Founder Spotlight

Academic Excellence as the Foundation for Innovation

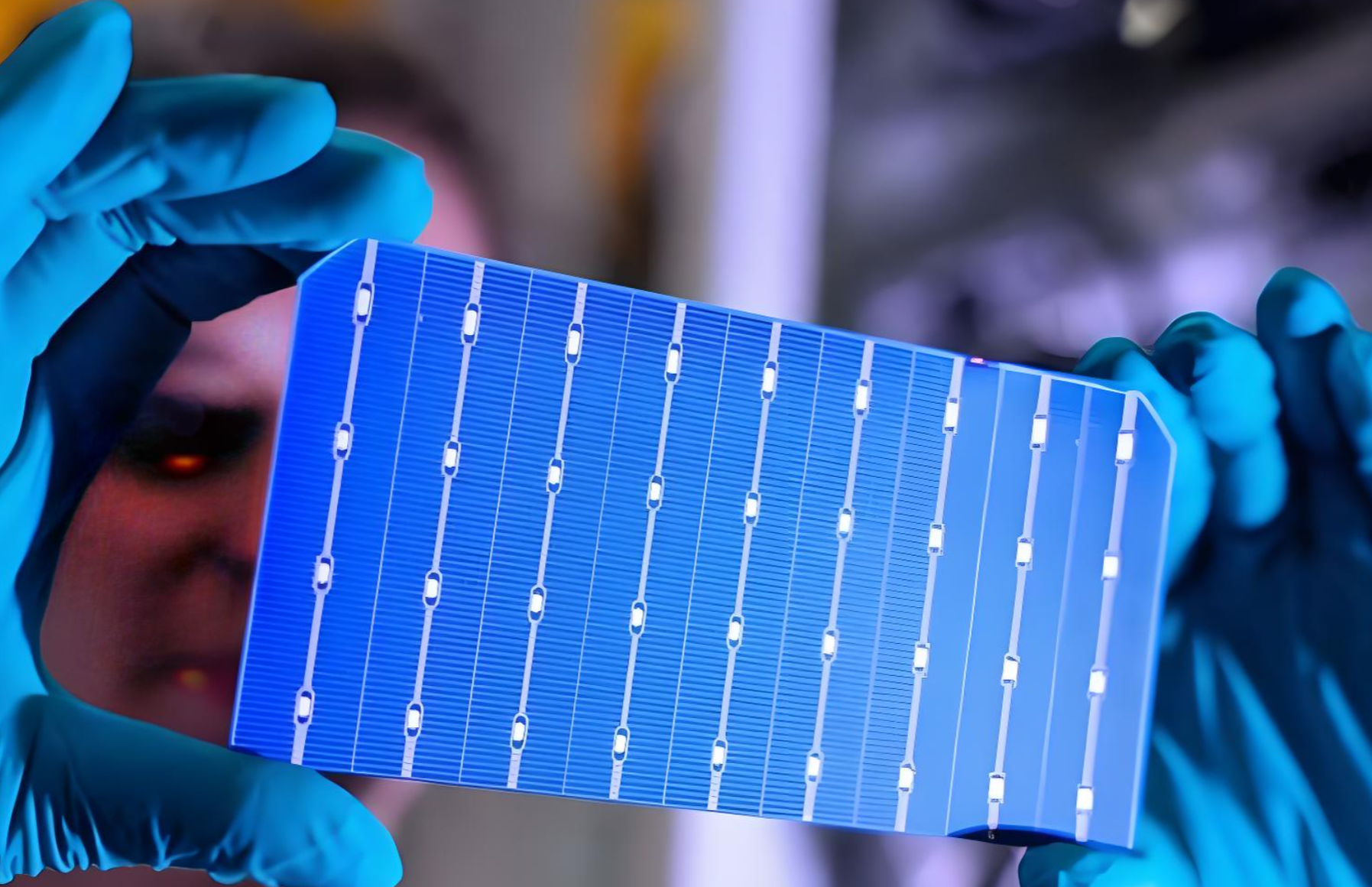

He Le's journey began with a solid academic foundation—a Bachelor's degree in Physics from Tsinghua University, followed by a Master's in Optical Engineering from Shanghai Jiao Tong University. This rigorous training in fundamental sciences and engineering principles equipped him with the technical depth to identify gaps in laser precision machining. At Tsinghua, he developed a keen interest in photonics and material interactions, which later fueled his focus on laser applications for renewable energy and advanced electronics. His academic research involved early explorations of laser ablation mechanisms, laying the groundwork for Lecheng's future breakthroughs in thin-film solar patterning and ultra-fine processing. This blend of theoretical knowledge and practical curiosity became the bedrock of Lecheng's R&D philosophy: solving industrial challenges with scientific rigor.

Bridging R&D and Commercialization

Before founding Lecheng, He Le served as an R&D project manager at a listed laser company, where he led projects on FPC laser drilling and PERC solar cell scribing. This experience exposed him to the pain points of high-precision manufacturing: the need for faster throughput, better yield, and adaptable automation. He recognized that many laser systems lacked the flexibility to handle evolving materials like perovskite layers or the scalability for gigawatt production. At Lecheng, he channeled these insights into developing modular, multi-functional platforms—such as the R2R laser scribing systems that now support 12-beam processing and real-time trajectory tracking. His hands-on approach extends to directly managing the R&D and production teams, ensuring that client feedback is rapidly integrated into product iterations.

Building a Globally Competitive Enterprise

As Chairman and General Manager, He Le has steered Lecheng from a startup to a trusted partner for perovskite and thin-film solar leaders. Under his leadership, the company has secured Series A funding, established a 2,500㎡ production base in Changshu Economic Development Zone, and deployed equipment in over 18 countries. His vision extends beyond hardware: he advocates for “technology as a service,” offering clients end-to-end support from process debugging to after-sales maintenance. By fostering partnerships with top perovskite manufacturers and research institutes, he ensures Lecheng remains at the forefront of laser innovations—such as integrating AI for predictive maintenance or advancing beam-splitting technologies for higher throughput. His ultimate goal is to make Lecheng a synonym for reliability and innovation in the global laser equipment market.

He Le's trajectory—from Tsinghua's labs to the helm of a laser technology pioneer—embodies the fusion of scholarly depth and entrepreneurial action. By aligning cutting-edge research with industrial needs, he has positioned Lecheng as a catalyst for advancements in green energy and smart manufacturing.