One Machine for Multiple Perovskite Processes

Integrated Laser Processing: Revolutionizing Perovskite Solar Cell Manufacturing

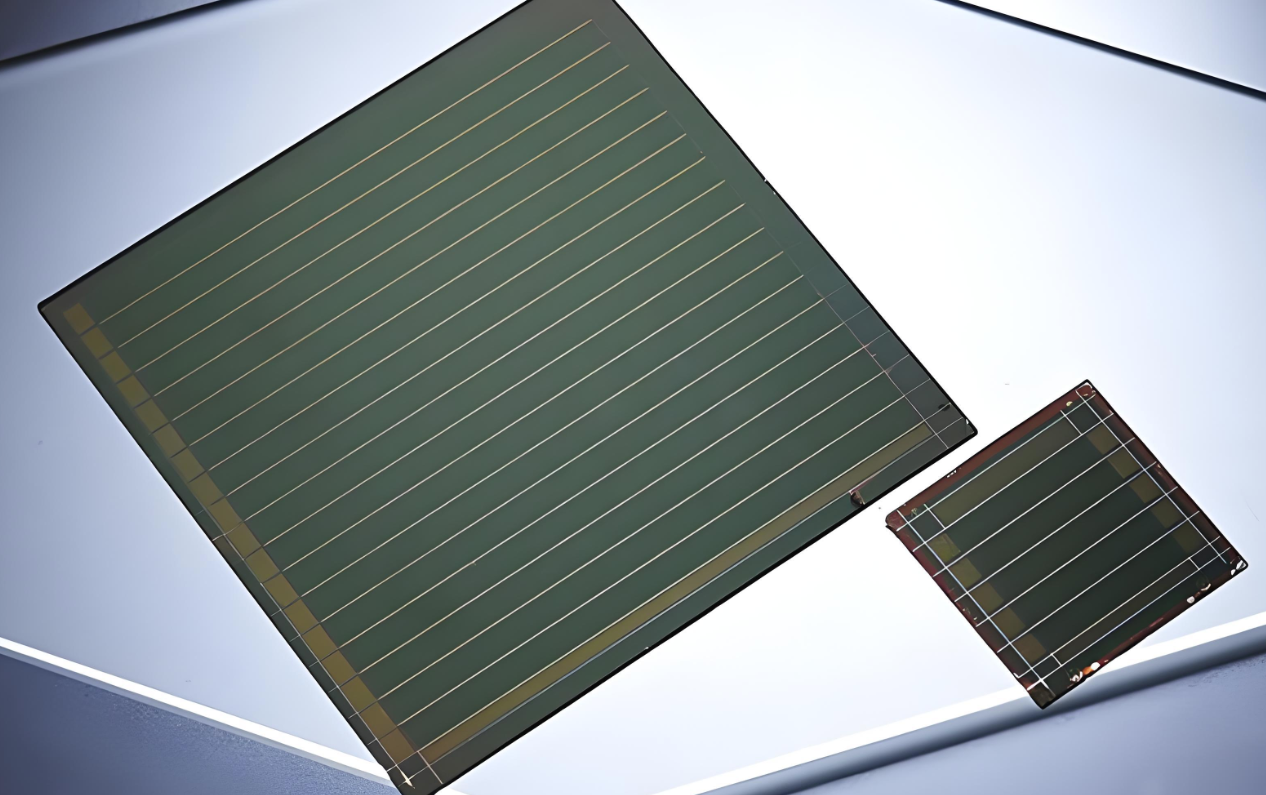

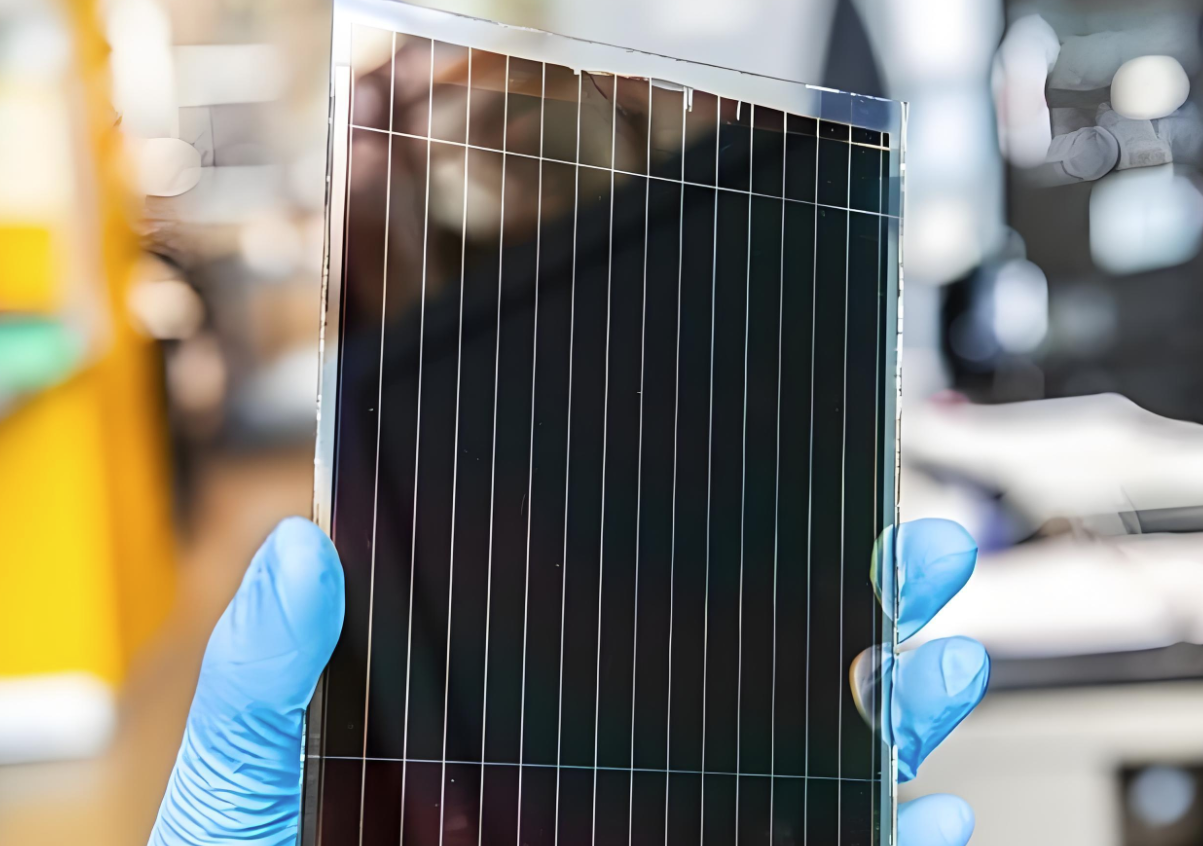

The manufacturing of perovskite solar cells involves multiple precise laser processes—P1, P2, P3 scribing, and P4 edge isolation—each traditionally requiring dedicated equipment. Lecheng Intelligent’s innovative approach consolidates these steps into a single, multi-functional laser system, significantly enhancing production efficiency and reducing operational complexity. By integrating dual or triple laser sources (e.g., nanosecond infrared, picosecond green, and ultraviolet lasers) into one platform, the machine can sequentially or selectively perform all critical scribing and cleaning tasks. This unified design eliminates the need for transferring substrates between machines, minimizing handling damage and contamination risks. For example, the FCS-10 series supports large-format panels up to 2,400mm × 1,200mm, allowing manufacturers to streamline workflows while maintaining precision. This integration is particularly valuable for pilot lines and GW-scale factories, where space, time, and cost savings directly impact scalability. Lecheng’s "all-in-one" solution exemplifies how smart engineering can simplify complex production chains while boosting yield and consistency.

Customizable Optical Configurations for Diverse Process Needs

A key advantage of Lecheng’s multi-process systems is their modular optical architecture, which allows customization based on specific production requirements. The machine can be equipped with interchangeable laser sources and beam-splitting modules (supporting up to 24 beams), enabling tailored solutions for different perovskite cell structures or materials. For instance, P1 scribing may utilize a nanosecond infrared laser to cleanly remove TCO layers without damaging the glass substrate, while P2/P3 processes might employ picosecond green or UV lasers to precisely ablate perovskite and transport layers with minimal heat impact. The system’s software seamlessly switches between protocols, ensuring each step is optimized for accuracy (e.g., ±5μm positional tolerance) and minimal dead zone width (<150μm). This flexibility is further enhanced by features like trajectory tracking—where P2/P3 lines dynamically adapt to P1’s path—and focus following, which maintains consistent scribing depth on warped substrates. By accommodating varied laser parameters and beam configurations, Lecheng’s platform empowers manufacturers to experiment with new designs or scale proven processes without investing in separate tools.

Cost Efficiency and Operational Simplicity

Consolidating multiple perovskite processes into one machine delivers significant economic benefits. By reducing the number of required devices, manufacturers lower upfront capital investment, maintenance costs, and factory footprint. Lecheng’s systems also simplify operator training and process control—instead of managing several standalone machines, staff interact with a unified software interface that coordinates all laser operations. The integrated design minimizes alignment errors between process steps, improving overall yield. For example, the machine’s built-in HD monitoring and MES compatibility provide real-time data on each scribing stage, enabling quick adjustments and traceability. This is critical for high-volume production, where consistency directly impacts profitability. Additionally, the system’s compatibility with both rigid and flexible substrates (via roll-to-roll modules) extends its utility across diverse perovskite applications. By offering a scalable, user-friendly solution that balances precision with affordability, Lecheng lowers the barrier to entry for perovskite technology adoption, accelerating its transition from lab research to industrial commercialization.

Lecheng Intelligent’s multi-process laser systems redefine efficiency in perovskite solar cell manufacturing. By integrating scribing, cleaning, and customization capabilities into a single platform, they eliminate logistical bottlenecks while enhancing precision and scalability. As the perovskite industry advances toward commercialization, such all-in-one solutions will be instrumental in making solar energy more accessible and economically viable.