Laser Welding for Bipolar Plates

The Criticality of Bipolar Plates and the Advantages of Laser Welding

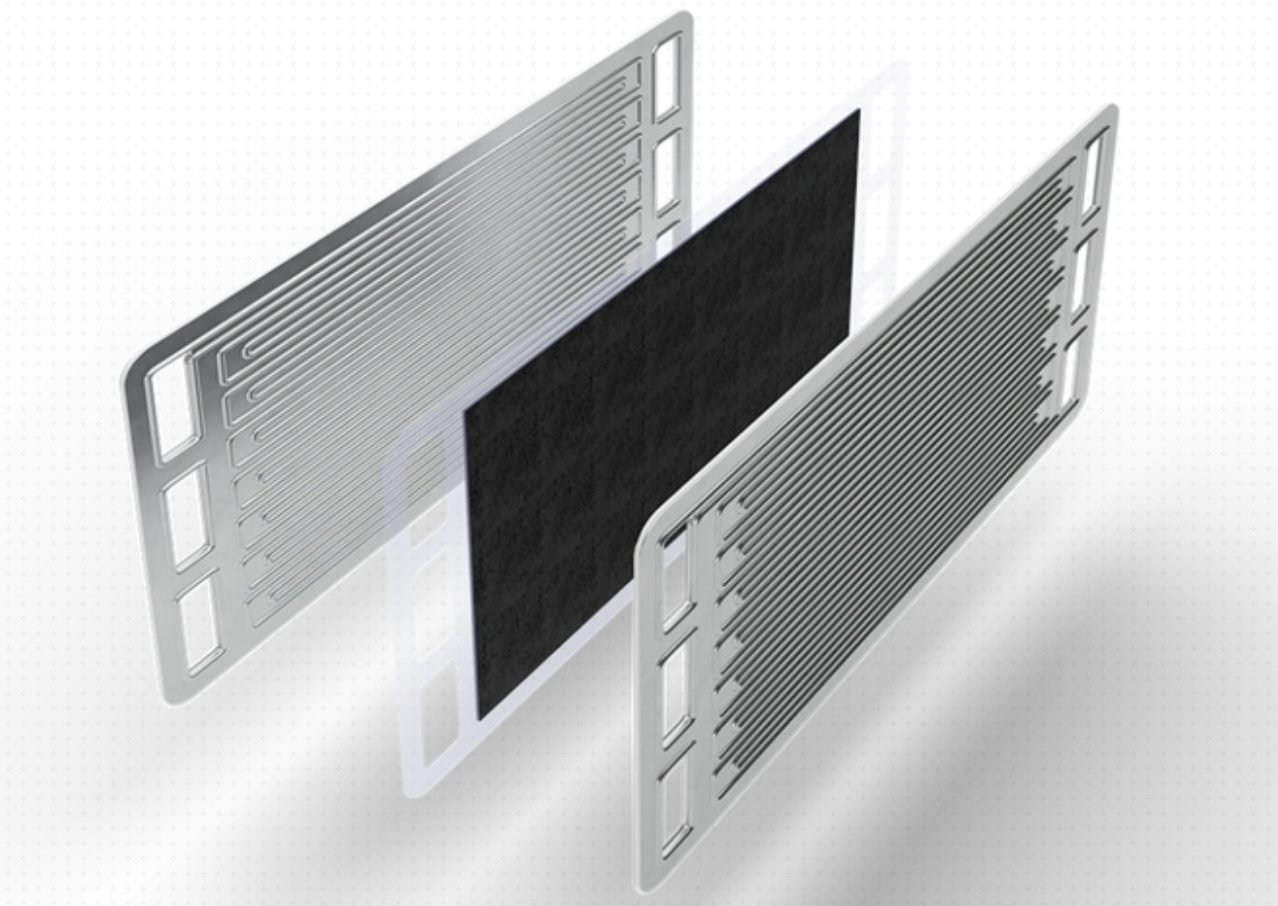

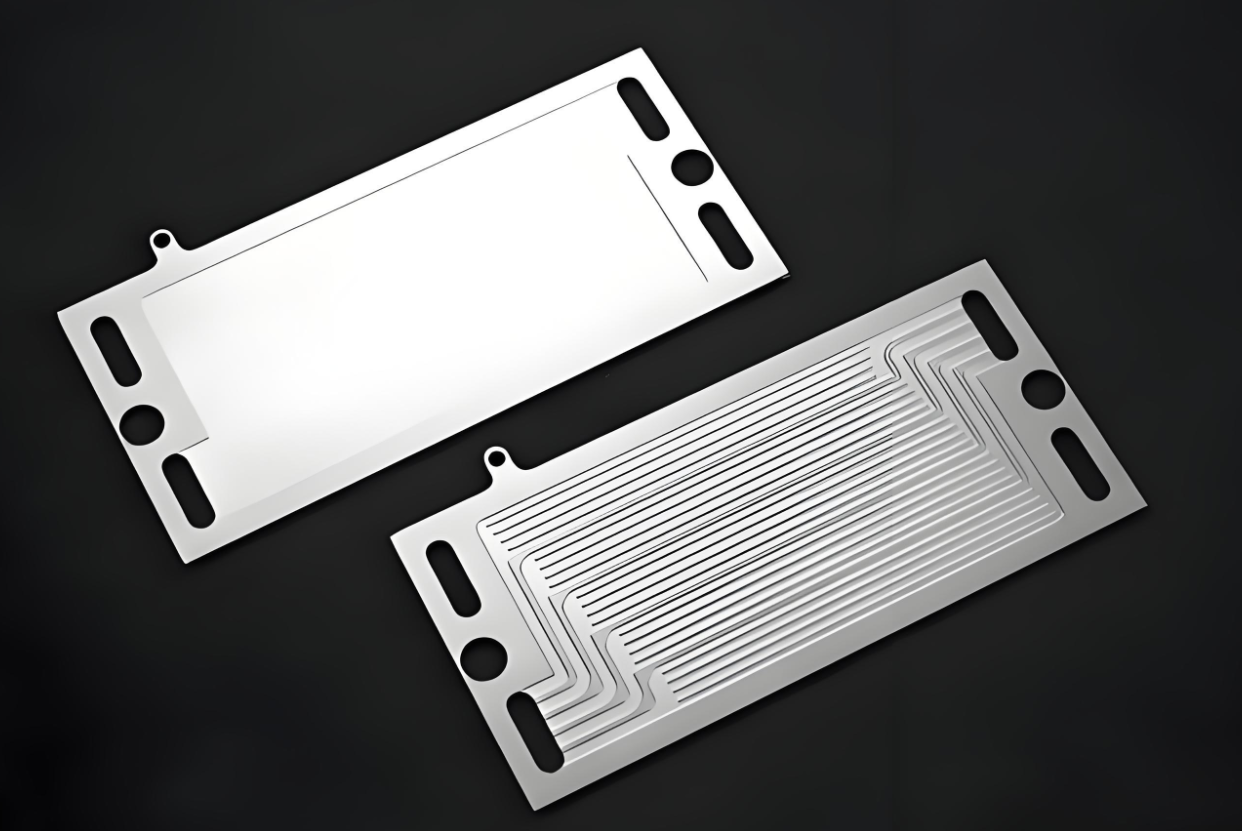

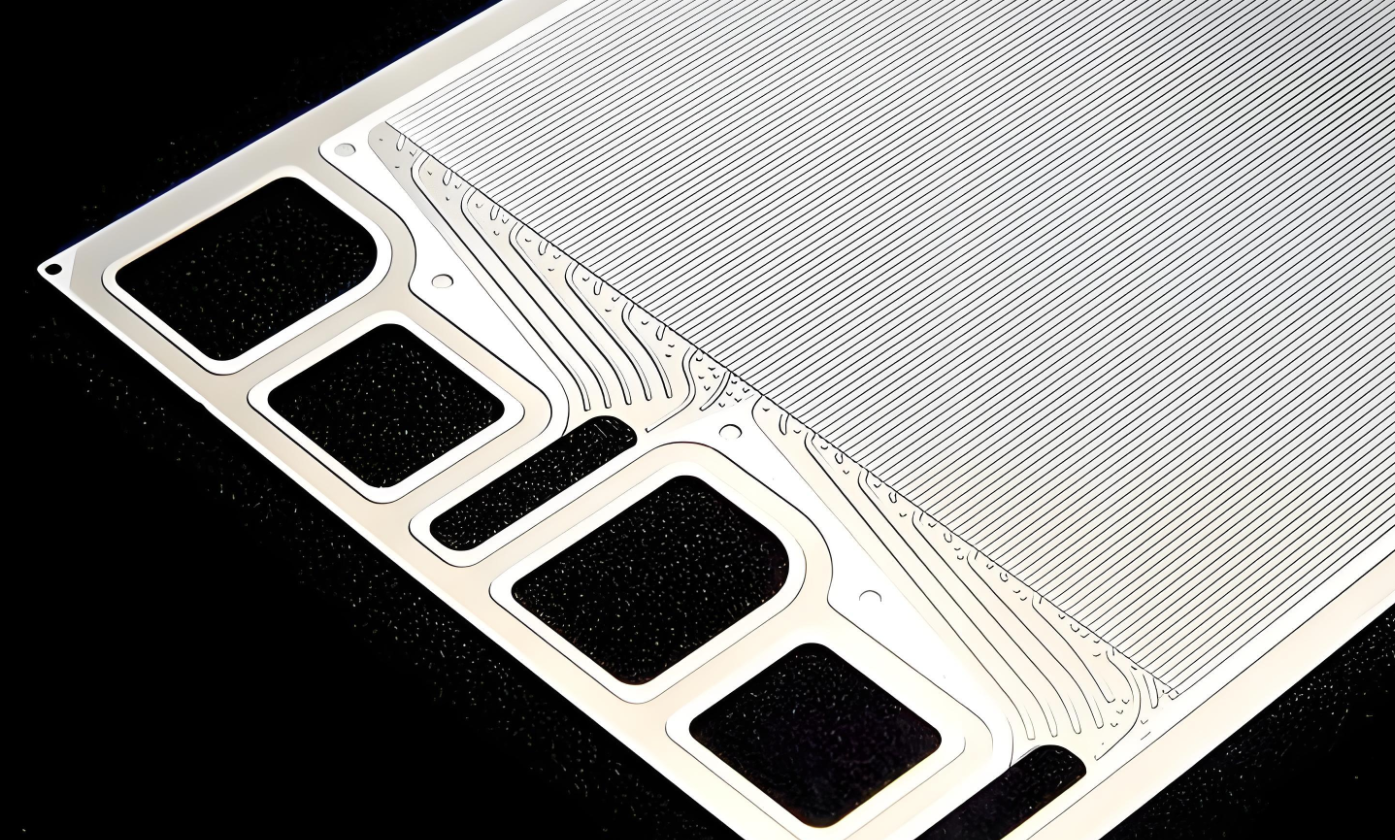

Bipolar plates (BPPs) are the backbone of hydrogen fuel cell stacks, serving multiple essential functions: distributing reaction gases (hydrogen and oxygen), conducting electrical current between cells, removing heat and water byproducts, and providing structural support. To prevent gas leakage and ensure long-term durability under varying pressures and temperatures, the sealing of these plates must be impeccable. Traditional welding methods often fall short due to excessive heat input, which can cause deformation, micro-cracks, or material degradation. Lecheng Intelligent’s laser welding technology addresses these challenges with high precision, minimal thermal stress, and exceptional consistency. By focusing energy into a microscopic spot (e.g., 0.08mm weld width), the laser creates hermetic seals without compromising the integrity of the delicate flow fields. This precision reduces the risk of leaks or corrosion, directly contributing to the fuel cell’s efficiency, longevity, and safety. For an industry striving to scale up production, Lecheng’s approach offers a repeatable, high-quality solution that meets the stringent demands of next-generation energy systems.

Lecheng’s Innovative Dual-Station Automated Welding System

Lecheng’s hydrogen fuel cell bipolar plate welding equipment features an advanced dual-laser-head, three-station design that maximizes production efficiency. While one station handles loading and unloading, the other two perform simultaneous welding operations, significantly reducing cycle times and increasing throughput. The system integrates robotics and high-precision vision modules for seamless plate handling and accurate alignment, ensuring repeatable positioning accuracy within 0.02mm. A key innovation is the proprietary fixture design that enables dual-sided welding, which is essential for complex plate geometries. The laser modules are equipped with real-time monitoring and automatic correction capabilities to maintain consistent weld quality, while integrated smoke purification systems ensure a clean processing environment. By combining PLC-controlled external axes with 4-axis linkage, the system achieves 5-axis motion flexibility, allowing it to adapt to various plate designs without retooling. This blend of automation, precision engineering, and adaptive control makes Lecheng’s system not just a welder, but a comprehensive manufacturing cell ready for integration into high-volume fuel cell production lines.

Enabling Scalable Production with Smart Manufacturing Capabilities

Beyond the welding process itself, Lecheng’s system is designed to support the scalability and traceability demanded by modern smart manufacturing. The equipment is fully compatible with Manufacturing Execution Systems (MES), enabling real-time data collection on weld parameters, quality metrics, and production status. This connectivity facilitates predictive maintenance, reduces downtime, and ensures every bipolar plate meets rigorous quality standards. Lecheng’s expertise in laser-material interaction ensures optimal weld profiles for different plate materials, including stainless steel and coated metals, minimizing porosity and enhancing mechanical strength. The company’s commitment to reliability is evident in features like dual-temperature-control cooling systems for lasers and welding heads, enabling continuous operation—a critical requirement for GW-scale fuel cell production. By providing a robust, data-driven welding solution, Lecheng Intelligent is not only supplying equipment but also empowering manufacturers to achieve the consistency and scale needed to make hydrogen fuel cells a commercially viable and sustainable energy alternative.

Lecheng Intelligent’s laser welding technology for bipolar plates represents a significant advancement in hydrogen fuel cell manufacturing. By delivering unmatched precision, automation, and smart manufacturing integration, Lecheng is helping overcome critical production barriers and driving the industry toward greater efficiency, reliability, and scalability. As hydrogen continues to gain prominence in the global energy transition, Lecheng’s innovations are positioned to play a vital role in shaping a sustainable energy future.