Lecheng’s Automatic Edge Cleaning Equipment for Perovskite Modules

The Critical Role of P4 Edge Isolation in Module Performance and Reliability

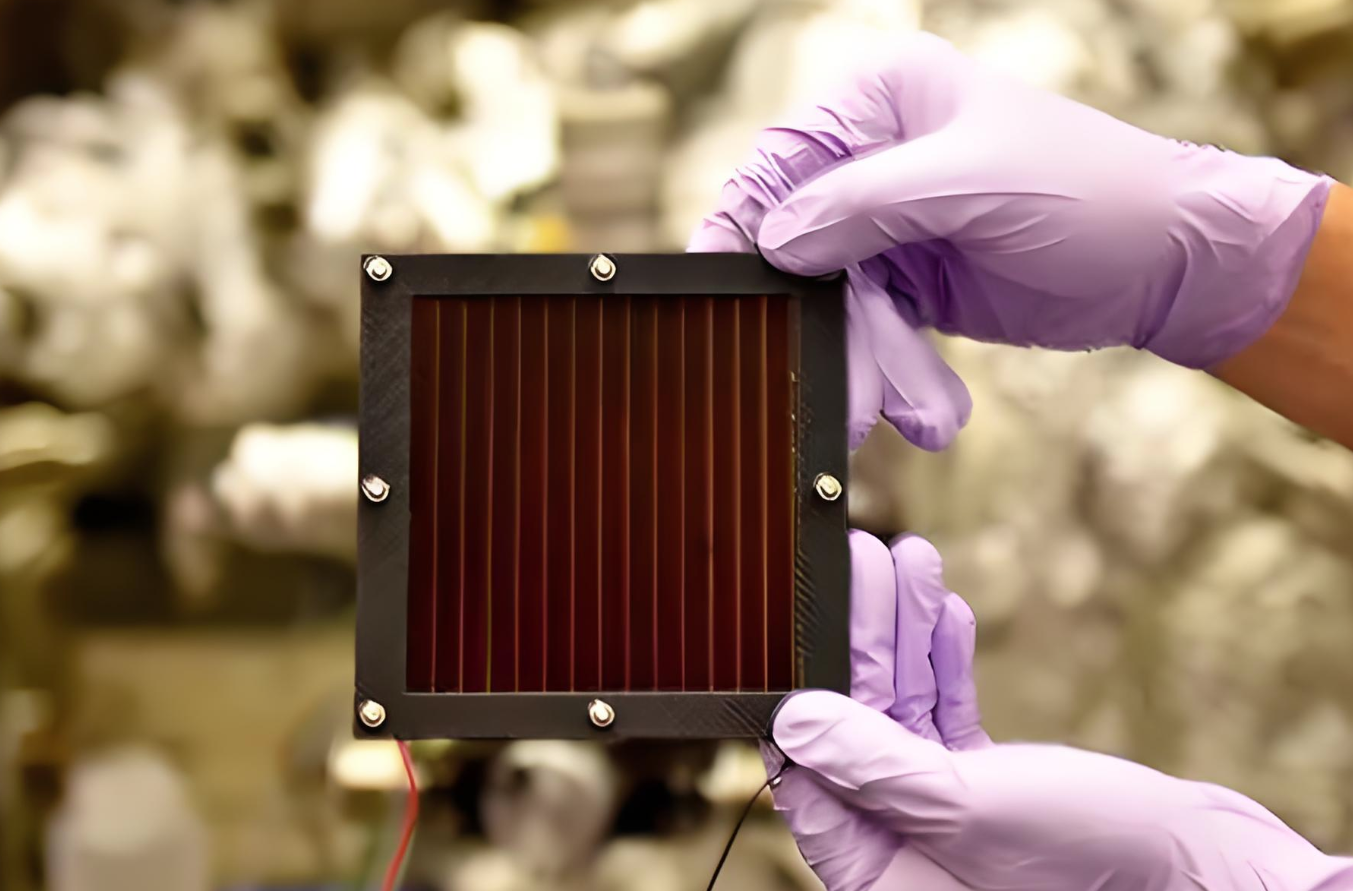

Following the intricate P1, P2, and P3 laser scribing processes that define the active cell areas in a perovskite solar module, the P4 laser edge cleaning (or edge isolation) step is a final yet crucial procedure for ensuring product quality and long-term reliability. The purpose of P4 is to use laser technology to completely remove the thin-film layers deposited near the four edges of the glass substrate. This process creates a clean, insulating border around the entire module. If these conductive and semi-conductive layers (TCO, perovskite, HTL, ETL, and electrode) are left extending to the very edge, they can create electrical leakage paths, leading to power loss and potential short circuits. Furthermore, unremoved edge films can compromise the adhesion and hermeticity of the subsequent encapsulation materials, which is critical for protecting the moisture-sensitive perovskite layer from degradation. Lecheng Intelligent's Automatic Edge Cleaning Equipment is specifically engineered to address this challenge with high precision and efficiency, ensuring that every module leaving the production line has a clean, insulated perimeter that is essential for achieving high insulation resistance, stable performance, and extended operational lifespan. This makes the P4 process not just a cleaning step, but a vital guarantor of module durability.

Advanced Engineering for High-Precision and High-Throughput Cleaning

Lecheng's Automatic Edge Cleaning Equipment (AFC10 series) is designed for seamless integration into industrial perovskite production lines, capable of handling large-format modules up to 2.4m x 1.2m. A key structural innovation is the integration of the processing station directly with the material transmission line. This design solves the challenge of handling and repositioning large, fragile glass substrates during the cleaning process, significantly improving operational efficiency and reducing the risk of breakage. The core of the cleaning action utilizes high-speed galvanometer scanners, enabling "on-the-fly" processing where the laser beam moves rapidly across the module edge as the substrate passes through, dramatically increasing the processing speed compared to traditional step-and-repeat methods. For precise alignment, the system employs a combination of mechanical and advanced vision positioning. High-resolution cameras accurately identify the exact edge of the deposited film, ensuring the laser path is perfectly aligned to remove all unwanted material without encroaching on the active area. This results in a consistent and precise cleaning width. The equipment is typically equipped with high-power nanosecond infrared lasers (e.g., 1064nm wavelength), which provide the necessary energy to efficiently ablate the various film layers while maintaining a high processing speed essential for mass production. This combination of robust automation, high-speed scanning, and intelligent positioning makes the system both highly accurate and exceptionally productive.

Ensuring Process Control and Seamless Production Line Integration

Beyond the core cleaning function, Lecheng's equipment is built with comprehensive monitoring and control features to ensure process stability and ease of integration. The system is powered by Lecheng's fully self-developed control software, which offers exceptional flexibility and stability. Operators can easily set and adjust cleaning parameters, such as laser power, scanning speed, and cleaning path, for different product specifications. A critical feature for quality assurance is the integrated high-definition monitoring system. This system continuously records and stores real-time video of the cleaning process inside the equipment, allowing for immediate inspection and facilitating traceability for any production issues. This is invaluable for maintaining high yields and rapid troubleshooting. Additionally, the machine is equipped with an effective dust collection system that captures ablation particles generated during the cleaning process, maintaining a clean internal environment and preventing contamination. The three-station design (loading, processing, unloading) allows the equipment to be easily integrated into an automated production line, enabling continuous flow manufacturing. Lecheng's engineers provide expert on-site support for installation, commissioning, and process debugging, ensuring a smooth transition to production. This focus on robust software, real-time monitoring, and excellent after-sales service makes Lecheng's edge cleaning equipment a reliable and smart choice for perovskite manufacturers aiming for scalable and stable mass production.

Lecheng Intelligent's Automatic Edge Cleaning Equipment represents a critical piece of the perovskite module manufacturing puzzle. By delivering a robust, high-precision, and automated solution for the essential P4 process, Lecheng ensures that perovskite modules not only achieve their initial efficiency potential but are also built to last. This technology is indispensable for translating the laboratory promise of perovskite solar cells into reliable, commercially viable products for the global energy market.