Lecheng's Export Strategy for Laser Equipment

Localized Technical Support and Multilingual Service Networks

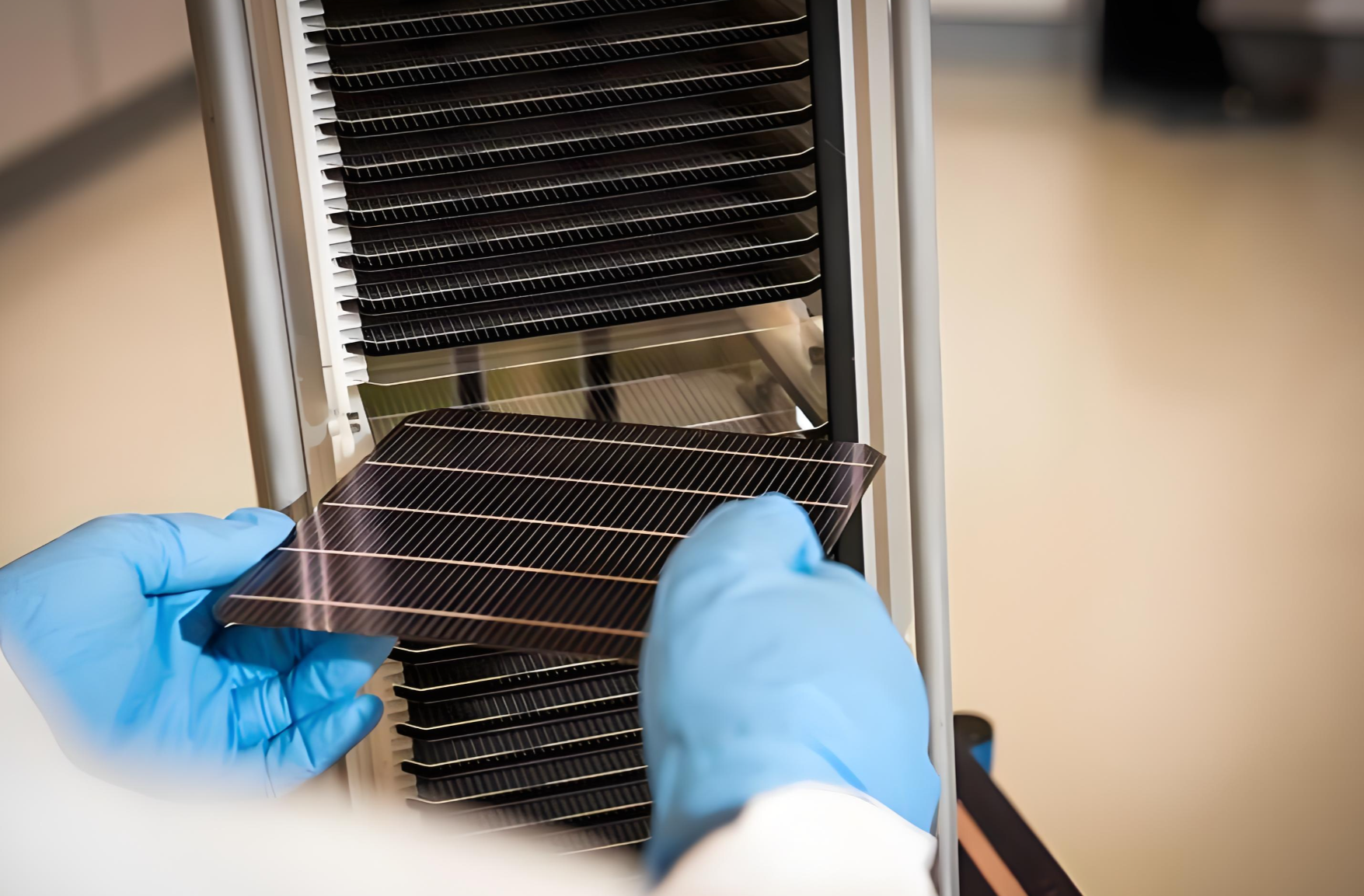

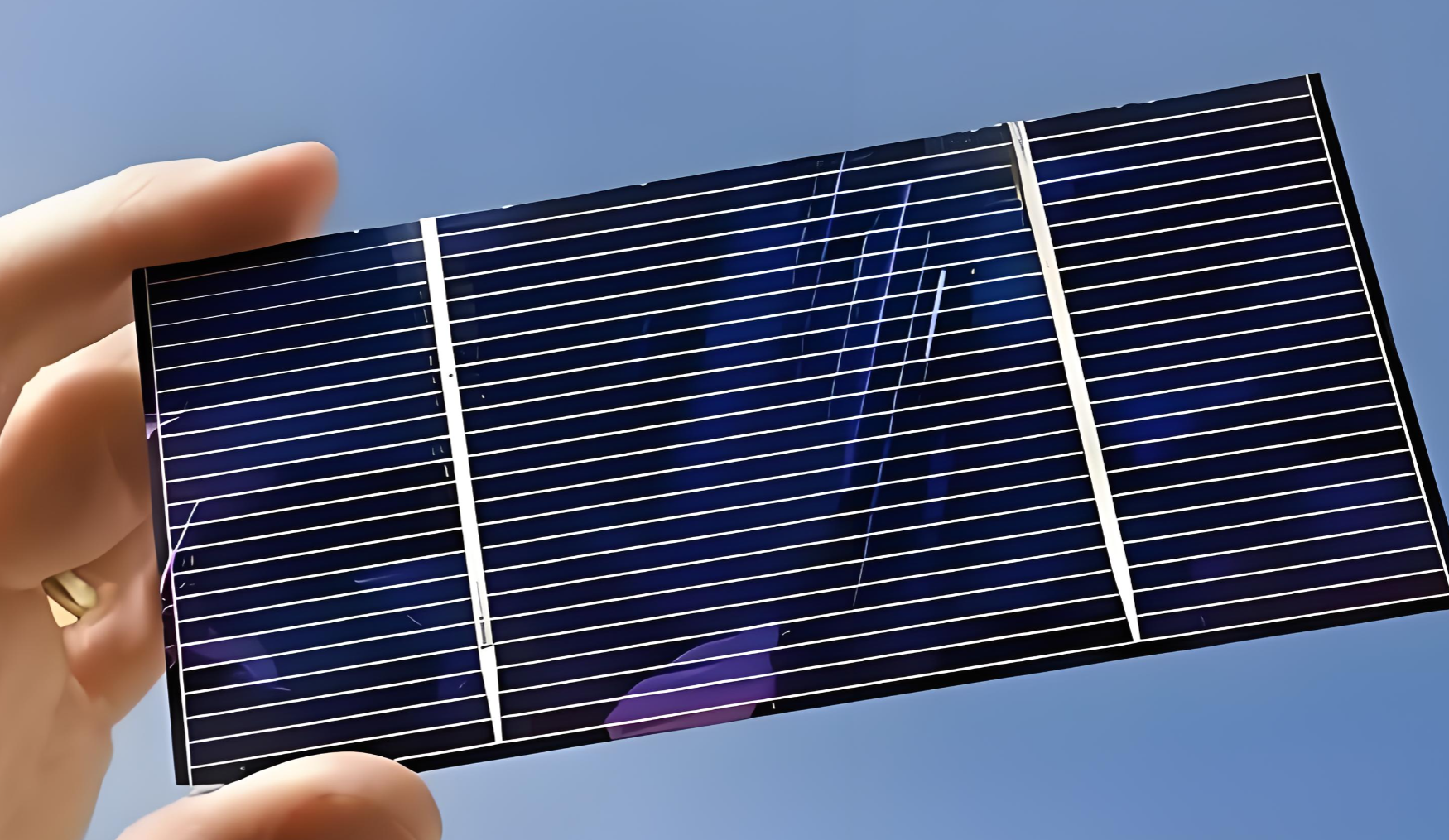

Lecheng's export strategy prioritizes localized support to overcome geographical and linguistic barriers in international markets. The company has established technical service centers in key regions (e.g., Europe, Southeast Asia, and South America), staffed with multilingual engineers fluent in English, Spanish, Russian, and Arabic. These teams provide on-site installation, debugging, and maintenance—critical for perovskite solar manufacturers requiring real-time process adjustments. For example, Lecheng's German-based service hub supports European clients with ≤48-hour response times, while its Southeast Asian center caters to flexible electronics producers in Thailand and Vietnam. By aligning operational hours with local time zones and offering training in local languages, Lecheng ensures seamless integration of its laser scribing, cutting, and welding equipment into global production lines.

Compliance with International Standards and Customization for Regional Needs

To penetrate regulated markets like the EU and North America, Lecheng certifies its equipment with CE, UL, and ISO 9001 standards—demonstrating compliance with safety, quality, and environmental protocols. The company also adapts products to regional requirements: systems destined for European solar manufacturers emphasize energy efficiency (e.g., fiber lasers with >30% wall-plug efficiency), while those for Southeast Asia focus on humidity resistance and stability in tropical climates. For R2R laser processing equipment, Lecheng offers voltage customization (110V/220V) and software interfaces in local languages. This flexibility extends to partnering with local distributors for logistics and warehousing, reducing lead times by 50% and enhancing cost-effectiveness for clients in over 18 countries.

Strategic Partnerships and Market-Driven Product Development

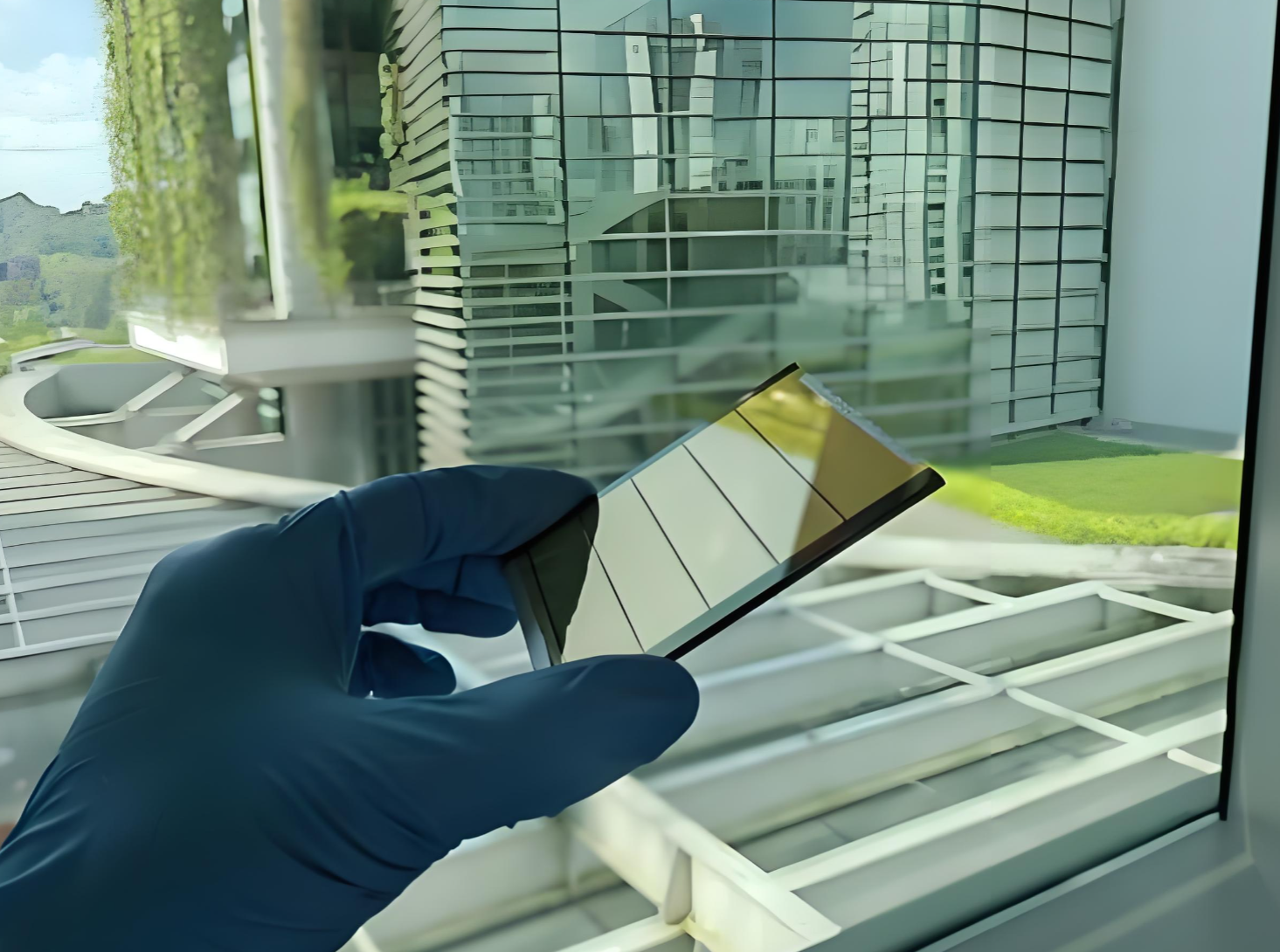

Lecheng leverages partnerships with global perovskite research institutes and solar industry associations to identify emerging needs—such as tandem cell patterning or R2R processing for flexible electronics. By collaborating with entities like the Calcium Titanium Industry Branch of China International Science and Technology Promotion Association, the company gains insights into regional technological trends, which inform R&D priorities. For instance, demand for large-area (2.4m × 1.2m) laser scribing in Europe prompted Lecheng to develop high-precision multi-beam systems, while North America’s focus on aerospace drove innovations in titanium laser cutting. These partnerships also facilitate joint marketing, with Lecheng participating in international exhibitions (e.g., Intersolar and SEMICON) to showcase solutions tailored to local industries.

Lecheng's export success stems from a triad of localized support, compliance agility, and collaborative innovation. By treating global diversity as an asset rather than a barrier, the company not only expands its market reach but also drives technological advancements that resonate across borders.