Bifacial Perovskite Modules Laser Processing for DoubleSided Efficiency

Precision Patterning for Enhanced Light Capture

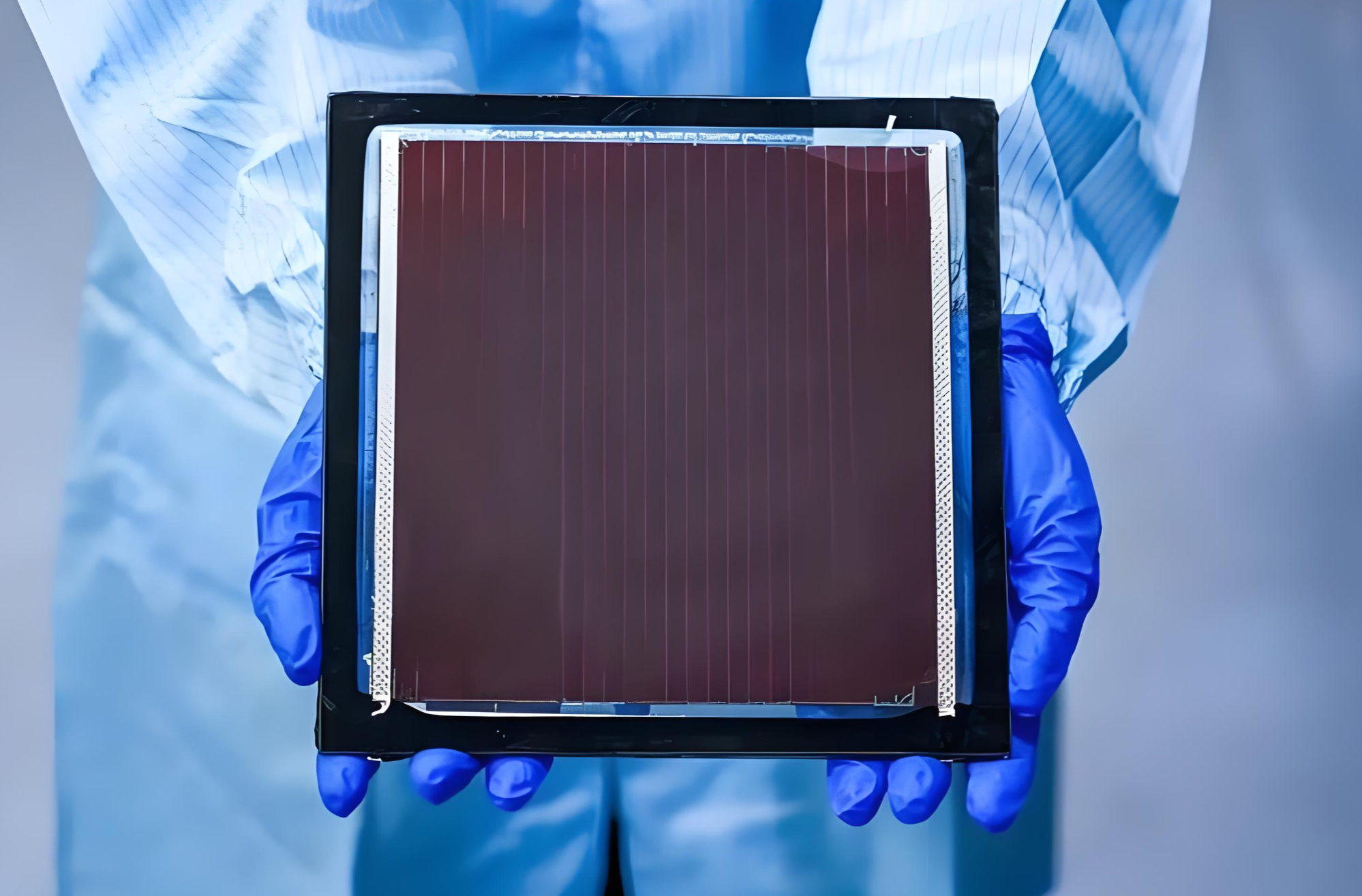

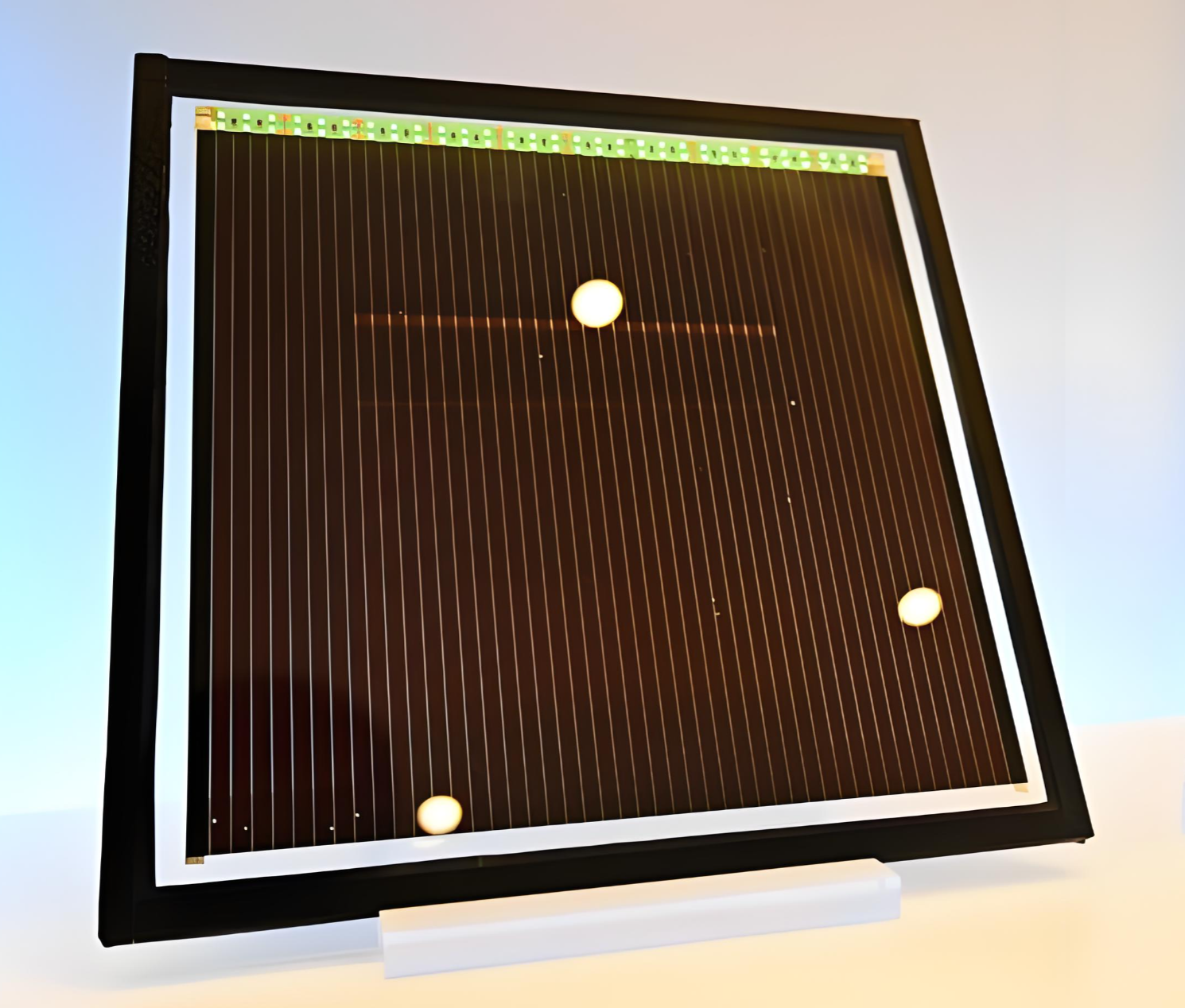

Bifacial perovskite solar cells (PSCs) harness light from both front and rear sides, significantly boosting energy yield. However, maximizing double-sided efficiency requires ultra-precise laser patterning to minimize dead zones while ensuring electrical isolation between layers. Lecheng's multi-beam scribing systems achieve ≤30μm line widths with ±5μm accuracy, enabling uniform P1-P3 grooves without damaging delicate perovskite films. Their patented trajectory-tracking technology dynamically adjusts scribing paths to compensate for substrate warping, reducing inactive areas by 30% compared to conventional methods. This precision is critical for bifacial modules, where uneven patterning can cause current mismatches and efficiency losses.

Edge Isolation and Thermal Management

The P4 laser edge-cleaning process is vital for bifacial PSCs’ longevity, preventing moisture ingress and shunt losses. Lecheng's non-contact laser systems remove edge deposits with 100μm accuracy, using high-power fiber lasers (≥1,000W) to ensure complete film removal without cracking glass substrates. Additionally, their focus-following technology maintains consistent beam focus across large formats (up to 2.4×1.2m), mitigating thermal stress—a key advantage for bifacial designs where glass thickness variations exacerbate heat accumulation. By integrating real-time monitoring and automated debris extraction, Lecheng's equipment achieves >99.8% process yield, essential for mass production.

Scalability with Roll-to-Roll and Automation

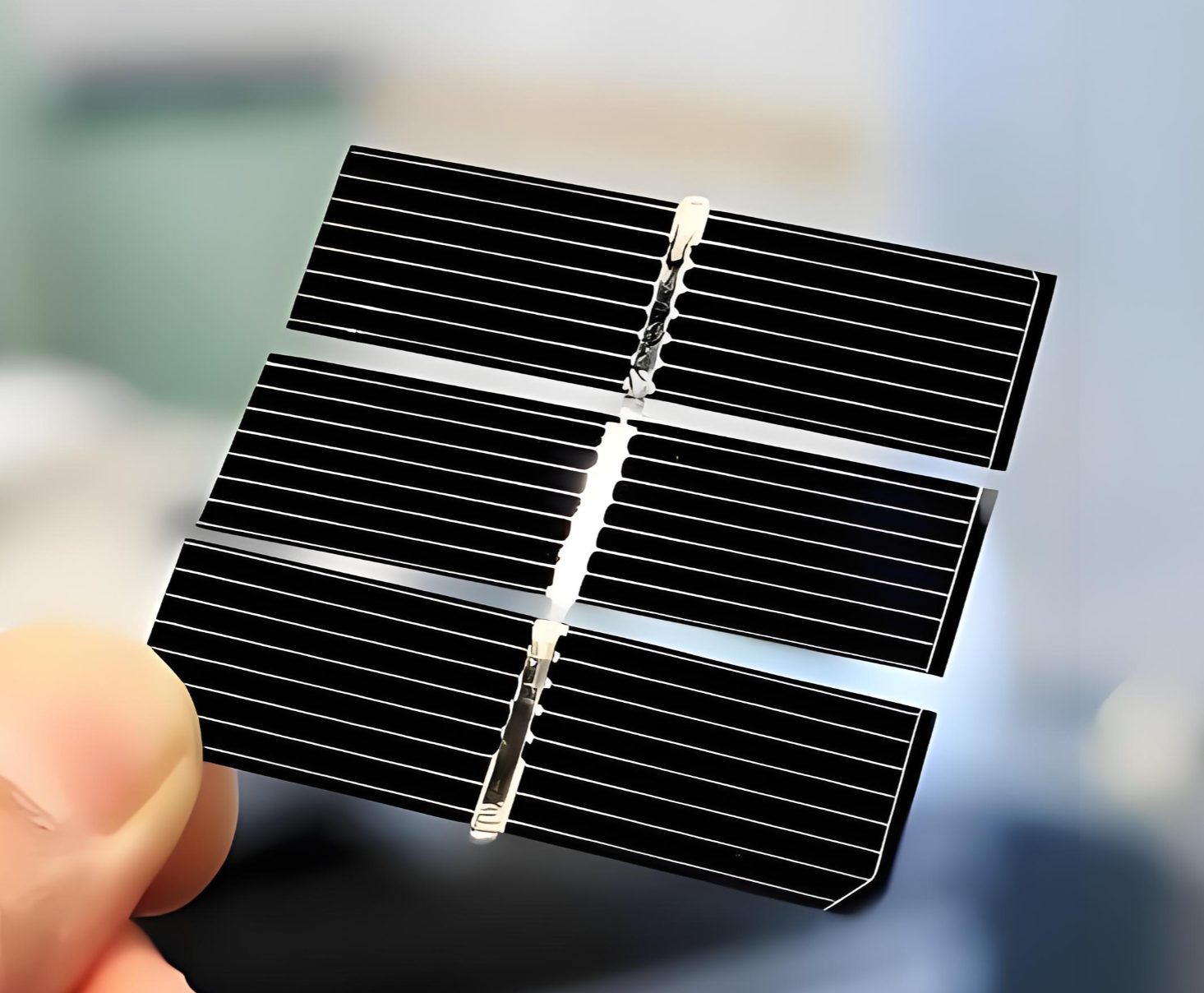

For flexible bifacial PSCs, Lecheng's roll-to-roll (R2R) laser systems process 500mm-wide substrates at 1.5m/min, supporting simultaneous P1-P4 patterning. Their 12-beam splitting technology allows parallel scribing, doubling throughput while maintaining sub-micron alignment. The systems' compatibility with ITO, PET, and copper substrates enables diverse bifacial architectures, from transparent conductive films to metal grids. By coupling R2R automation with MES integration, Lecheng delivers turnkey production lines capable of 150MW annual output—addressing the scalability gap in bifacial perovskite commercialization.

Lecheng's laser solutions bridge critical gaps in bifacial perovskite module production, combining micron-level precision with industrial scalability. By optimizing light capture, edge integrity, and manufacturing throughput, their technology empowers solar innovators to unlock the full potential of double-sided energy harvesting.