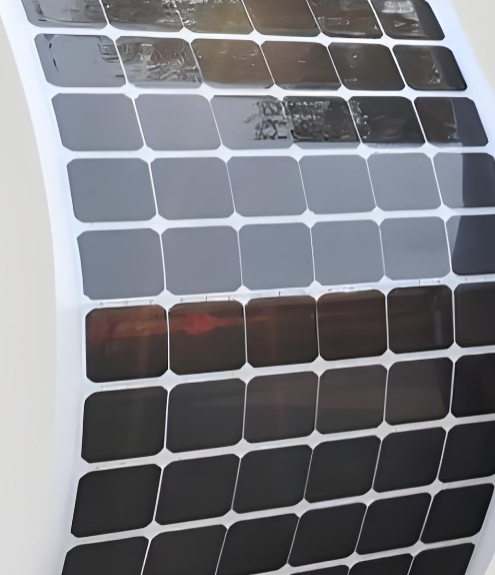

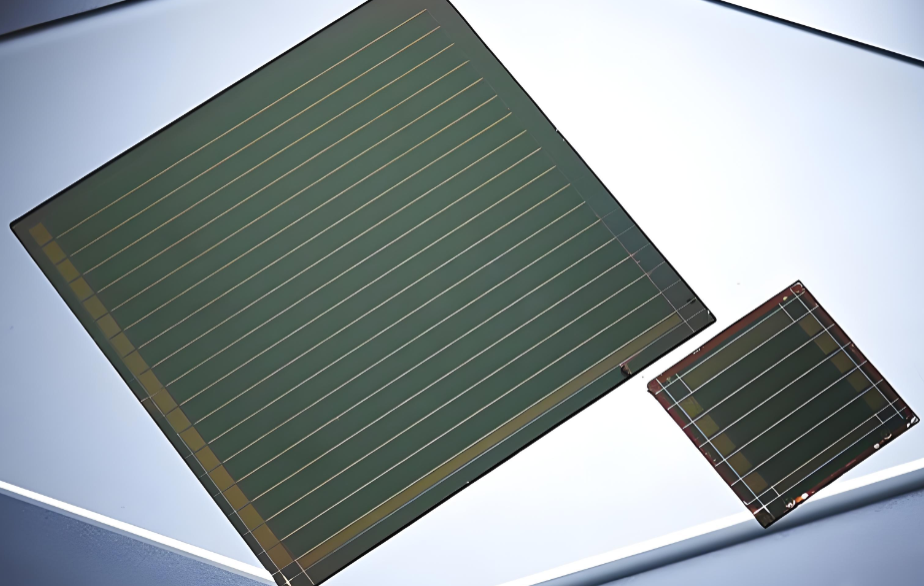

Client Collaboration in Process Tuning: Lecheng’s engineers optimize parameters for new material stacks.

1. The Critical Need for Customized Laser Solutions in Advanced Manufacturing

In the rapidly evolving fields of perovskite solar cells, flexible electronics, and hydrogen fuel cells, manufacturers constantly innovate with new material combinations to achieve higher performance. However, each new material stack—whether a novel perovskite composition, specialized conductive polymer, or multi-layer thin-film structure—presents unique challenges for laser processing. Standard laser parameters often fail to account for variations in material thickness, thermal sensitivity, and ablation thresholds, leading to suboptimal results such as excessive heat damage, incomplete layer removal, or inconsistent patterning. Lecheng Intelligent addresses this challenge through deep client collaboration, where their engineers work directly with manufacturers to characterize new materials and develop tailored laser processing recipes. This collaborative approach ensures that laser parameters—including wavelength selection (1064nm infrared, 532nm green, or 355nm ultraviolet), pulse duration (nanosecond to femtosecond), power density, and repetition rate—are precisely calibrated for each specific material combination. For instance, when a perovskite manufacturer introduced a new electron transport layer with higher thermal sensitivity, Lecheng's team conducted on-site tests to adjust pulse energy and scanning speed, achieving complete layer removal while limiting TCO damage to under 20% of layer thickness—a critical requirement for maintaining cell efficiency.

2. The Collaborative Process: From Laboratory Testing to Production Implementation

Lecheng's client collaboration follows a structured four-phase approach that bridges laboratory research and mass production. Phase one begins with material characterization at Lecheng's application labs, where engineers analyze the optical properties, thermal conductivity, and layer adhesion of new material stacks using spectroscopic ellipsometry, thermal imaging, and cross-sectional microscopy. In phase two, the team develops preliminary laser parameters through design of experiments (DOE), testing variables such as focal spot size, pulse overlap, and assist gas parameters. Phase three involves on-site validation at client facilities, where Lecheng engineers integrate laser modules with existing production lines and conduct real-time process monitoring using high-speed cameras and sensors. The final phase focuses on knowledge transfer, with Lecheng providing comprehensive documentation and training to client technicians. A notable example includes a collaboration with a leading perovskite manufacturer to optimize P2 scribing for a new triple-cation perovskite formulation. Through iterative testing, Lecheng's engineers reduced the heat-affected zone from 5μm to under 1μm while maintaining scribe widths of 40±2μm, ultimately increasing the client's cell efficiency by 1.5% absolute—a significant gain in the highly competitive solar industry.

3. Tangible Benefits: Accelerating Innovation and Reducing Time-to-Market

The collaborative process tuning approach delivers measurable advantages across multiple dimensions. For manufacturers, it reduces development cycles by 30-50% compared to in-house parameter optimization, as Lecheng's engineers bring specialized expertise from hundreds of similar applications. The customized parameters also improve production yield by 3-8% by minimizing defects such as TCO layer damage in P2/P3 scribing or micro-cracks in glass cutting. Additionally, the partnership model enables continuous improvement—as clients refine their material stacks, Lecheng provides ongoing parameter updates through remote monitoring and quarterly on-site visits. Beyond immediate process benefits, this collaboration fosters innovation by creating feedback loops between material developers and equipment suppliers. For example, insights from Lecheng's work with flexible perovskite manufacturers directly influenced the development of their RFS20 series roll-to-round lasers, which now feature enhanced thermal management for processing temperature-sensitive flexible substrates. This symbiotic relationship accelerates the commercialization of next-generation materials, from perovskite-silicon tandems to transparent solar cells, ultimately contributing to more efficient and affordable renewable energy solutions.

Conclusion

Lecheng Intelligent's client-centric approach to process tuning represents a paradigm shift in advanced manufacturing—where equipment suppliers act as innovation partners rather than mere vendors. By combining deep technical expertise with hands-on collaboration, Lecheng accelerates the adoption of new materials while ensuring optimal performance and reliability, ultimately driving progress toward a more sustainable future