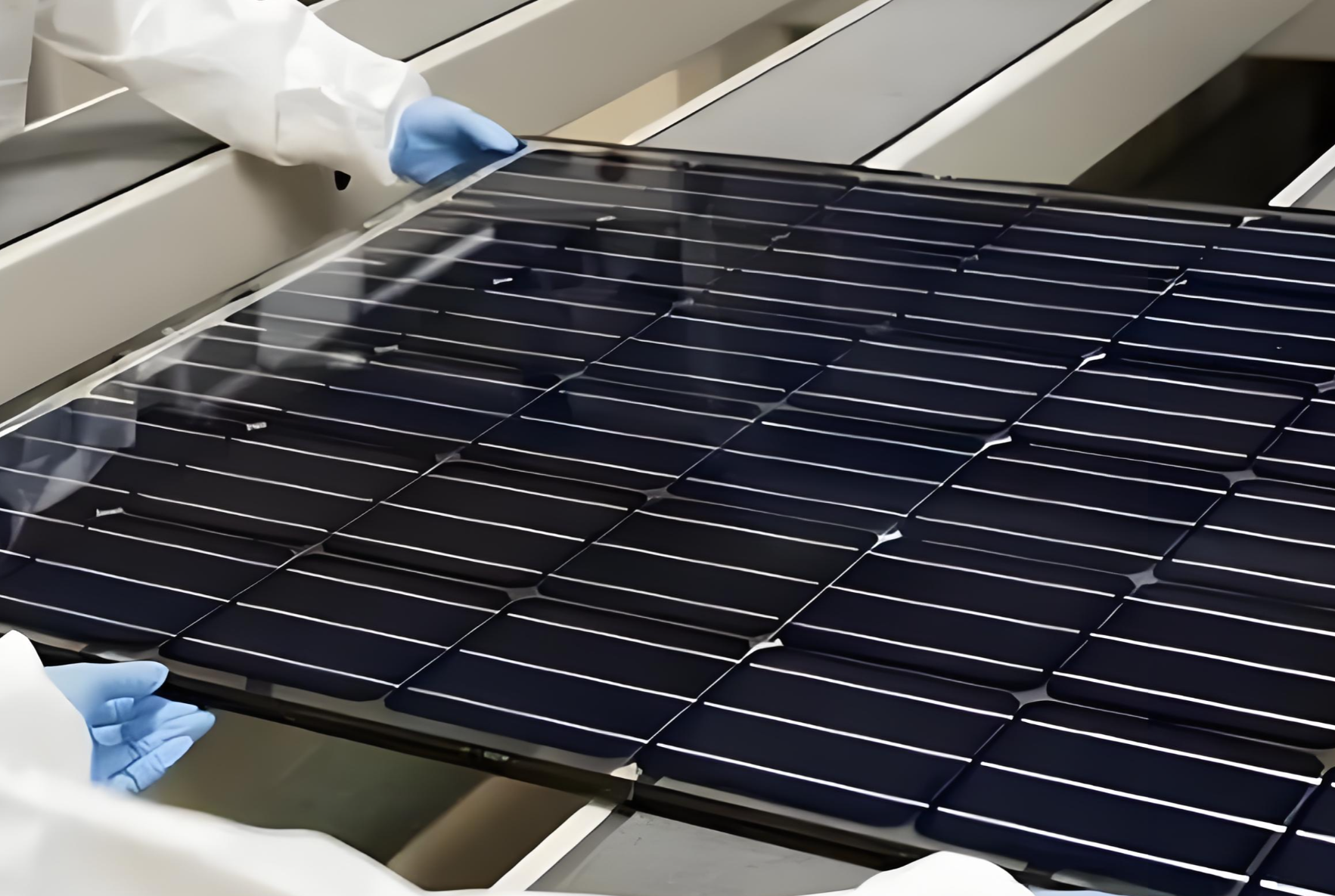

Lecheng integrates IoT sensors into their laser systems to monitor critical parameters such as laser power stability, cooling system performance, and galvanometer accuracy. These sensors collect data at millisecond intervals, enabling real-time detection of anomalies like power fluctuations or temperature deviations. For instance, in perovskite laser scribing equipment, IoT sensors track beam homogeneity and scanning speed, ensuring consistent P1-P3 patterning accuracy. By analyzing historical performance data, Lecheng's systems can predict component wear—such as laser source degradation or lens contamination—weeks before failure, reducing unplanned downtime by up to 40%. This proactive approach is vital for high-volume solar production lines where equipment reliability directly impacts yield.

Data-Driven Insights for Maintenance Optimization

The IoT platform aggregates operational data from multiple laser systems, applying machine learning algorithms to identify patterns correlated with failures. For example, vibration sensors on R2R (roll-to-roll) laser modules detect misalignments in substrate handling, while thermal cameras monitor heat accumulation during high-speed scribing. Maintenance alerts are prioritized based on severity, allowing technicians to address critical issues like mirror degradation or rail wear before they affect processing quality. Lecheng's cloud-based dashboard provides fleet-wide analytics, helping manufacturers optimize maintenance schedules and reduce spare parts inventory costs by 25%. This data-driven strategy is particularly valuable for distributed production facilities, enabling centralized oversight of laser equipment across global sites.

Integration with Smart Manufacturing Ecosystems

Lecheng's IoT-enabled lasers seamlessly connect with factory MES (Manufacturing Execution Systems) and ERP platforms, creating a closed-loop smart manufacturing environment. Predictive maintenance data triggers automated work orders, while performance metrics are cross-referenced with production outcomes—such as dead zone width in perovskite modules—to refine process parameters. Remote diagnostics allow Lecheng’s engineers to troubleshoot issues virtually, reducing on-site service visits by 60%. For high-precision applications like laser welding or glass cutting, IoT data validates equipment calibration against ISO standards, ensuring consistent quality in sectors like aerospace and medical devices.

Lecheng's IoT-powered predictive maintenance transforms laser equipment from isolated tools into interconnected assets, maximizing uptime and precision while minimizing operational costs. This innovation strengthens their role as a leader in smart manufacturing solutions for the renewable energy sector.