Laser technology, characterized by its non-contact processing, high precision, and exceptional flexibility, is rapidly replacing traditional mechanical methods across industries. From ultra-fast lasers to novel applications in composite materials and electric vehicles, advancements are driving efficiency and enabling breakthroughs in fields like medical devices and renewable energy.

1. Advancements in Laser Sources

Ultrafast lasers, such as picosecond and femtosecond lasers, have achieved nanoscale processing precision, revolutionizing semiconductor and New energy battery manufacturing by significantly improving production yields. Recent innovations include on-chip picosecond mid-infrared laser pulse generators, which integrate resonators, laser sources, and filters on a single chip. These devices enable high-sensitivity gas sensing for environmental monitoring and medical imaging without external components

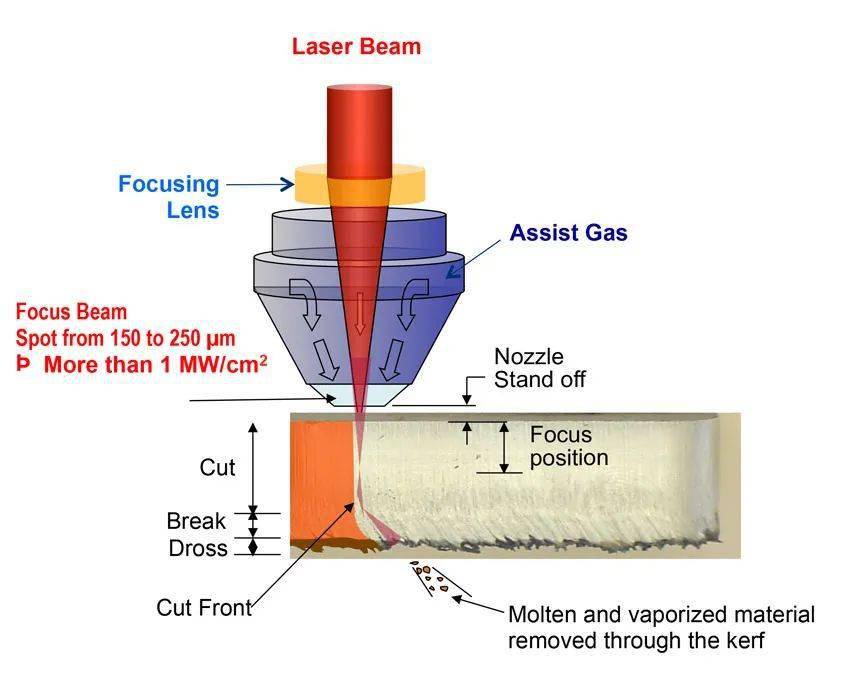

2. Processing New Materials

Laser technology is increasingly applied to composites and brittle materials. For instance, laser transmission welding reliably joins fiber-reinforced thermoplastics without mechanical stress, while laser surface treatment prepares composites for bonding and repair. Precision cutting and drilling of CFRP (carbon fiber-reinforced polymers) and GFRP (glass fiber-reinforced polymers) are now achievable with minimal damage.Blue laser technology (400–500 nm) also addresses challenges in processing high-reflectivity metals like copper and gold, offering spatter-free, pore-free welding critical for aerospace and electric vehicle battery manufacturing.

3. Expanding Applications in New Energy and Medical Devices

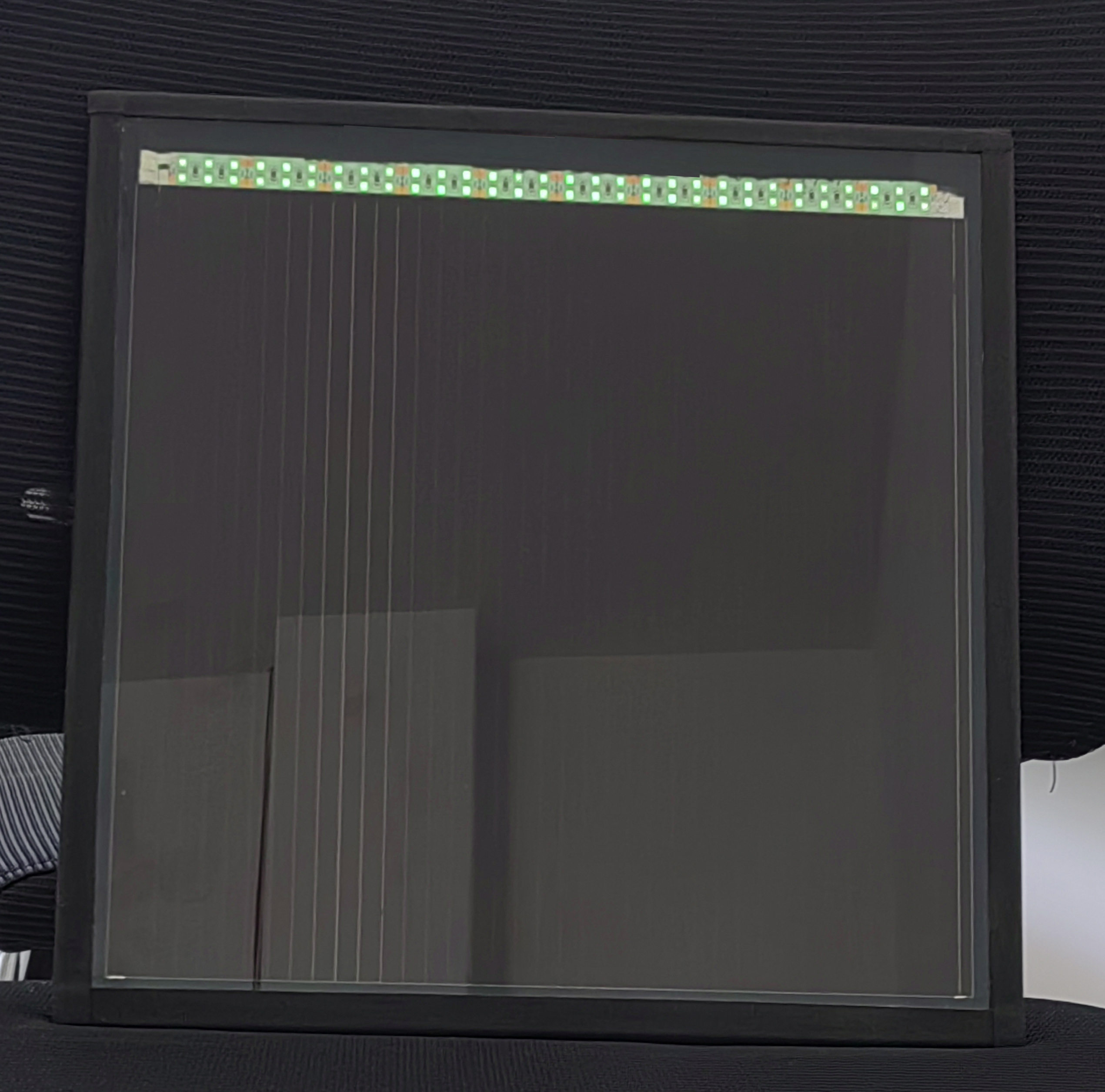

In new energy vehicles, lasers are essential for battery welding (e.g., cell caps, tabs, and modules) and lightweight body manufacturing. Laser welding of aluminum and steel composites enhances structural strength while reducing weight. Solar and hydrogen energy sectors benefit from laser processing in photovoltaic panel manufacturing and fuel cell component fabrication.

In medical devices, ultrafast lasers enable minimally invasive surgeries, precision cutting of stents, and personalized aesthetic treatments. Laser-based optical frequency combs facilitate high-resolution imaging and diagnostics, while miniaturized perovskite lasers could soon integrate into lab-on-chip devices for real-time health monitoring.4. Future Trends and Challenges

The future of laser technology emphasizes higher power, shorter pulses, and smarter integration. Trends include:

•Solar-powered laser systems for off-grid applications.

•AI-driven adaptive control for real-time process optimization.

•Miniaturization of laser sources for portable medical and electronic devices.

Challenges remain in standardizing processes for new materials and reducing costs for high-power systems. However, with ongoing research in semiconductor laser chips and quantum cascade technologies, laser applications will continue to expand into emerging fields like quantum computing and advanced sensing.

Conclusion

Laser technology’s evolution from a specialized tool to a cross-industry solution underscores its transformative impact. As innovations in sources, materials, and applications accelerate, lasers will remain at the forefront of precision manufacturing, medical advancements, and sustainable energy solutions.