How Lasers "Carve" Green Energy? Lecheng’s laser scribing turns glass into efficient solar panels for rooftop power generation.

1. The Art of Transforming Ordinary Glass into Solar Energy Generators

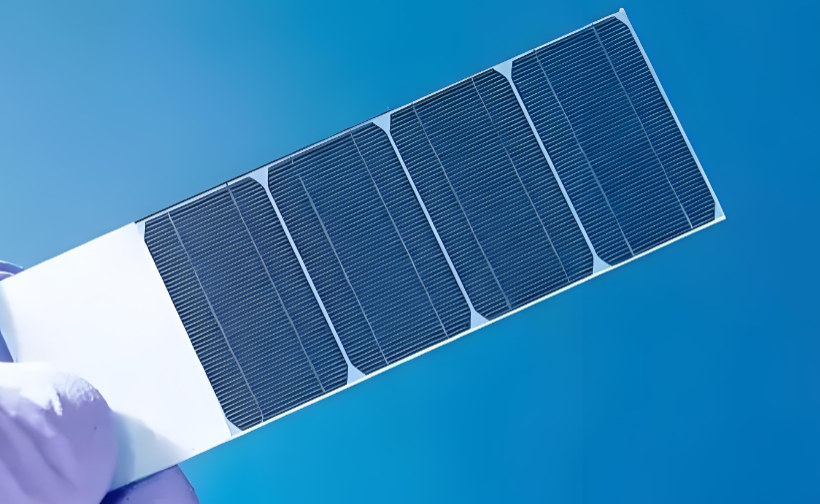

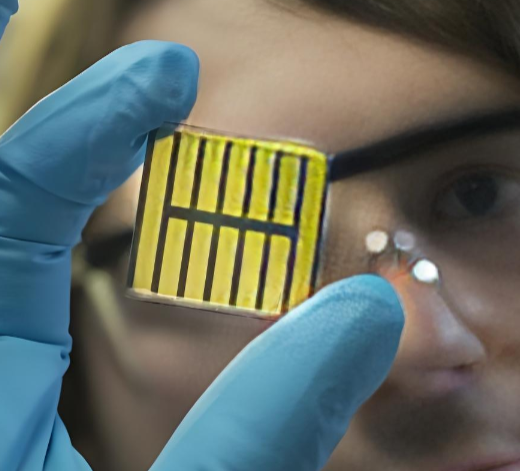

The journey from raw glass to high-efficiency solar panels begins with precision laser scribing—a process where lasers meticulously "carve" intricate electrical circuits onto glass substrates. Lecheng Intelligent has mastered this technology through its advanced laser systems capable of processing large-format glass up to 2.4×1.2 meters, the standard size for modern rooftop solar installations. Using ultra-short pulse lasers (picosecond and femtosecond), Lecheng's equipment removes thin-film layers with micron-level accuracy, creating the necessary P1, P2, and P3 patterns that define individual solar cells on a single panel. This process transforms passive glass into an active energy-harvesting surface, enabling sunlight to be converted into electricity through the photovoltaic effect. The precision of Lecheng's laser scribing ensures minimal material waste and maximum active area utilization, directly contributing to higher power output per panel—a critical factor for rooftop applications where space is often limited.

2. The Science Behind High-Efficiency Rooftop Solar Panel Manufacturing

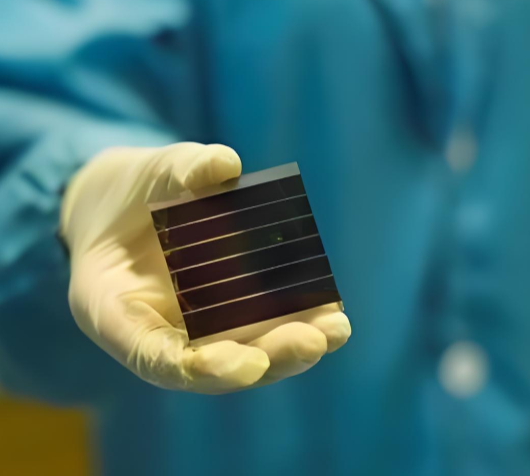

Lecheng's laser scribing technology addresses three fundamental challenges in solar panel production: electrical isolation, series interconnection, and dead zone minimization. The P1 scribe isolates the transparent conductive oxide (TCO) layer into individual strips, preventing electrical shortcuts. The P2 process creates vertical interconnections between the TCO and back electrode layers, enabling series connection of cells. Finally, the P3 scribe separates the back electrodes, completing the circuit pattern. Lecheng's systems achieve scribe widths below 30μm with positional accuracy of ±5μm, reducing dead zones to under 150μm—significantly smaller than conventional mechanical scribing methods. This precision allows more active area for light absorption on each panel, directly boosting conversion efficiency. Additionally, Lecheng's patented focus-following technology maintains consistent scribe quality across the entire panel surface, even accounting for glass thickness variations or slight warping. This consistency is vital for rooftop panels exposed to diverse weather conditions, ensuring long-term reliability and power output stability.

3. Real-World Impact: How Lecheng's Technology Enables Widespread Rooftop Solar Adoption

The practical benefits of Lecheng's laser scribing technology extend beyond manufacturing precision to tangible advantages for end-users. Homeowners and businesses benefit from higher efficiency panels that generate more electricity per square meter, making rooftop solar installations economically viable even in areas with moderate sunlight. Lecheng's large-format processing capability reduces production costs by enabling manufacturers to produce full-size panels in a single pass, rather than assembling smaller modules. This scalability has been demonstrated in multiple 100MW production lines where Lecheng's equipment maintains stable operation with over 95% uptime. The technology also supports bifacial panel production—where lasers create patterns that allow light absorption from both sides—increasing energy yield by up to 30% compared to conventional single-sided panels. As urban areas face space constraints, the ability to maximize energy generation from available rooftop space becomes increasingly valuable, positioning Lecheng's technology as a key enabler of the global transition to renewable energy.

Conclusion

Lecheng Intelligent's laser scribing technology represents more than just a manufacturing process—it's the foundation of efficient, reliable, and affordable rooftop solar energy. By transforming ordinary glass into high-performance solar panels with unprecedented precision, Lecheng is helping to power the transition to sustainable energy, one rooftop at a time.