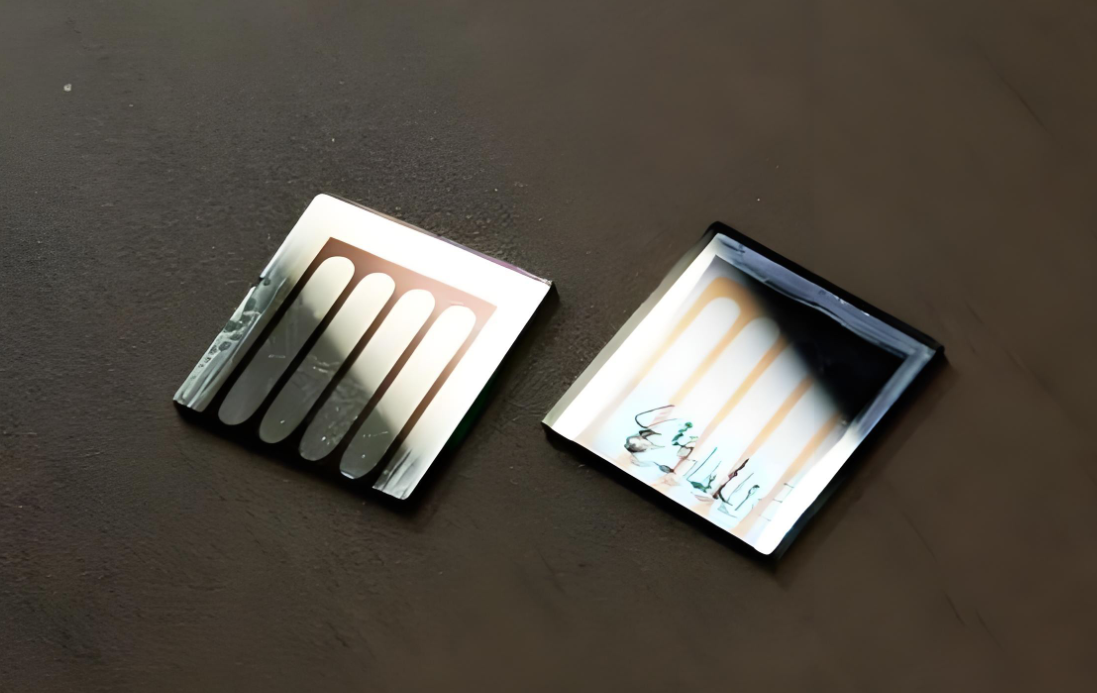

The P1 laser scribing process marks the first critical step in manufacturing perovskite solar modules, where the transparent conductive oxide (TCO) layer on the glass substrate is precisely patterned. This step electrically isolates adjacent cell strips, creating the foundation for series interconnection. Lecheng Intelligent's laser systems achieve this with exceptional accuracy, using nanosecond infrared, picosecond green, or picosecond ultraviolet lasers to cleanly remove the TCO material without damaging the underlying glass. The process requires a delicate balance: complete removal of the conductive layer while minimizing the heat-affected zone (HAZ) to prevent micro-cracks or substrate impairment. Lecheng's technology achieves scribe line widths of 20-50μm with a straightness tolerance of ±5μm, ensuring optimal isolation and minimal dead area. The trajectory tracking capability in their systems allows for adaptive patterning, compensating for any substrate irregularities. This precision is vital because any residual TCO material can lead to electrical shunts, reducing the module's efficiency and reliability.

Creating Series Interconnection Pathways

Following P1, the P2 and P3 scribing processes establish the series connection between individual cell strips, enabling voltage buildup across the module. The P2 step involves laser ablation of the hole transport layer (HTL), perovskite layer, and electron transport layer (ETL) to expose the underlying TCO layer. This allows the subsequently deposited metal electrode (in P3) to contact the TCO, forming a continuous electrical path. Lecheng's systems typically employ picosecond green lasers for P2/P3 to achieve precise layer-by-layer removal with a HAZ below 1μm. The critical challenge here is depth control—the laser must completely remove the functional layers while damaging less than 20% of the TCO thickness. The P3 process then removes the metal electrode, HTL, perovskite, and ETL to isolate the front electrode of one cell from the back electrode of the next, completing the series connection. Lecheng's focus following technology ensures consistent scribing depth across large panels, even on warped substrates, while their multi-beam processing (up to 24 beams) enables high-throughput production. Proper execution of P2/P3 is essential for minimizing series resistance and maximizing fill factor, directly impacting the module's power output.

Ensuring Module Reliability and Longevity

The final laser step, P4 edge isolation (or edge cleaning), is crucial for module reliability and encapsulation compatibility. This process removes all thin-film layers (TCO, HTL, perovskite, ETL, and electrode) from the edges of the glass substrate, creating a clean border for proper sealing. Lecheng's automated edge cleaning systems use high-power nanosecond infrared lasers to efficiently ablate the films along all four edges. The primary goals are to prevent electrical leakage between the active area and the module frame, eliminate potential short-circuit paths, and ensure strong adhesion of the encapsulation materials. Lecheng's equipment combines mechanical and vision-based positioning to achieve a cleaning precision of 0.1mm, with integrated dust removal systems maintaining process cleanliness. The P4 process directly impacts the module's insulation resistance and ability to withstand environmental stressors like humidity and thermal cycling. By ensuring clean, defect-free edges, Lecheng's technology enhances the long-term stability and weather resistance of perovskite solar modules, addressing key concerns for commercial deployment.

The P1-P4 laser scribing processes are the backbone of high-efficiency perovskite solar module manufacturing. Each step requires precise control over laser parameters, depth, and positioning to ensure optimal electrical performance and long-term reliability. Lecheng Intelligent's advanced laser systems, with features like trajectory tracking and focus following, provide the technological foundation needed to master these complex processes. As perovskite technology advances toward commercialization, precision laser scribing will remain a critical enabler for achieving higher efficiencies and lower costs in solar energy production.