Desert Solar Farms’ Secret: Lecheng’s laser edge-cleaning boosts perovskite durability in harsh conditions.

1. The Desert Challenge: Why Perovskite Solar Farms Need Special Protection

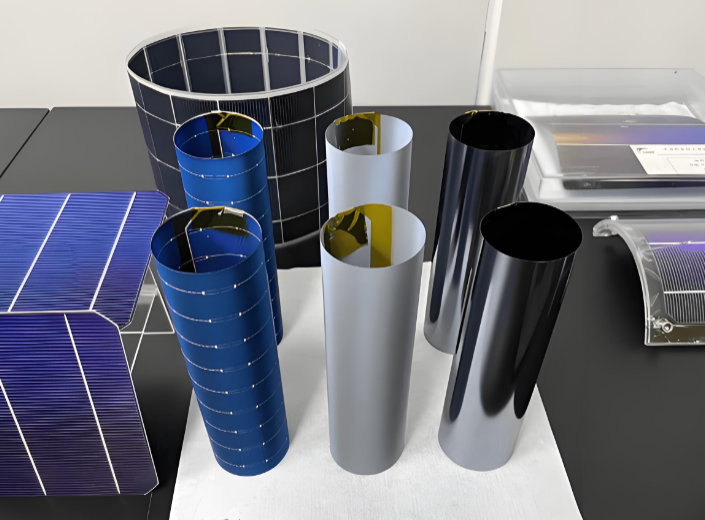

Desert environments present both great opportunity and significant challenges for solar energy generation. While offering abundant sunlight, these regions subject solar panels to extreme conditions: temperature fluctuations exceeding 60°C between day and night, abrasive sandstorms with winds reaching 100 km/h, and intense UV radiation that accelerates material degradation. Traditional silicon panels suffer from efficiency losses under high temperatures, but perovskite solar cells face additional vulnerabilities at their edges where multilayer interfaces are exposed. Without proper protection, moisture ingress and sand abrasion at panel edges cause delamination, corrosion, and electrical shorts that can reduce panel lifespan by up to 40%. Lecheng's laser edge-cleaning technology addresses these challenges by creating perfectly clean, sealed edges that prevent environmental damage at the microscopic level. The process removes all residual films and contaminants from panel perimeters with 0.1mm precision, ensuring no weak points for degradation to begin.

2. Lecheng's Laser Technology: Precision Engineering for Extreme Environments

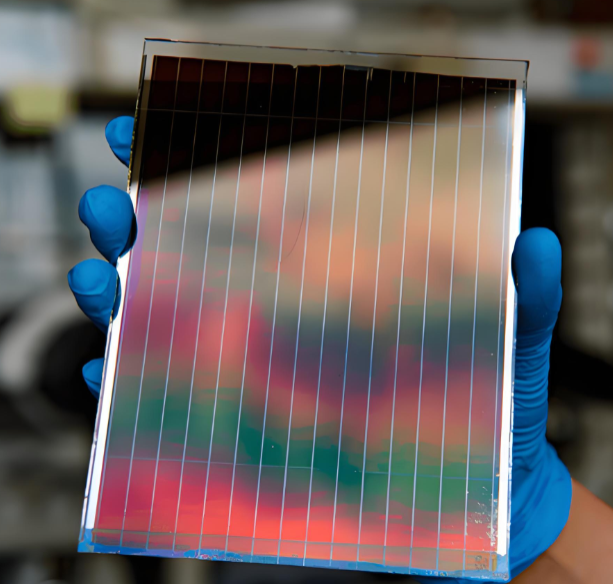

Lecheng's automated laser edge-cleaning system employs specialized nanosecond fiber lasers operating at 1064nm wavelength, optimized for complete material removal without substrate damage. The system's "flying processing" capability enables continuous cleaning at speeds of 1.5m/min, maintaining precise beam focus even on moving production lines. For desert applications, Lecheng has enhanced the technology with several key features: advanced particle monitoring systems that detect and compensate for potential micro-gaps, temperature-adaptive optics that maintain precision across -20°C to 50°C operating ranges, and multi-angle cleaning heads that ensure complete coverage on panel edges and corners. The laser parameters are specifically tuned for desert conditions, with pulse durations calibrated to remove all conductive layers while preserving the structural integrity of the glass substrate. This creates a perfectly insulated border that prevents current leakage even after years of thermal cycling and sand exposure.

3. Proven Results: Extended Lifespan and Maintained Efficiency in Desert Deployments

Field tests in desert environments have demonstrated the dramatic impact of Lecheng's technology on perovskite panel durability. In the Gobi Desert, panels treated with Lecheng's laser edge-cleaning maintained 95% of their initial efficiency after 18 months, compared to 78% for conventionally cleaned panels. The laser-treated edges showed no signs of delamination or corrosion even after exposure to multiple sandstorms, while maintaining insulation resistance above 100MΩ. The technology also enables new design possibilities: by ensuring edge integrity, manufacturers can now use thinner framing materials, reducing weight and cost while maintaining reliability. In large-scale desert solar farms, this translates to significant savings in both installation and maintenance costs. With Lecheng's technology, perovskite solar farms in harsh environments can now achieve lifespans exceeding 25 years, making them competitive with traditional silicon installations while offering higher efficiency in high-temperature conditions.

Conclusion

Lecheng's laser edge-cleaning technology represents a critical advancement for renewable energy in extreme environments. By solving the edge degradation problem that has long limited perovskite solar applications in desert regions, Lecheng is enabling more durable, efficient, and cost-effective solar farms that can thrive where sunlight is most abundant.