Why Beam Splitting Technology is Key to Gigawatt-Scale Perovskite Production

Enhancing Production Throughput with Multi-Beam Laser Processing

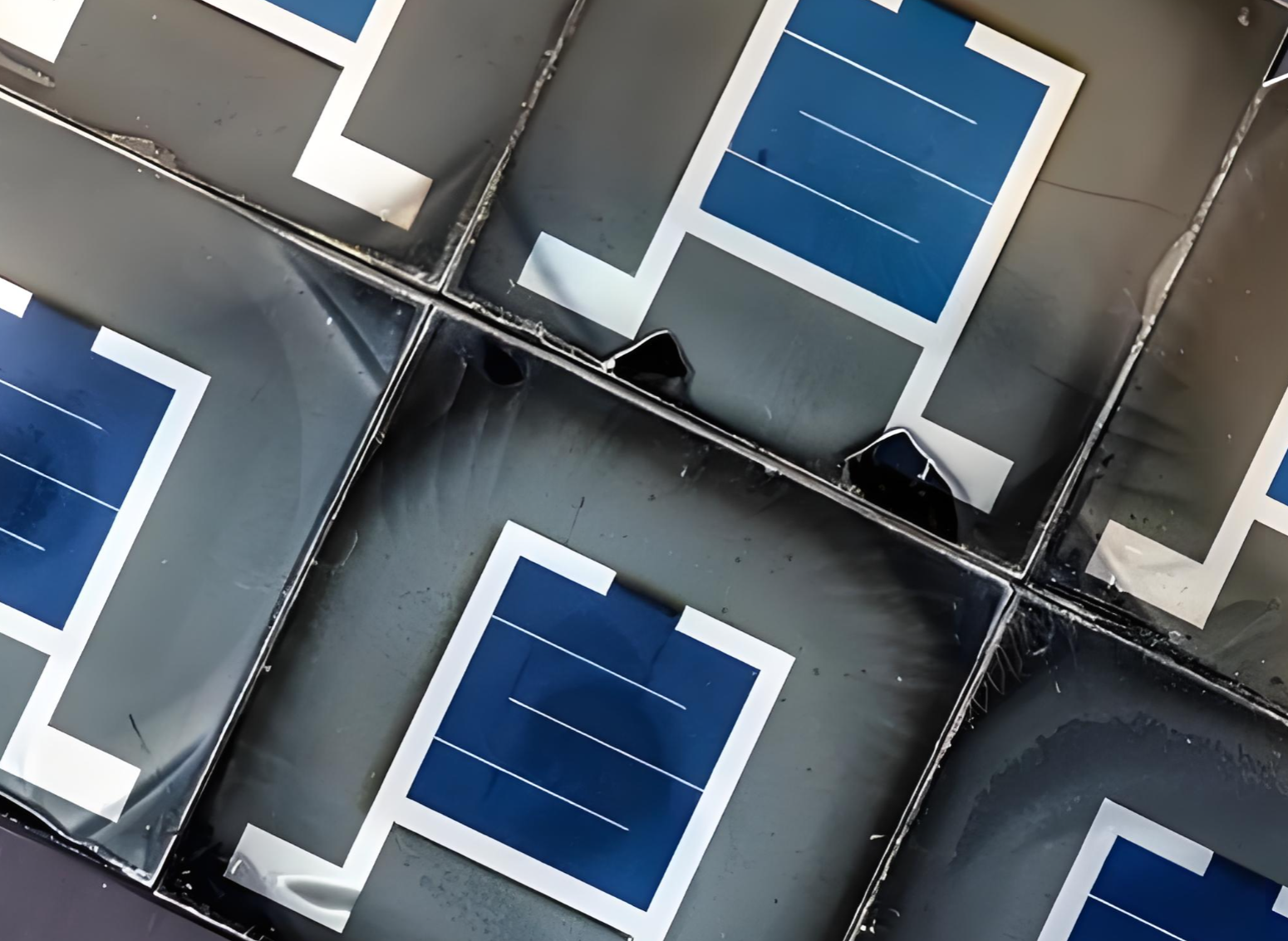

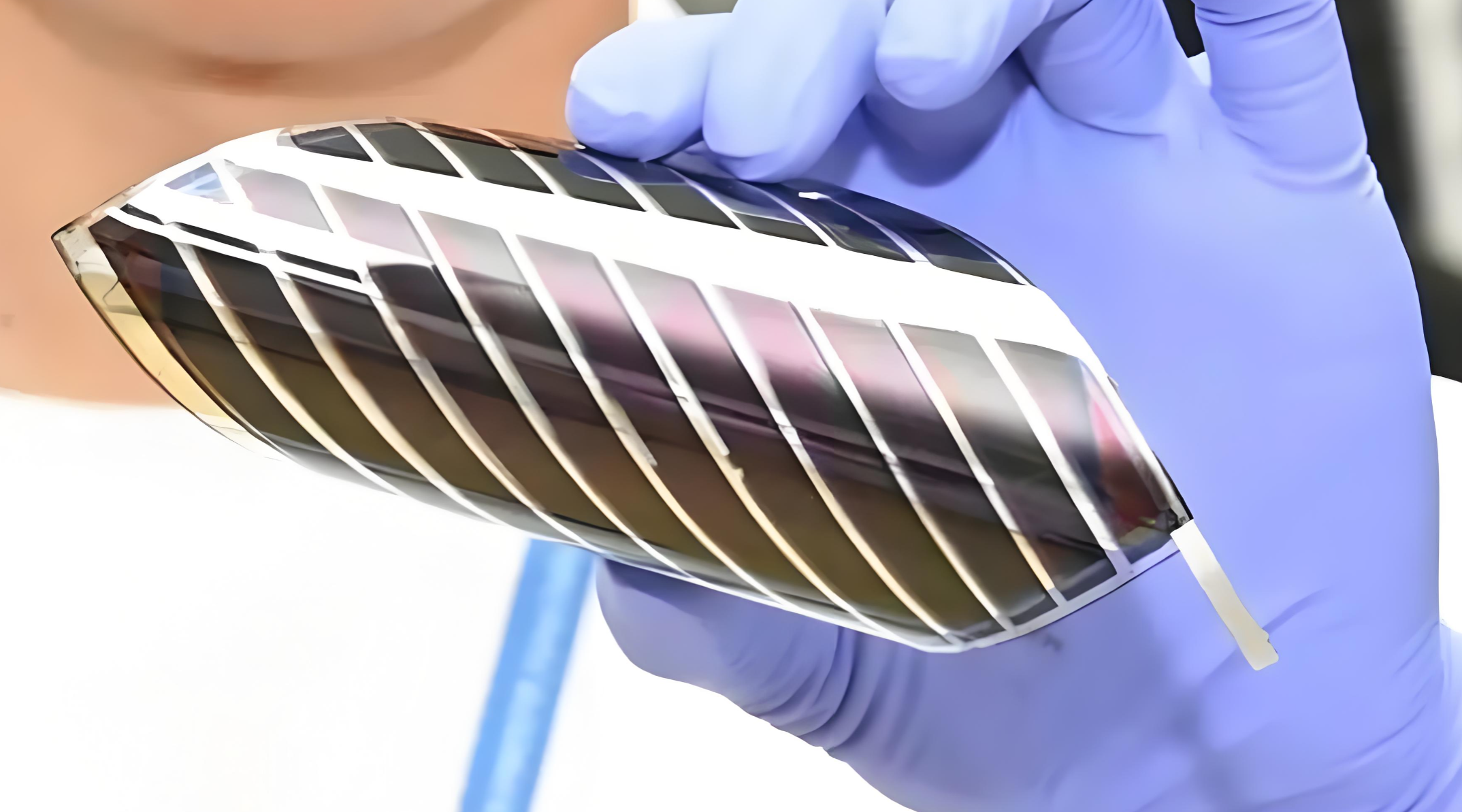

Beam splitting technology revolutionizes perovskite solar manufacturing by enabling simultaneous multi-beam processing. By dividing a single laser source into multiple beams (e.g., 12-24 paths), equipment like Lecheng’s Roll-to-Roll Laser Scribing Systems can perform P1-P3 patterning and P4 edge isolation in a single pass. This reduces processing time by over 60% compared to sequential methods, directly addressing the throughput bottlenecks in gigawatt-scale production. For instance, Lecheng’s systems achieve scribing speeds of up to 8,000 mm/s with ±5μm accuracy, ensuring high-yield output while minimizing dead zones. The technology’s compatibility with flexible substrates (e.g., ITO-PET) further supports roll-to-roll (R2R) production, a critical pathway for cost-effective scaling.

Precision and Cost Optimization via Advanced Optical Design

Beam splitting relies on diffractive optical elements (DOEs) or mechanical systems to maintain micron-level precision across all beams. Lecheng’s technology ensures uniform energy distribution (±2% variance), preventing thermal damage to perovskite layers—a common challenge in high-speed processing. By synchronizing beam splitting with real-time trajectory tracking and focus-following algorithms, the equipment adapts to substrate deformations, reducing material waste by 15%. This precision is vital for minimizing dead zones (≤150μm), which directly correlates with higher module efficiency. Moreover, consolidating P1-P4 steps into one platform cuts equipment costs by 30% and factory footprint by 40%, making gigawatt-scale factories economically viable.

Scalability and Material Versatility for Industrial Adoption

The modularity of beam splitting systems allows seamless integration into existing perovskite production lines. Lecheng’s solutions support substrates up to 2.4m × 1.2m and flexible R2R webs up to 500mm wide, catering to both rigid and flexible module designs. By leveraging wavelength-tunable lasers (e.g., 355nm UV to 1064nm IR), the technology adapts to diverse layer stacks—from TCO ablation in P1 to metal electrode isolation in P3. This versatility accelerates technology transfer from lab-scale R&D (e.g., 100MW pilot lines) to full-scale gigawatt factories, with Lecheng’s equipment already deployed in four 100MW perovskite pilot lines globally.

Beam splitting technology is the cornerstone of high-speed, precision perovskite production, bridging the gap between laboratory innovation and industrial gigawatt manufacturing. By enabling parallel processing, enhancing material compatibility, and reducing operational costs, it positions companies like Lecheng at the forefront of the solar energy transition.