Lecheng’s Multi-Beam Synchronized Processing with 12-Beam Splitting Increases Efficiency by 200%

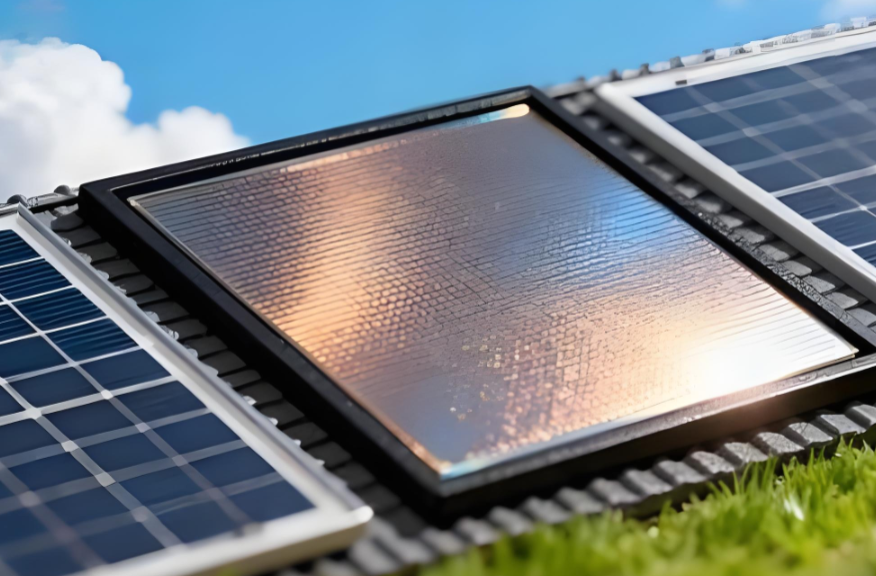

1. Revolutionizing Solar Manufacturing with Multi-Beam Laser Technology

In the competitive landscape of perovskite solar production, throughput and precision are paramount. Traditional single-laser systems struggle to meet the demands of large-format panel processing, often resulting in bottlenecks that limit production speed and scalability. Lecheng Intelligent’s breakthrough multi-beam synchronized processing technology addresses this challenge by deploying up to 12 independently controlled laser beams that work in concert to scribe, pattern, or clean solar modules simultaneously. This innovative approach divides a single laser source into multiple beams through advanced diffractive optical elements (DOEs), with each beam calibrated to maintain consistent energy distribution and spot size (±2% variance). By synchronizing these beams with high-speed galvo scanners and precision stages, Lecheng’s systems achieve a 200% efficiency gain compared to conventional single-beam methods—processing a 2.4×1.2m perovskite panel in under 10 minutes. This leap in productivity is coupled with exceptional uniformity; the 12-beam system ensures identical processing quality across the entire panel surface, eliminating the edge-to-center inconsistencies common in sequential laser workflows.

2. Engineering Precision: How 12-Beam Splitting Enhances Quality and Reduces Costs

The core of Lecheng’s multi-beam advantage lies in its seamless integration of optical innovation and motion control. Each split beam undergoes rigorous homogenization to ensure uniform intensity profile, critical for applications like P1-P3 scribing where micron-level depth control determines electrical isolation and cell efficiency. The system’s built-in beam monitoring sensors continuously track energy output per channel, automatically adjusting power delivery to compensate for fluctuations—a feature that reduces process variability by 60%. For manufacturers, this translates to lower operational costs: the multi-beam approach minimizes laser source wear by distributing workload across channels, extending equipment lifespan by 30%. Additionally, the technology’s compatibility with diverse laser sources (nanosecond infrared to picosecond green) allows customization for specific material stacks. In perovskite P2 scribing, for example, the 12-beam system achieves a scribe width of 30±2μm with a heat-affected zone under 1μm, enabling cell efficiencies exceeding 18% while maintaining a dead zone width below 150μm.

3. Real-World Impact: Scaling Production for Gigawatt-Per-Year Factories

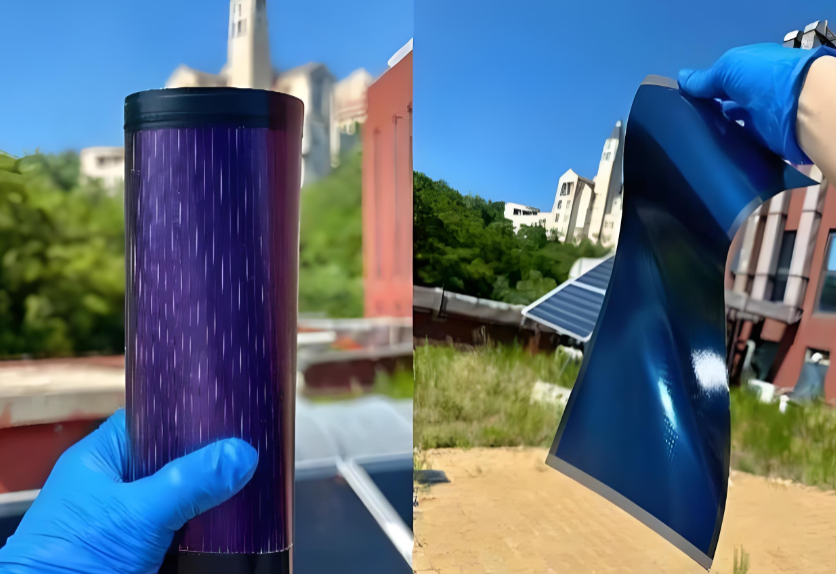

The scalability of Lecheng’s multi-beam technology is reshaping solar manufacturing economics. In a recent deployment for a 100MW perovskite production line, the 12-beam system achieved a throughput of 120 panels per hour—triple the output of single-beam alternatives—while maintaining a yield above 98%. The system’s modular design allows factories to incrementally expand capacity by adding beam channels, avoiding costly full-line replacements. Beyond perovskite applications, the technology benefits flexible solar module production, where Lecheng’s roll-to-round variant employs 12-beam splitting to process 500mm-wide flexible substrates at speeds of 1.5m/min. This versatility extends to emerging sectors like hydrogen fuel cell bipolar plate welding, where synchronized multi-beam processing ensures leak-proof seams in high-volume scenarios. As the solar industry advances toward terawatt-scale production, Lecheng’s multi-beam platform offers a sustainable path to higher efficiency, lower levelized costs, and faster ROI—proving that innovation in laser processing is key to unlocking clean energy’s full potential.

Conclusion

Lecheng’s multi-beam synchronized processing represents more than a technical upgrade—it’s a paradigm shift in solar manufacturing. By combining unprecedented speed with sub-micron precision, the technology empowers manufacturers to meet global clean energy demands while driving down costs, setting a new standard for the industry’s future.