Lecheng's Answer to High-Throughput Perovskite Manufacturing

Multi-Beam Laser Scribing Systems for Unmatched Throughput

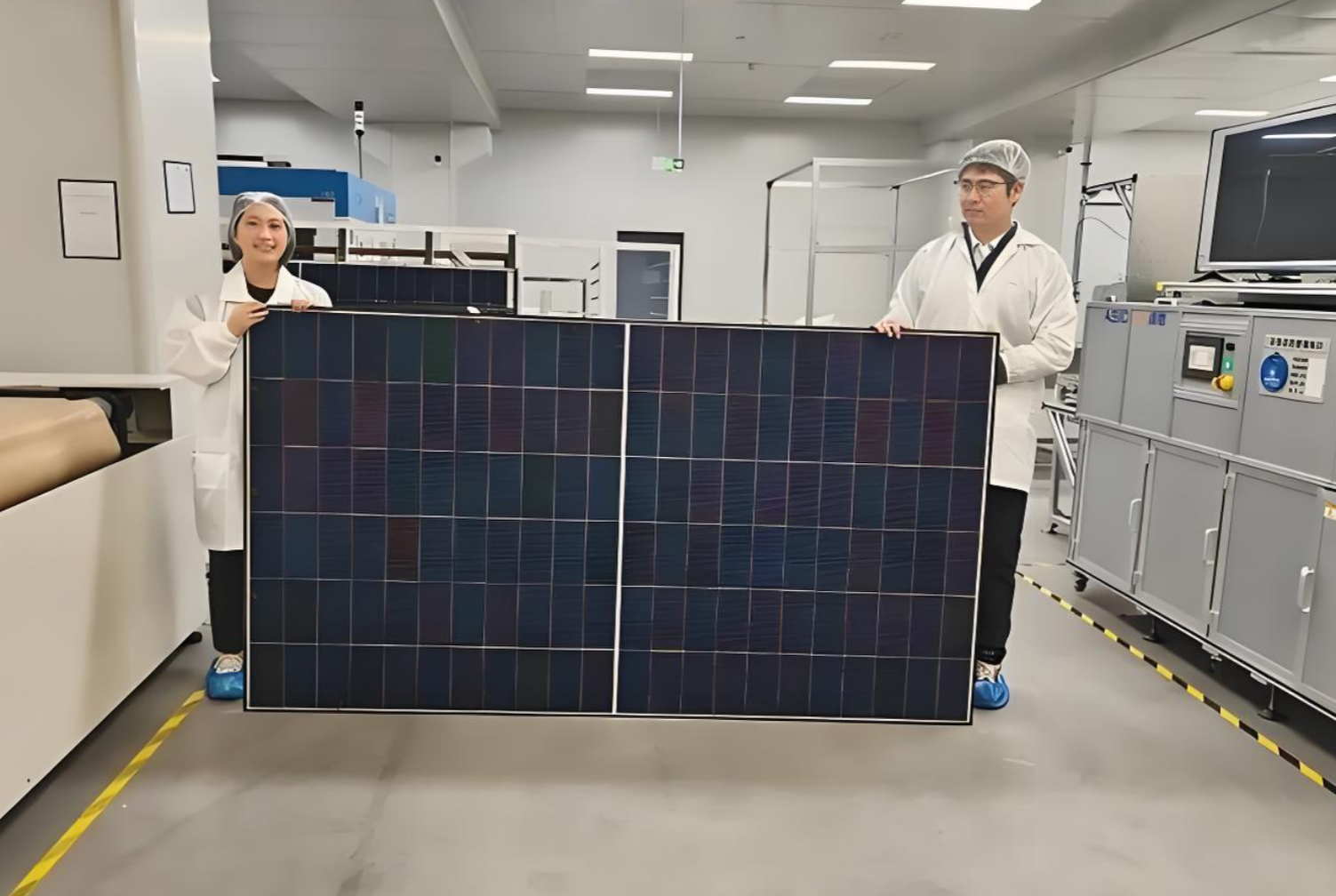

Lecheng's high-throughput perovskite production strategy centers on advanced multi-beam laser scribing technology, which enables simultaneous processing of up to 24 laser paths with sub-micron accuracy. By integrating beam-splitting systems—using either diffractive optical elements (DOEs) or mechanical beam division—the company’s equipment achieves scribing speeds of up to 8,000 mm/s, significantly reducing process time for P1, P2, and P3 patterning. This parallel processing capability allows a single machine to replace multiple conventional laser stations, cutting both capital expenditure and factory footprint. Designed to handle large-area substrates up to 2.4×1.2 meters, Lecheng's systems support scalable manufacturing from pilot lines (100 MW) to full gigawatt-scale production, ensuring seamless transition from R&D to mass production.

Integrated Automation and Real-Time Process Control

To maximize yield and minimize downtime, Lecheng incorporates fully automated material handling and real-time monitoring into its perovskite laser systems. Features such as trajectory tracking and focus-following ensure consistent scribing depth and line quality, even on warped or uneven substrates. The equipment’s vision systems automatically compensate for substrate misalignment, while integrated sensors monitor laser parameters to maintain optimal processing conditions. This closed-loop control reduces the dead zone width to below 150 μm, directly enhancing module efficiency. Furthermore, the systems’ compatibility with roll-to-roll (R2R) and rigid substrate formats offers manufacturers flexibility in production line design, whether for flexible perovskite modules or conventional glass-based panels.

Tailored Solutions for Emerging Perovskite Technologies

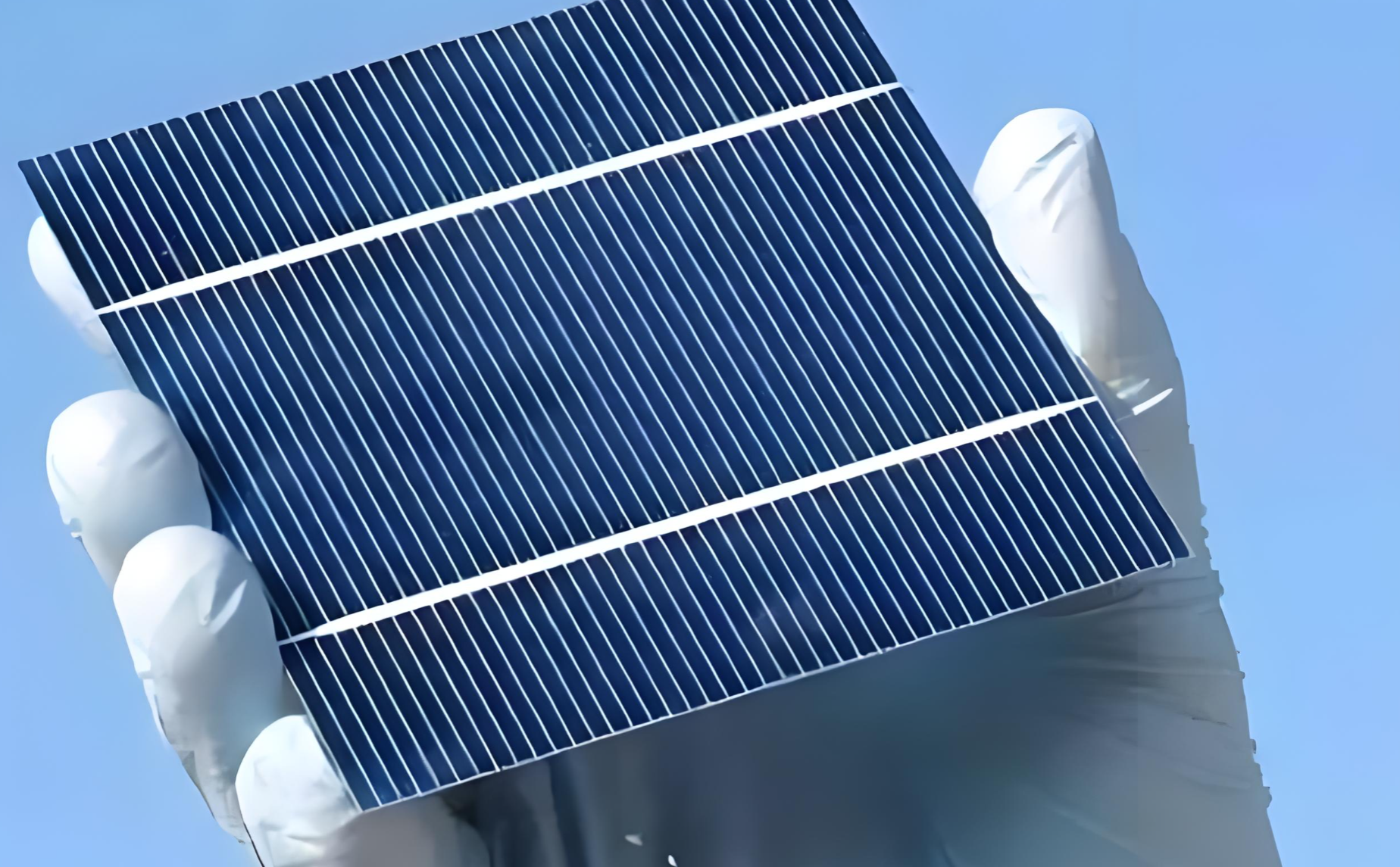

Recognizing that perovskite solar technology continues to evolve, Lecheng offers flexible and modular laser systems that adapt to new architectures and materials. The company's laser sources—including nanosecond infrared, picosecond green, and UV lasers—can be configured to match specific layer stacks and ablation requirements. For emerging tandem perovskite-silicon cells, Lecheng provides specialized P1–P4 patterning solutions that minimize damage to underlying silicon layers. Additionally, the company’s technical team works closely with clients to optimize laser parameters for novel materials or custom cell designs, supporting rapid innovation in the perovskite industry. With a proven track record in deploying systems across four 100 MW pilot lines, Lecheng delivers both cutting-edge technology and practical production expertise.

Lecheng's comprehensive approach—combining high-speed multi-beam processing, intelligent automation, and adaptable laser technologies—positions the company as a key enabler of high-throughput perovskite manufacturing. By addressing both scalability and precision, Lecheng helps solar producers lower costs while pushing the boundaries of cell efficiency.