1. Introduction

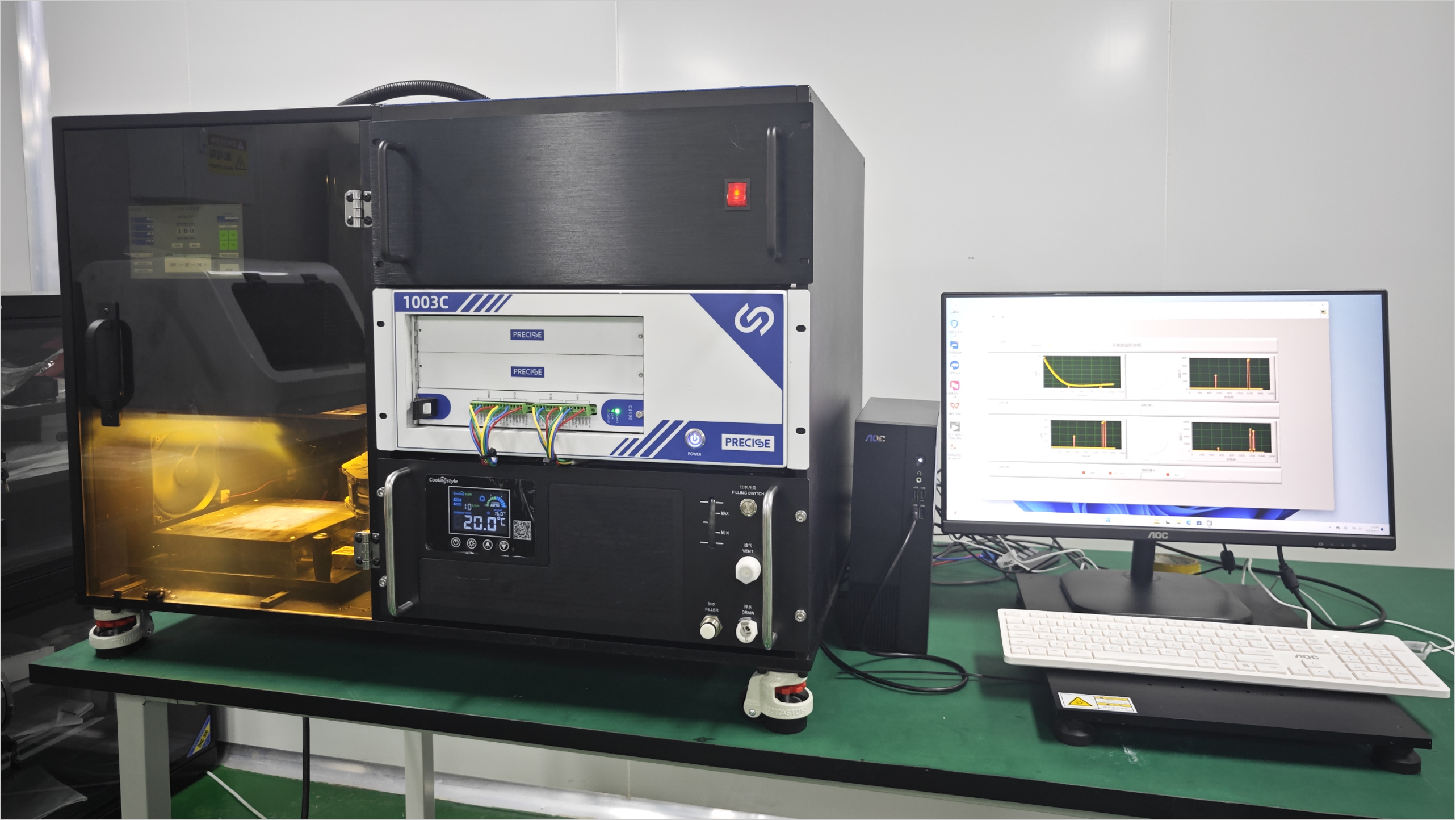

The Multichannel Photovoltaic (PV) Module Steady-State Testing System series (MCT series) is an advanced high-throughput platform designed for evaluating the performance and stability of perovskite, tandem, and crystalline silicon PV modules. By integrating optical, electrical, thermal, and software technologies, the system enables simultaneous testing of multiple modules under controlled conditions, accelerating R&D and quality control processes.

2. Core Technologies

2.1 Multidisciplinary Integration

The system combines expertise in optics, electronics, temperature control, and software algorithms to deliver comprehensive testing solutions. Key components include:

Steady-State Light Source:

Equipped with a Class 3A LED steady-state simulator (300–1200 nm spectrum, AM1.5G spectral match), offering a light spot uniformity of ≤2% and adjustable power density (100–1100 W/m²).

Multichannel Electrical Testing Unit:

Supports forward/reverse I-V scanning, 9-point fitting, and dynamic I-V testing with high precision (0.1% voltage/current accuracy).

Independent Temperature Control Modules:

Each channel maintains temperatures between 20–100°C with ±2°C stability, ensuring consistent testing conditions.

Software System:

2.2 Dynamic Testing Algorithms

The system employs advanced MPPT tracking and dynamic I-V testing to accurately characterize module performance under varying conditions, ensuring reliable data for material and process optimization.

3. Product Series and Specifications

The MCT series offers flexible configurations to accommodate diverse testing needs:

Model | MCTA-100-4T | MCTA-300-25T |

|---|---|---|

Channels | 4 channels (supports 8-point cycling) | 25 channels (switchable between single/25-channel modes) |

Sample Size | 20×20 mm to 50×50 mm | 50×50 mm to 250×250 mm |

Light Area | 100×100 mm / 250×250 mm (optional) | 300×300 mm |

Current Range | 0.5A/1A | Up to 25A (compatible with large modules) |

Temperature Control | ±2°C, 20–100°C | ±2°C, 20–100°C |

Modular Design: Compatible with glass/flexible substrates, supporting samples from 25×25 mm to 250×250 mm.

High-Throughput Testing:

Enables parallel testing of 4 or 25 modules without cross-interference.

4. Key Differentiators

High-Throughput Flexibility:

Configurations from 4 to 25 channels allow simultaneous testing of multiple modules, drastically reducing R&D cycles.

Precision Temperature Control:

Maintains ±2°C stability across a 20–100°C range, critical for reliability validation.

Spectral Adaptability:

Class 3A LED光源 with AM1.5G spectral matching ensures accurate simulation of real-world conditions.

Broad Compatibility:

Supports rigid/flexible substrates and sizes from mini-cells to large modules.

5. Application Scenarios

Production Line Quality Control: Rapid screening of process defects in manufacturing.

Component Reliability Validation: Degradation analysis under high temperature/humidity.

Perovskite Material Development: Long-term light stability testing for durability studies.

Tandem Cell R&D: Parallel testing accelerates optimization of layer-specific processes.

6. Conclusion

The MCT series provides a robust, scalable solution for high-throughput PV testing, combining precision hardware with intelligent software. Its modularity and customization capabilities make it ideal for research institutions and industrial labs focused on next-generation photovoltaic technologies.

Google Trending Core Keywords

Photovoltaic module testing

Perovskite solar cell stability

High-throughput PV characterization

MPPT algorithm for solar cells

Multichannel temperature control system

I-V curve testing equipment

Steady-state solar simulator

PV reliability assessment

Calcium titanium ore material testing