Picosecond Laser Ablation Enables Coverlay Opening by Replacing Wet Processes

The Limitations of Wet Etching in Modern FPC Manufacturing

Traditional methods for creating openings in the coverlay (CVL) of Flexible Printed Circuits (FPCs) have long relied on wet chemical etching processes. This technique involves using photoresist, exposure, development, and chemical baths to remove the polyimide or acrylic coverlay material, exposing the underlying copper pads for component soldering or electrical connection. While established, this method presents significant drawbacks in today's demanding electronics manufacturing environment. It is a multi-step, time-consuming process that consumes large volumes of chemicals and water, raising environmental concerns and disposal costs. The process also struggles with precision, especially as the demand for miniaturization increases, making it difficult to achieve clean, well-defined openings for high-density interconnects (HDI). There is a clear industry need for a more precise, environmentally friendly, and efficient alternative that can keep pace with the evolution of electronic devices. Lecheng Intelligent's laser technology offers this exact solution, marking a paradigm shift in coverlay processing.

The Precision and Efficiency of Picosecond Laser Ablation

Lecheng Intelligent's advanced laser systems utilize ultra-short pulse picosecond lasers to ablate coverlay material with exceptional precision, completely eliminating the need for wet chemicals. The core of this technology lies in the extremely short pulse duration of the laser, which acts on a picosecond (10⁻¹² seconds) timescale. This rapid energy deposition vaporizes the organic coverlay material directly into a plasma state before significant heat can transfer to the surrounding area. This "cold ablation" process results in a minimal Heat-Affected Zone (HAZ), which Lecheng's technology controls to under 50μm. This is critical for preventing damage to adjacent circuits and delicate base materials. Lecheng's equipment can achieve minimum opening sizes of 100μm, meeting the stringent requirements for modern, compact electronics. The process is digitally controlled from CAD data, allowing for rapid prototyping and easy design changes without the need for new photomasks. This offers unparalleled flexibility and significantly reduces time-to-market for new FPC designs. The system's high-speed galvanometers enable fast processing, making it not only cleaner but also highly competitive in terms of throughput for mass production.

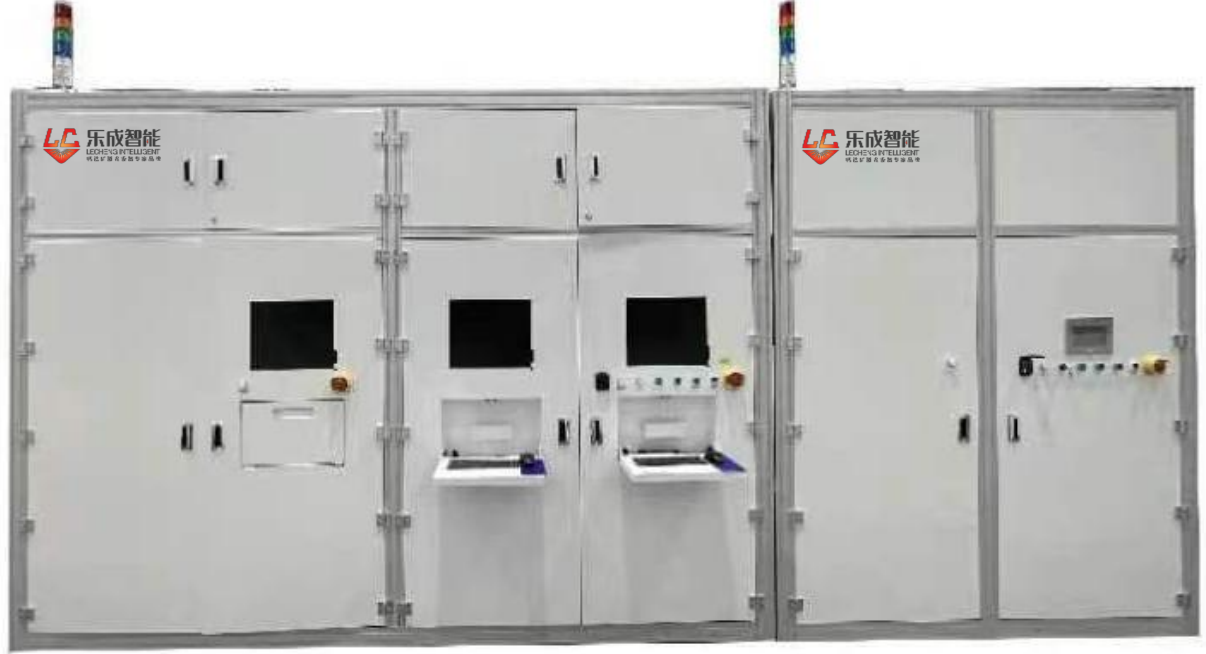

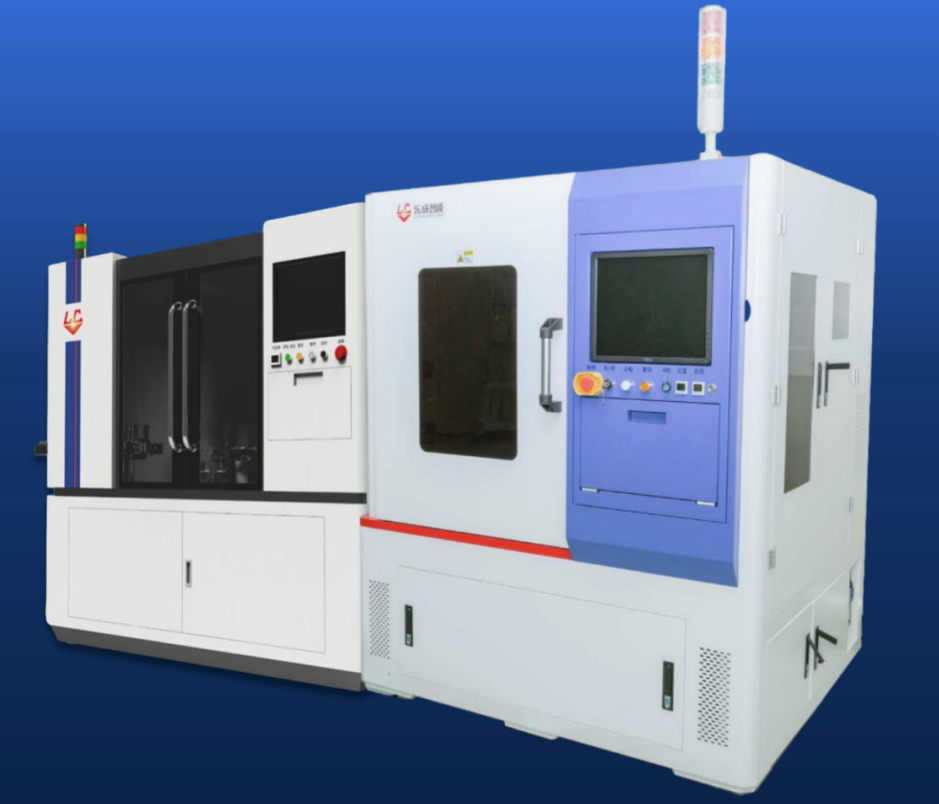

Lecheng's Integrated Laser Solution for Superior Results

Lecheng Intelligent provides more than just a laser source; it offers a fully integrated, automated solution engineered for reliability and ease of integration into existing FPC production lines. Their systems feature precision motion stages that support large processing formats up to 650mm x 550mm, accommodating panel-level processing for higher efficiency. The heart of the system is Lecheng's self-developed control software, which offers high flexibility and stability, allowing operators to easily define and adjust opening patterns, sizes, and parameters. Automated vision systems are incorporated for precise pattern recognition and alignment, ensuring accurate registration with the underlying circuit traces. This eliminates the misalignment issues common in traditional processes. Furthermore, the systems are equipped with integrated dust removal units to maintain a clean processing environment and ensure consistent, high-quality results. By replacing wet etching, Lecheng's laser ablation solution drastically reduces water consumption and chemical waste, supporting the electronics industry's goals for greener manufacturing. The dry, maskless process simplifies the workflow, reduces operational costs associated with chemical handling and disposal, and delivers a superior, more reliable product.

The transition from wet chemical etching to picosecond laser ablation for coverlay opening represents a significant technological leap forward. Lecheng Intelligent is at the forefront of this shift, providing manufacturers with a tool that enables higher precision, greater design freedom, improved sustainability, and enhanced production efficiency. As FPCs continue to become smaller and more complex, Lecheng's laser technology is poised to become the new industry standard, empowering the next generation of electronic innovation.