High-Speed Dual-Station Laser Welding System for Fuel Cell Stacks

Revolutionizing Fuel Cell Production with Advanced Automation

The transition to hydrogen energy hinges on the ability to manufacture fuel cell stacks efficiently and reliably. Lecheng Intelligent's High-Speed Dual-Station Laser Welding System addresses this need with an innovative three-station design that seamlessly integrates loading, welding, and unloading processes. This configuration features dual laser modules operating concurrently while a third station manages material handling, effectively eliminating downtime and maximizing throughput. The system's robotic arms, equipped with advanced vision systems, ensure precise positioning of bipolar plates with an accuracy of ±0.02mm. This level of automation is crucial for maintaining consistency in weld quality across high-volume production runs. By integrating laser welding with smart automation, Lecheng enables manufacturers to achieve unprecedented production speeds while maintaining the stringent quality standards required for fuel cell applications. The system's modular design also allows for flexible adaptation to different stack sizes and configurations, making it an ideal solution for both current and future fuel cell technologies.

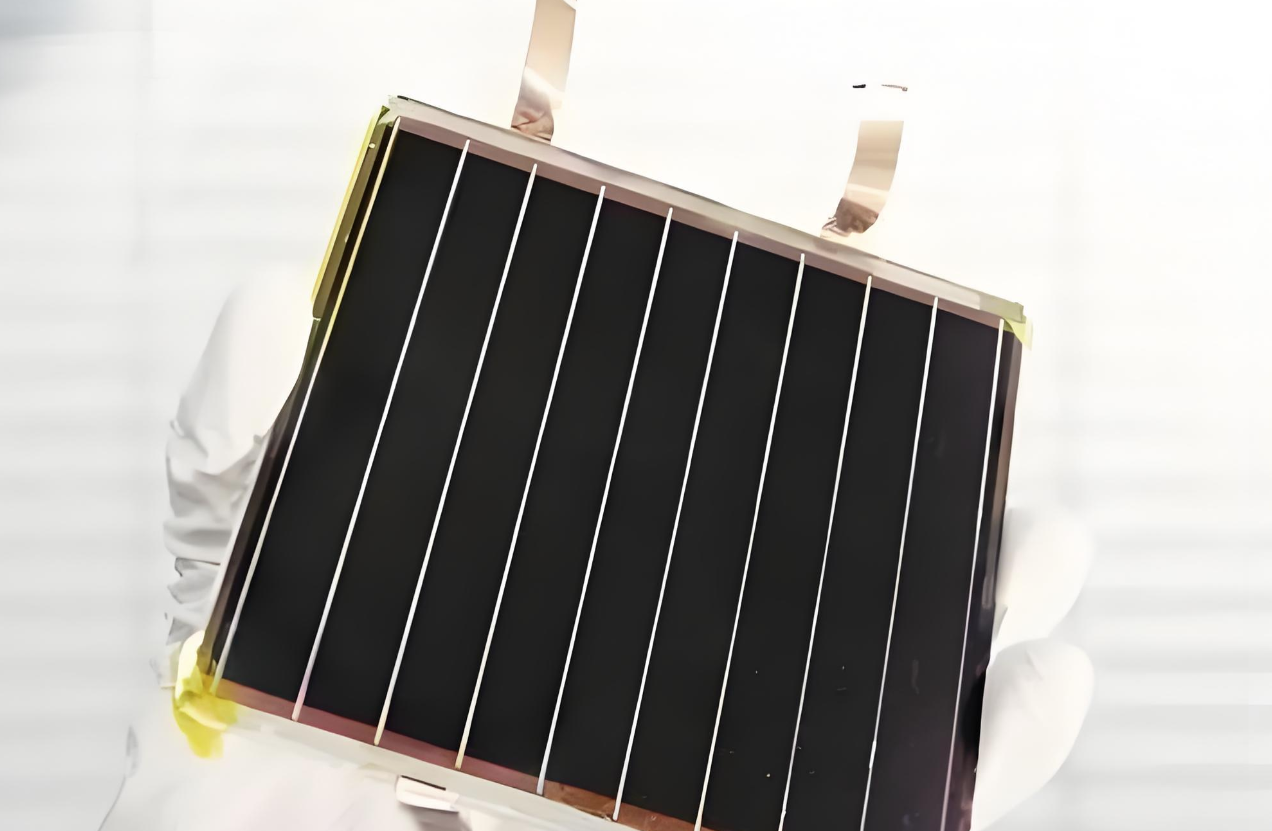

Precision Engineering for Critical Sealing Applications

At the heart of Lecheng's system lies its precision welding technology, specifically engineered for the demanding requirements of bipolar plate sealing. The system achieves remarkable weld widths of just 0.08mm while maintaining consistent penetration depth, ensuring complete sealing without compromising the integrity of the delicate flow fields. This precision is made possible through advanced features like real-time focus tracking and automatic compensation systems that maintain optimal welding parameters throughout the process. The dual-temperature-control cooling system ensures stable operation of both lasers and welding heads, enabling continuous 24/7 production cycles. What sets Lecheng apart is its proprietary fixture design that facilitates dual-sided welding access, allowing for complex weld patterns and geometries. The integration of smoke purification systems maintains a clean processing environment, while high-definition monitoring provides complete process visibility. These engineering innovations collectively ensure that every weld meets the rigorous standards required for fuel cell applications, where even minor imperfections can lead to performance issues or failure.

Smart Manufacturing Integration for Scalable Production

Lecheng's system transcends traditional welding equipment by incorporating comprehensive smart manufacturing capabilities. Full MES (Manufacturing Execution System) compatibility enables real-time data collection and analysis, providing manufacturers with complete visibility into production metrics, quality parameters, and equipment performance. This connectivity facilitates predictive maintenance strategies, reducing unplanned downtime and optimizing operational efficiency. The system's data-driven approach allows for continuous process optimization, with weld parameters automatically adjusted based on real-time feedback. This is particularly valuable for fuel cell production, where consistent quality is paramount. Lecheng's expertise in laser-material interaction ensures optimal performance across various plate materials, from stainless steel to specialized coatings. The company's focus on scalability is evident in the system's ability to maintain precision welding quality while achieving production speeds necessary for GW-scale manufacturing. By combining precision engineering with Industry 4.0 technologies, Lecheng provides not just a welding system, but a complete manufacturing solution that supports the transition to large-scale hydrogen fuel cell production.

Lecheng Intelligent's High-Speed Dual-Station Laser Welding System represents a significant leap forward in fuel cell manufacturing technology. By combining precision engineering with advanced automation and smart manufacturing capabilities, Lecheng is enabling the scalable production of high-quality fuel cell stacks. As the hydrogen economy continues to evolve, solutions like this will play a crucial role in making clean energy more accessible and commercially viable. Lecheng's commitment to innovation and quality positions them as a key enabler in the global transition to sustainable energy systems.