Innovative Applications of Laser Technology in the New Energy Sector

Laser technology has become a cornerstone of innovation in the new energy industry, enabling breakthroughs in efficiency, precision, and sustainability across battery manufacturing, photovoltaics, and hydrogen energy systems. Its non-contact processing, micron-level accuracy, and flexibility make it indispensable for next-generation energy solutions. Here are key innovative applications driving this transformation:

1. Revolutionizing Battery Manufacturing

- Cylindrical Full-Tab Battery Welding

Laser welding addresses critical challenges in cylindrical full-tab battery production, such as micro-level metal foil shaping and high-precision welding. Companies like Yifei Laserhave developed automated assembly lines capable of producing 360 batteries per minute, significantly enhancing production efficiency and quality for industry leaders like CATL and BYD.

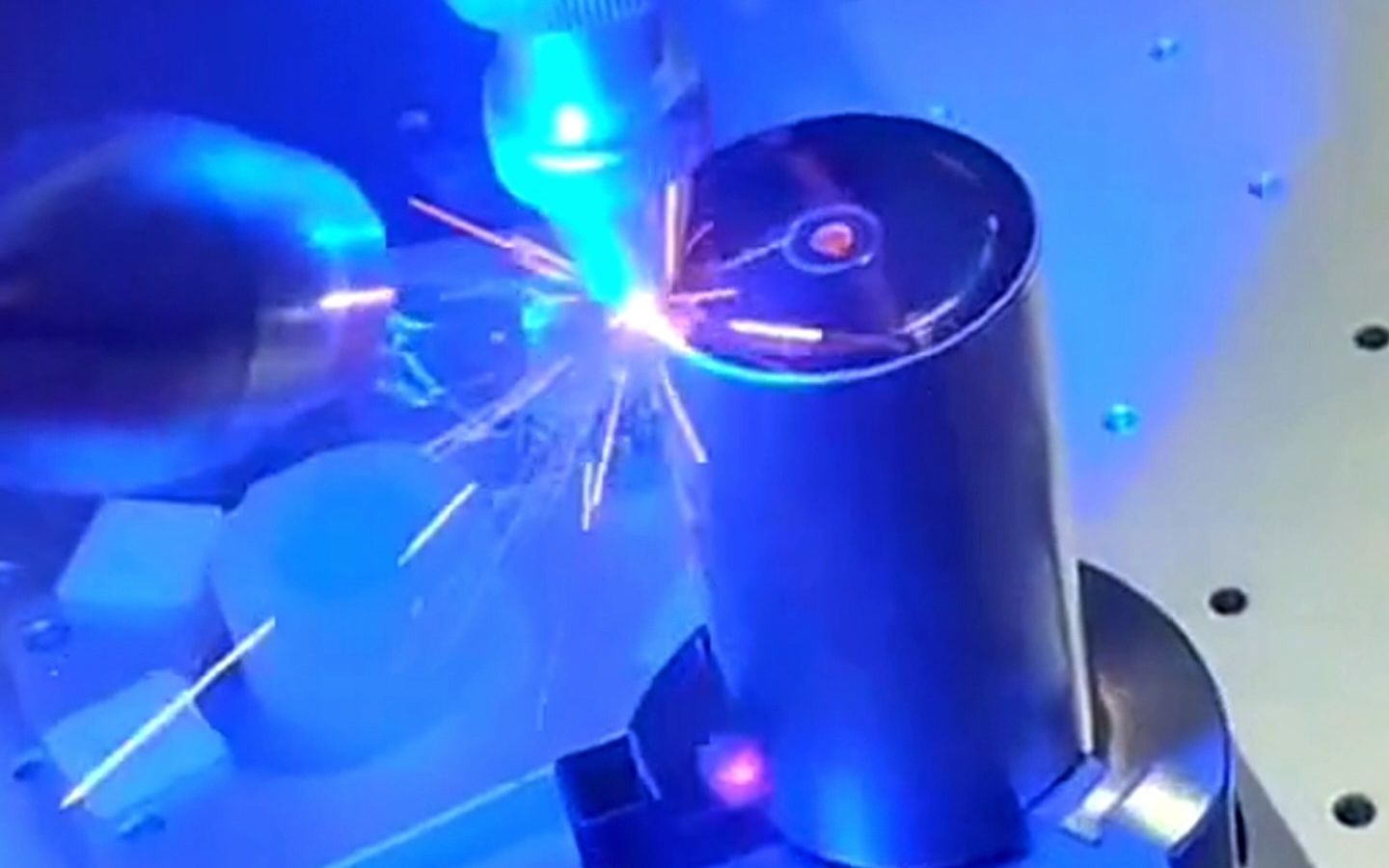

- High-Reflectivity Material Processing

Copper and aluminum, essential for battery components, highly reflect laser light, complicating welding. Innovations like blue-light infrared composite lasers(e.g., Baochenxin’s HMB 3000) increase absorption rates for copper, enabling stable, spatter-free welds with 99.9% yield in critical areas like cell cases and explosion-proof valves.

- Electrode Processing and Safety Enhancements

Lasers are used for anode electrode scoring(achieving ±1μm depth tolerance) and cell case texturing, which improves spray coating adhesion and structural strength by over 100%, enhancing battery safety

. For explosion-proof valves, laser welding ensures precise pressure control (0.4–0.7 MPa rupture threshold), critical for preventing thermal runaway.

2. Advancing Solar Photovoltaics

- Perovskite Solar Cell Processing

Ultrafast lasers enable micron-precision patterning, edge cleaning, and drilling for perovskite cells. Yifei Laser’scalcio-titanium ore battery equipment achieves 98% operational stability, supporting high-efficiency perovskite module production

. Low-cost nanosecond lasers have also been used to create modules with 21.07% efficiency, reducing manufacturing costs without compromising performance.

- PERC and TOPCon Cell Efficiency

Laser doping and ablation techniques boost cell efficiency. For example, Reis Laser’sBC cell processing technology helps TOPCon cells exceed 26% efficiency

. Laser boron doping in TOPCon cells reduces silver consumption and enhances conductivity, while laser annealing improves HJT cell passivation and reduces decay.

- Glass-Glass Encapsulation

Femtosecond lasers weld homogeneous glass structures for double-glass modules, creating hermetic seals that block moisture ingress. This eliminates the need for traditional polymer edge seals, reduces material costs, and extends module lifespan by preventing corrosion.

3. Enabling Hydrogen Energy Infrastructure

- Fuel Cell Bipolar Plate Processing

Lasers precision-machine flow channels in bipolar plates, achieving 10μm accuracy and increasing power density by 15%. This is critical for optimizing reactant distribution and efficiency in hydrogen fuel cells.

- Laser Cladding for Corrosion Resistance

Laser cladding adds wear-resistant coatings to critical components in electrolyzers and hydrogen storage systems, enhancing durability in corrosive environments.

4. Emerging Applications and Future Trends

- Grid-Scale Energy Storage Systems

Lasers weld battery modules and packs for large-scale storage, ensuring robust connections and thermal management. Yifei Laser’smodular assembly solutions cover everything from cell-to-pack integration to containerized storage systems.

- Green Hydrogen Production

Lasers are used to manufacture electrolysis cells with optimized catalysts and membranes, improving hydrogen production efficiency.

- AI and Digital Integration

Combining lasers with AI-driven quality control (e.g., real-time weld monitoring) and digital twins allows for predictive maintenance and adaptive manufacturing, reducing downtime and waste.

Conclusion

Laser technology is accelerating the new energy transition by solving key manufacturing challenges and enabling high-performance, cost-effective solutions. From battery safety and solar efficiency to hydrogen infrastructure, innovations in laser applications are critical for achieving global sustainability goals. Future advancements will focus on multi-wavelength lasers, AI integration, and scalable processes for emerging technologies like solid-state batteries and green hydrogen.