Laser Marking on Metals, Plastics, and Ceramics

High-Contrast Permanent Marking on Metallic Surfaces

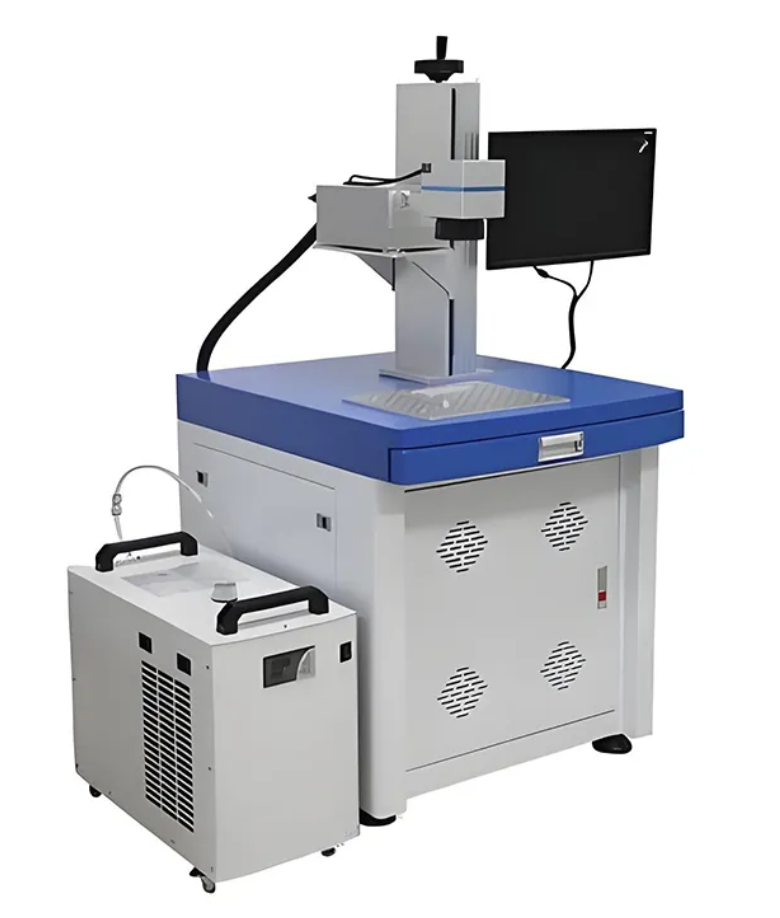

Lecheng's fiber laser marking systems achieve exceptional results on various metals including stainless steel, aluminum, titanium, and copper alloys. Using precise wavelength control (1064nm) and adjustable pulse durations, these systems create permanent marks with contrast ratios exceeding 80% without compromising material integrity. The non-contact process eliminates tool wear while maintaining marking speeds up to 7000mm/s with positional accuracy of ±0.01mm. For medical implants and aerospace components, Lecheng's lasers produce USP-compliant Unique Device Identification (UDI) codes that withstand autoclave sterilization and extreme environmental conditions. The integrated vision system automatically verifies mark quality against ISO 9001 standards, ensuring 100% traceability for high-value industrial applications.

Precision Engraving on Engineering Plastics and Polymers

For plastic materials ranging from ABS and polycarbonate to PEEK and PTFE, Lecheng's UV laser systems (355nm wavelength) enable clean, high-resolution markings without thermal damage. The cold ablation process prevents melting or deformation, achieving feature sizes as small as 0.1mm with exceptional edge definition. This technology is particularly valuable for electronic components, where Lecheng's systems mark QR codes, serial numbers, and logos on circuit boards and connector housings with 600 DPI resolution. The environmentally friendly process requires no inks or chemicals, making it ideal for medical devices and consumer electronics that demand biocompatibility and sustainability. Automatic material detection sensors adjust laser parameters in real-time, ensuring consistent quality across different polymer compositions.

Ceramic and Glass Marking with Micro-Cracking Control

Lecheng's laser solutions address the unique challenges of ceramic materials, including alumina substrates, zirconia implants, and glass components. Using optimized pulse shaping technology, the systems create crisp, durable marks while controlling micro-cracking to below 5μm depth. For multilayer ceramic capacitors (MLCCs) and electronic substrates, the laser parameters are precisely tuned to avoid delamination or structural compromise. The integrated rotary attachment enables 360-degree marking on cylindrical components, while the high-speed galvo system handles complex graphics and barcodes on flat surfaces. This versatility makes Lecheng's equipment suitable for diverse applications from automotive sensors to decorative ceramics, with marking permanence guaranteed for the product's entire lifecycle.

Lecheng's comprehensive laser marking portfolio demonstrates remarkable adaptability across material categories, combining precision engineering with intelligent automation to deliver permanent identification solutions that meet the stringent requirements of modern manufacturing.