Lecheng’s Solution for Semiconductor and FPC Manufacturing

Ultrafine Laser Etching for High-Density Circuitry

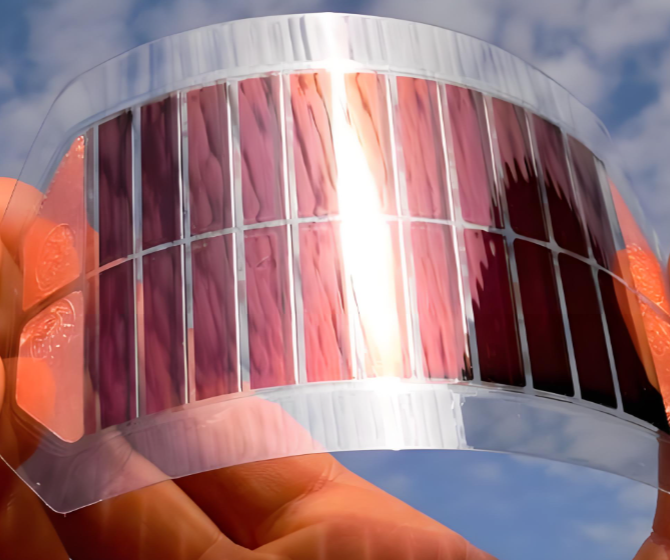

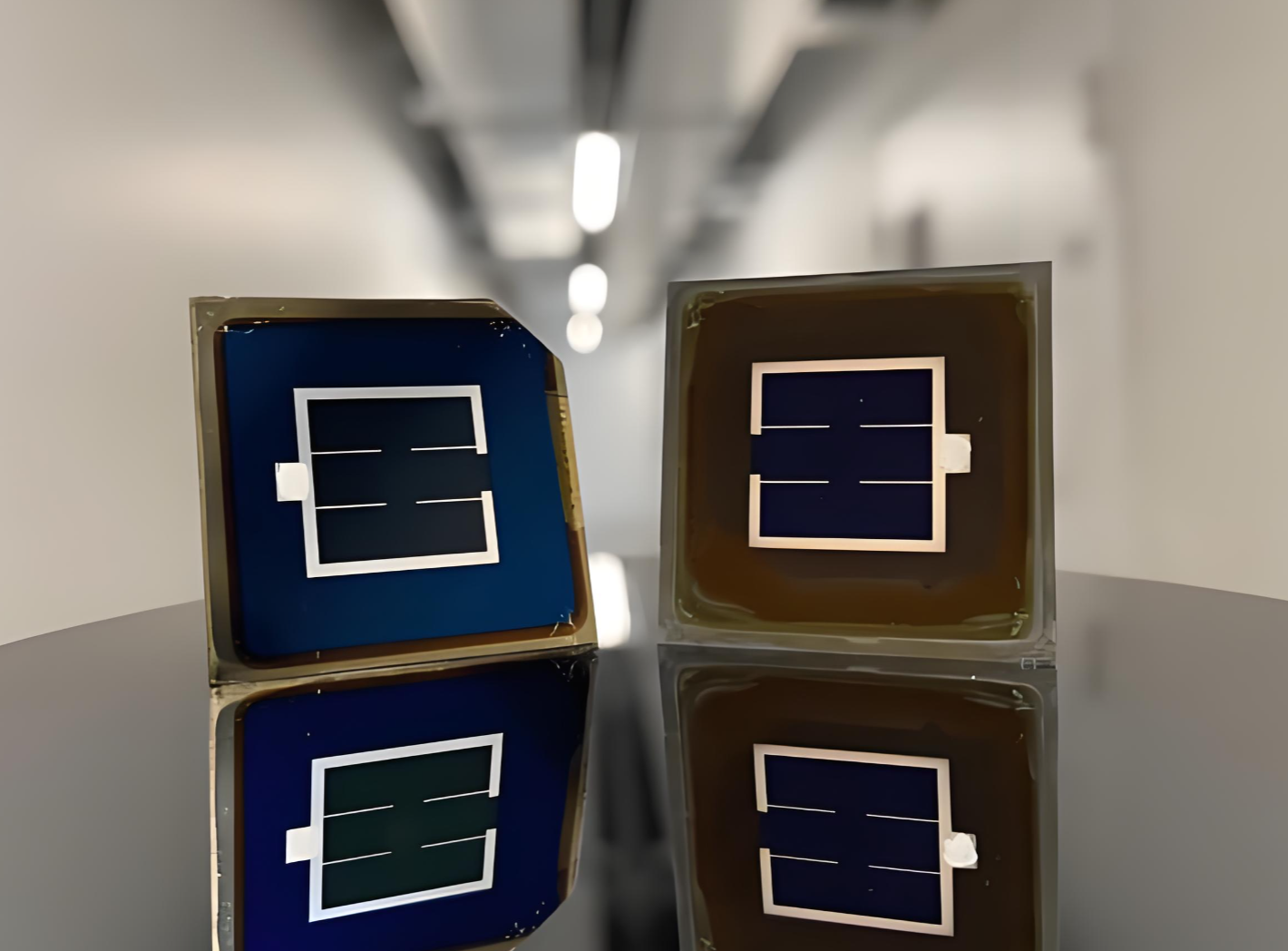

Lecheng's laser etching equipment achieves remarkable precision with a minimum line width of 5μm, enabling the production of high-density interconnects essential for advanced semiconductors and flexible printed circuits (FPCs). By utilizing ultrashort pulse lasers (e.g., picosecond UV), the system minimizes heat-affected zones (HAZ) to below 10μm, preventing damage to delicate substrates. This non-contact process supports curved-surface patterning, making it ideal for flexible electronics. With speeds up to 2000mm/s—four times faster than chemical etching—Lecheng’s technology eliminates waste and reduces operational costs while maitaining ±2μm accuracy. The equipment’s compatibility with over 200 materials, including polyimide and copper-clad laminates, ensures versatility across FPC manufacturing steps, from trace definition to via drilling.

Precision Drilling and Cutting for Advanced Packaging

Lecheng's HDI microvia drilling systems excel in creating sub-50μm vias with exceptional consistency, critical for high-density interconnect (HDI) boards used in 5G and IoT devices. The equipment integrates automatic focus control and ultra-fast galvanometer scanners, achieving throughputs of 300 holes/second for 100μm apertures. For semiconductor lead frames and rigid-FPC hybrids, Lecheng's laser cutting systems handle materials like tungsten and ceramics with ≤10μm kerf widths and HAZ below 15μm. The dual-chuck design enables continuous processing, reducing idle time by 30%. These capabilities are enhanced by proprietary path-planning algorithms that optimize tool trajectories for maximum efficiency.

Integrated Automation and Smart Manufacturing Compatibility

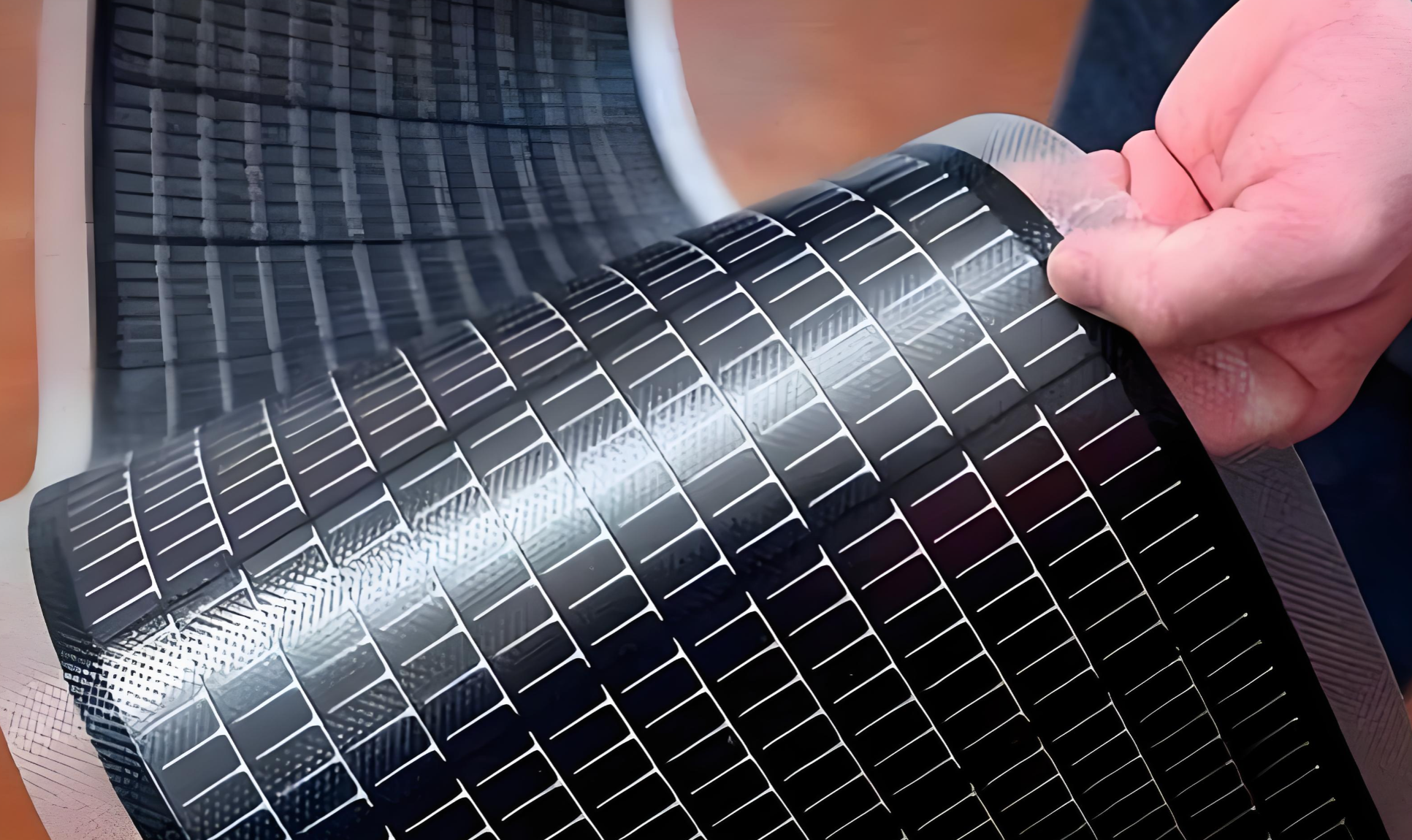

Lecheng's solutions emphasize seamless integration into existing production lines through modular designs and Industry 4.0-ready interfaces. The laser etching and drilling systems feature robotic arms for automated loading/unloading, reducing manual intervention by 70%. Real-time monitoring via high-resolution cameras ensures consistent quality, while CAD/CAM compatibility allows rapid prototyping and customization. For FPC manufacturers, Lecheng's technology supports roll-to-roll processing for large-scale flexible circuit production, with capabilities like 100μm window opening in cover layers and selective ink removal. This adaptability, combined with cloud-based data analytics, enables predictive maintenance and reduces downtime by 25%.

Lecheng's laser solutions bridge the gap between precision microprocessing and industrial scalability, offering semiconductor and FPC manufacturers a competitive edge through faster throughput, superior accuracy, and smart automation.