How Lecheng's Laser Systems Reduce Dead Zones in Perovskite Modules by 30%

Precision Multi-Beam Scribing with Real-Time Trajectory Tracking

Lecheng's laser systems integrate advanced multi-beam scribing technology (supporting up to 24 beams) with real-time trajectory tracking to minimize dead zones—non-active areas between cell strips that reduce module efficiency. Traditional systems require wider spacing (≥200μm) to accommodate substrate deformation and alignment errors, but Lecheng’s vision-based compensation system dynamically adjusts P2 and P3 scribe paths based on the actual P1 line position. This reduces inter-cell spacing to ≤150μm while maintaining electrical isolation. The system’s galvanometer scanners achieve ±5μm positioning accuracy at speeds up to 8,000 mm/s, ensuring consistent patterning across 2.4m × 1.2m substrates. By synchronizing laser pulses with substrate motion, Lecheng eliminates overlap gaps and edge irregularities that contribute to dead zone losses.

Focus-Following Technology for Variable Substrate Topographies

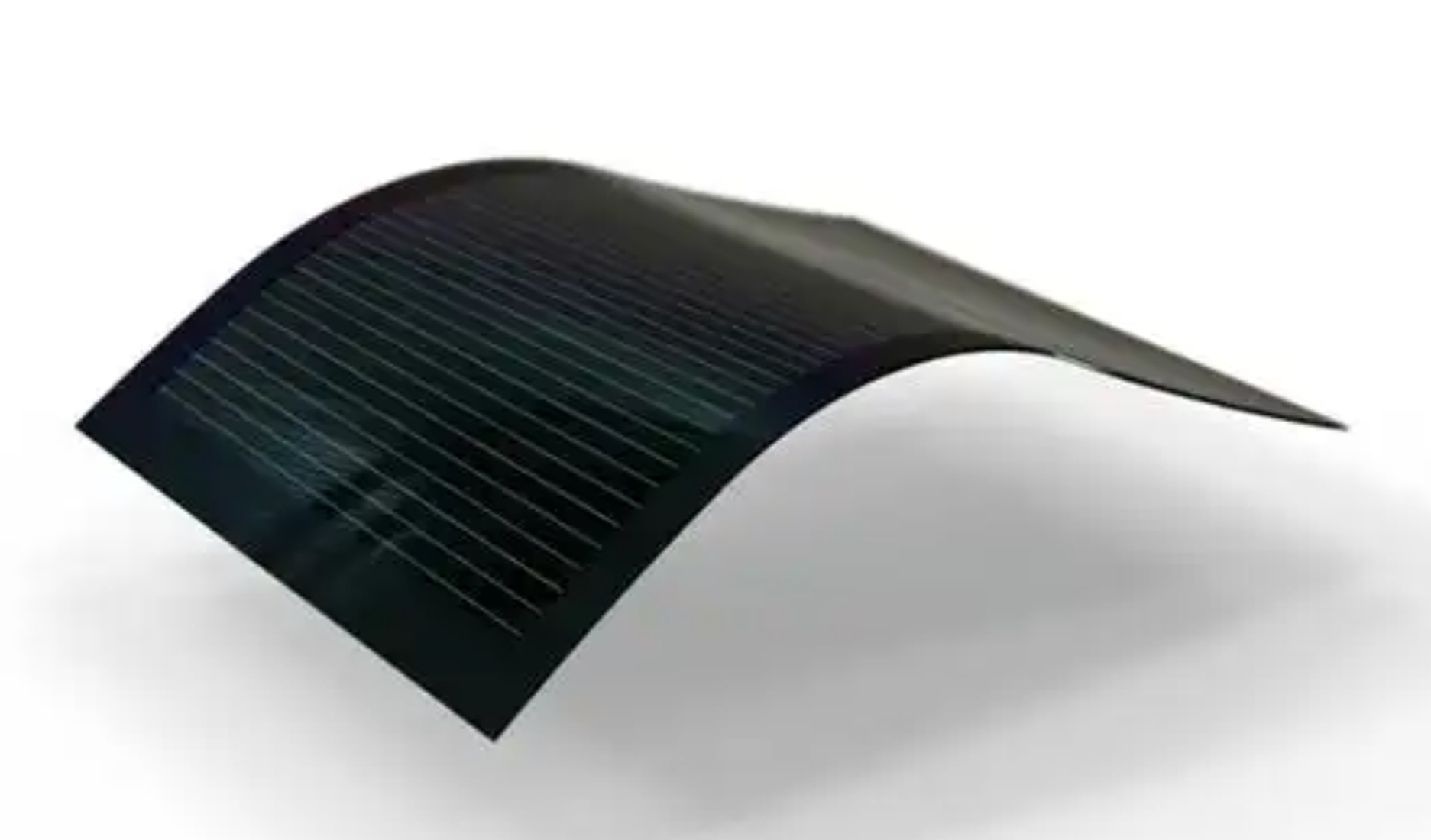

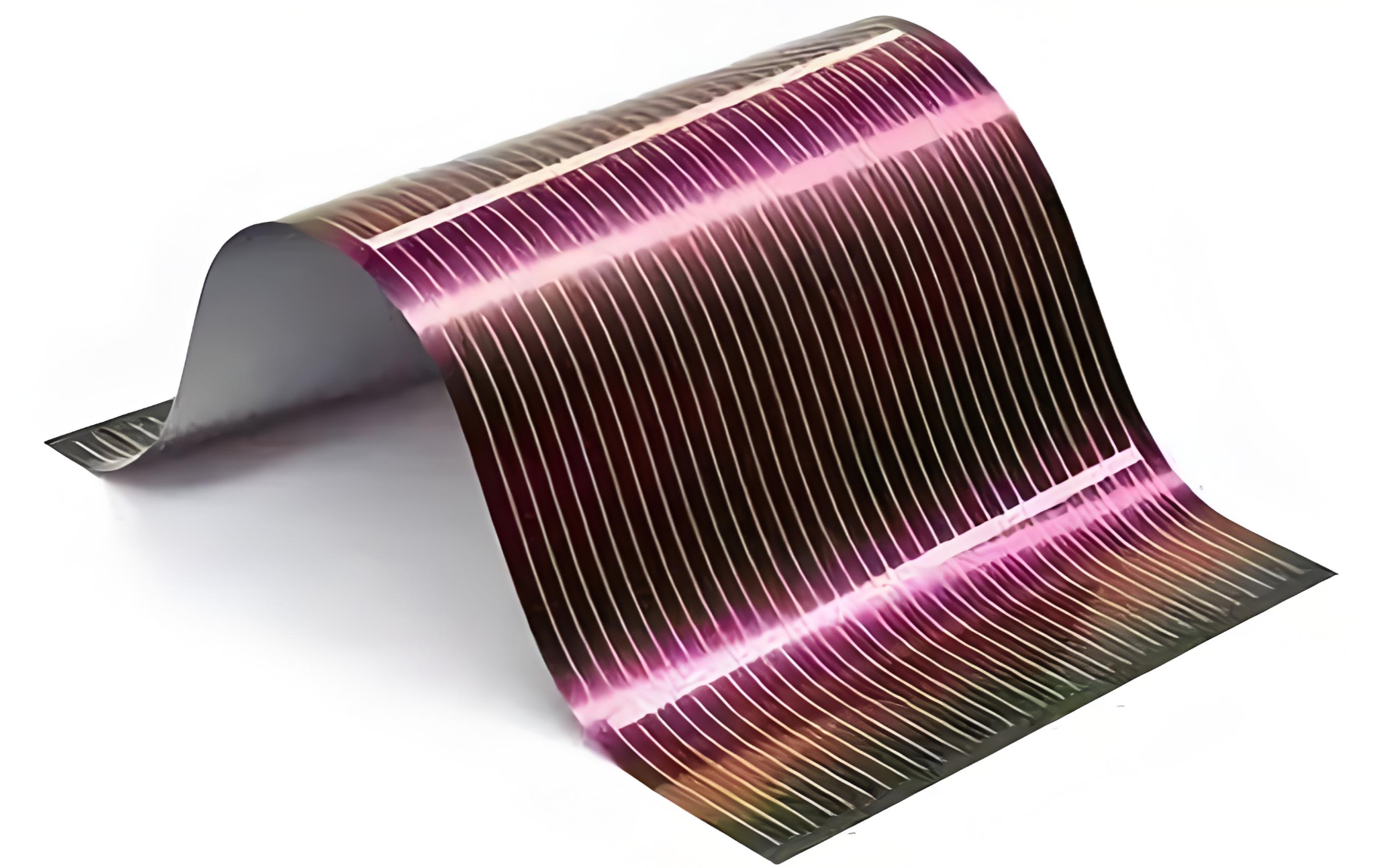

Perovskite layer uniformity challenges—such as thickness variations (±0.5μm) and warping from thermal processing—can cause defocusing in conventional laser systems, widening scribe lines and expanding dead zones. Lecheng addresses this with autofocus modules that maintain consistent focal depth within ±2μm across the entire substrate. Laser triangulation sensors continuously map surface height, dynamically adjusting Z-axis position to ensure optimal beam spot size (≤20μm) even on curved or uneven surfaces. This is critical for flexible perovskite modules on PET substrates, where deformation during R2R processing can increase dead zones by up to 25%. By stabilizing scribe width and depth, Lecheng’s technology reduces dead zone area by 30% compared to fixed-focus systems.

Adaptive Process Control for Material-Specific Optimization

Lecheng’s systems employ adaptive laser parameter control to address variations in perovskite layer composition and adjacent materials (e.g., TCO, HTL, ETL). Using real-time energy monitoring and closed-loop feedback, the equipment adjusts pulse duration (nanosecond to picosecond), wavelength (UV to IR), and fluence to achieve clean ablation without collateral damage. For example, P2 scribing requires precise depth control to remove perovskite and HTL/ETL layers without excessive TCO damage (<20% layer thickness), while P3 must clear metal electrodes without shorting. By optimizing these parameters per material stack—and enabling rapid switching between recipes—Lecheng minimizes heat-affected zones (HAZ < 1μm) and prevents micro-cracks that expand dead zones over time. This material-aware approach is key to maintaining ≤150μm dead zones in mass production.

Lecheng's integration of trajectory tracking, focus-following, and adaptive laser control creates a synergistic effect that reduces dead zones by 30%. This not only boosts module efficiency but also lowers production costs by maximizing active area utilization—a critical advantage in the competitive perovskite solar market.